Aluminum alloy strip material for computer support, and preparation method thereof

An aluminum alloy strip and an aluminum alloy technology, which are applied in the field of aluminum alloy strips for computer brackets and their preparation, can solve problems such as unfavorable formability, reduction of alloy plasticity, deterioration of pressure processing performance, etc., and achieve good anodic oxidation quality, Effect of reducing material brittleness and optimizing production parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

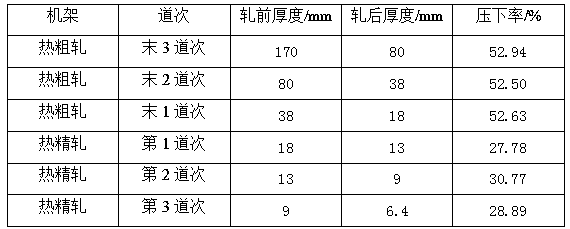

Image

Examples

Embodiment 1

[0031] The composition of an aluminum alloy strip for a computer bracket and a manufacturing method thereof is calculated as: Si 0.05%, Fe 0.05%, Cu 0.03%, Mn 0.025%, Mg 3.0%, Cr 0.03%, Zn 0.01%, Ti 0.012%, the balance is Al and inevitable impurities.

[0032] The preparation method of the aluminum alloy strip for the computer bracket is as follows:

[0033] 1) Add aluminum ingots, aluminum master alloy ingots, magnesium ingots and manganese agent into the smelting furnace in proportion, and after melting, refining, slag removal, and stirring at 730 ° C, the stirring speed is 80 r / min, and the formed aluminum The liquid was placed in a standing furnace for 2.0 h;

[0034] 2) Add a grain refiner to the molten aluminum at 700°C, the refiner is Al-5Ti-0.2B, and the addition amount is 60~120ppm. After refining by argon gas, the refined aluminum liquid is cast into aluminum alloy flat ingot by semi-continuous casting method, and the thickness of the ingot is 400mm;

[0035] 3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com