A kind of sulfonamide aromatic polymer, its preparation method and application

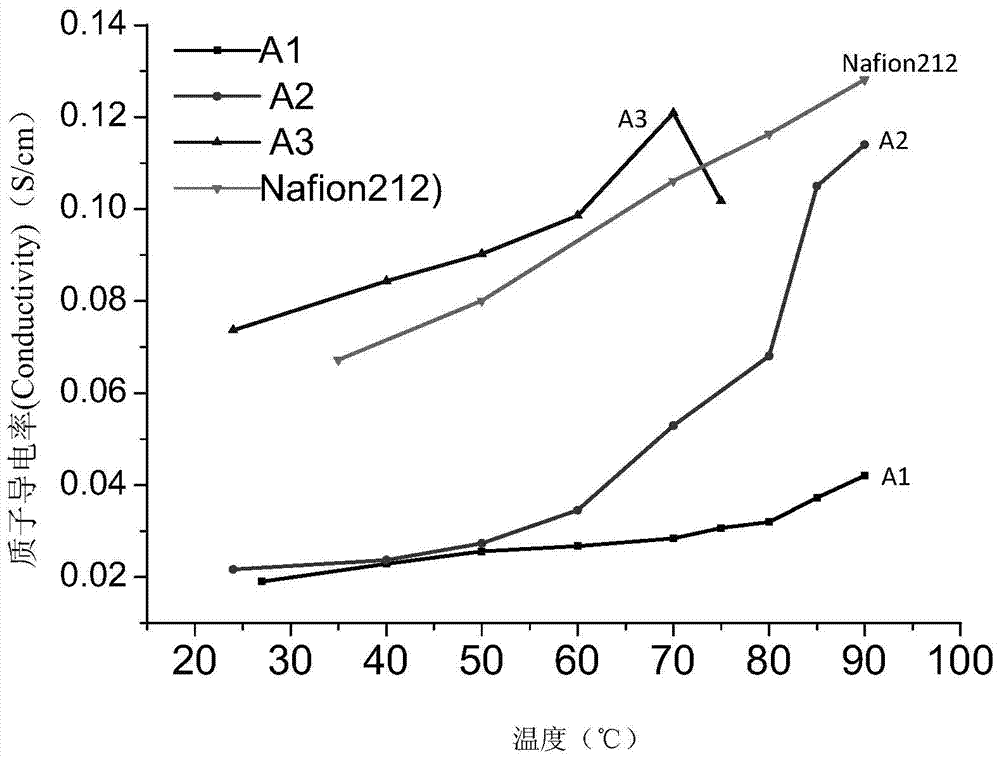

An aromatic polymer and sulfonamidation technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of enhanced water absorption of ion membranes, weak ion conductivity, and poor chemical stability, etc., to achieve Easy handling, simple composition, enhanced barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

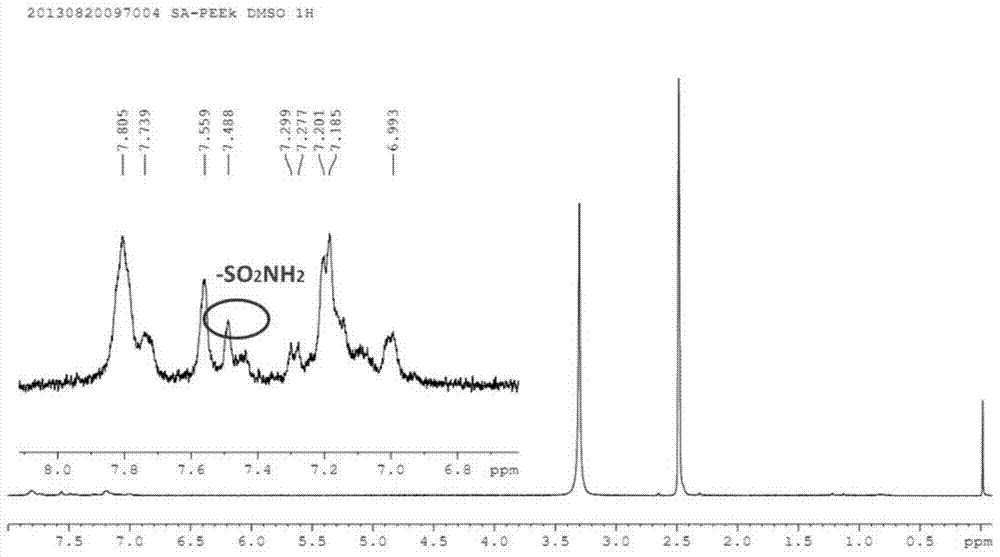

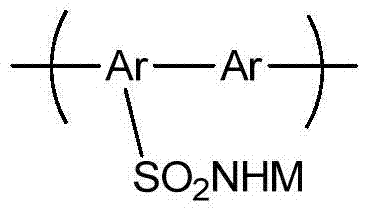

[0039] In this embodiment, the sulfonamidated polyaromatic polymer is a polymer with polyether ether ketone as its main chain and benzenesulfonamide groups as its side chains. The polymer uses polyether ether ketone as raw material, sulfuric acid as sulfonation reagent, thionyl chloride as acyl chloride reagent, liquid ammonia as amidation reagent, and is prepared through reactions such as acyl chloride and amidation.

[0040] Concrete preparation method comprises the following steps:

[0041] Step 1: In a 50ml three-neck flask, add 20ml of concentrated sulfuric acid with a concentration of 98% by mass, then stir and add 1g of polyether ether ketone resin powder, heat up to 40°C, and perform sulfonation reaction for 12h; after the reaction, pour the reaction product into ice water, the resin is precipitated, and fully washed with deionized water to obtain sulfonated polyether ether ketone resin.

[0042] Step 2: Add the sulfonated polyether ether ketone resin obtained in step...

Embodiment 2

[0049] In this embodiment, the sulfonamidated polyaromatic polymer is a polymer with polysulfone as its main chain and benzenesulfonamide groups as its side chains. The polymer is prepared by taking polysulfone as raw material, chlorosulfonic acid as sulfonating reagent and acyl chloride reagent, ammonia as amidation reagent, and is prepared through reactions such as acyl chloride and amidation.

[0050] Concrete preparation method comprises the following steps:

[0051] Step 1: In a 50ml three-neck flask, add 20ml of dichloromethane, then stir and add 1g of polysulfone resin particles, after dissolving, slowly drop in 3ml of chlorosulfonic acid dissolved in 10ml of dichloromethane, and put it in an ice-water bath React for 3 hours; after the reaction, pour the reaction product into ice water to precipitate the resin, wash it thoroughly with deionized water, and freeze-dry to obtain the sulfonyl chloride polysulfone resin.

[0052] Step 2: Put the sulfonyl chloride polysulfon...

Embodiment 3

[0058] In this embodiment, the sulfonamidated polyaromatic polymer is a polymer with polyether ether ketone as its main chain and benzenesulfonamide groups as its side chains. The polymer uses polyether ether ketone as raw material, fuming sulfuric acid as sulfonation reagent, phosphorus oxychloride as acyl chloride reagent, ammonia water as amidation reagent, and is prepared through sulfonation, acyl chloride, amidation and other reactions.

[0059] Concrete preparation method comprises the following steps:

[0060] Step 1: In a 50ml three-neck flask, add 20ml of concentrated sulfuric acid with a concentration of 98% by mass, then stir and add 1g of polyetheretherketone resin powder, slowly add 5ml of oleum dropwise, and react for 2 hours; pour the reaction product into ice water , the resin is precipitated, and the resin is fully washed with deionized water to obtain a sulfonated polyether ether ketone resin.

[0061] Step 2: Add the sulfonated polyetheretherketone resin ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com