Shield tail sealing grease as well as preparation method and application thereof

A shield tail seal and grease technology, applied in the field of seal grease, can solve the problems of high price and high use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

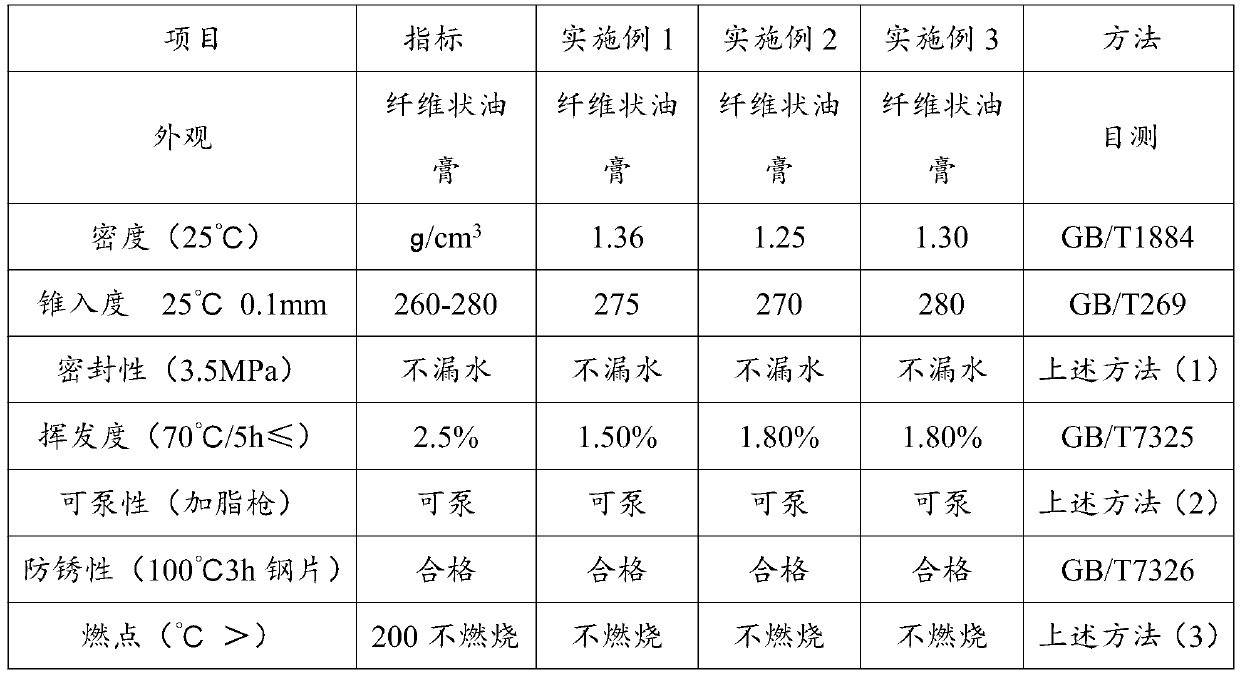

Examples

preparation example Construction

[0030] The present invention also provides the preparation method of described shield tail sealing grease, comprising the following steps:

[0031] Anhydrous calcium-based lubricating grease, asbestos fiber, calcium carbonate, high molecular polymer, petroleum resin and antirust agent are mixed to obtain the shield tail sealing grease.

[0032] In the present invention, the mixing preferably includes the following steps:

[0033] performing the first mixing of the anhydrous calcium-based grease, high molecular polymer and petroleum resin to obtain a first mixture;

[0034] The first mixture and calcium carbonate are mixed for a second time to obtain a second mixture;

[0035] The second mixture, the asbestos fiber and the antirust agent are mixed for the third time to obtain the shield tail sealing grease.

[0036] In the present invention, the anhydrous calcium-based lubricating grease, high molecular polymer and petroleum resin are first mixed to obtain the first mixture. ...

Embodiment 1

[0045] At 25°C, 25g of anhydrous calcium-based grease, 2g of polyisobutylene and 1g of 120 petroleum resin were mechanically stirred and kneaded (the stirring speed was 30rpm, and the stirring time was 1h) to obtain the first mixture;

[0046] At 30° C., the first mixture and 35 g of calcium carbonate (1100 mesh) were mechanically stirred and mixed (the stirring speed was 30 rpm, and the stirring time was 1 h) to obtain the second mixture;

[0047] At 50° C., the first mixture, 35 g of asbestos fibers (2 mm), and 2 g of barium petroleum sulfonate were mechanically stirred and mixed (the stirring speed was 30 rpm, and the stirring time was 2 h) to obtain shield tail seal grease.

Embodiment 2

[0049] At 50° C., 30 g of anhydrous calcium-based grease, 3 g of polyisobutylene and 2 g of 120 petroleum resin were mechanically stirred and kneaded (the stirring speed was 30 rpm, and the stirring time was 1 h) to obtain the first mixture;

[0050] At 30°C, the first mixture and 32g of calcium carbonate (1100 mesh) were mechanically stirred and mixed (the stirring speed was 30rpm, and the stirring time was 1h) to obtain the second mixture;

[0051] At 35° C., the second mixture, 30 g of asbestos fibers (1.5 mm) and 2 g of barium petroleum sulfonate were mechanically stirred and mixed (stirring speed was 40 rpm, stirring time was 2 h) to obtain shield tail seal grease.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com