Prefabricated steel plate shear wall system with two anti-seismic defense lines

A steel plate shear wall, fabricated technology, applied in the direction of walls, earthquake-proof, protective buildings/shelters, etc., can solve the problems of insufficient lateral force resistance and energy dissipation performance, large welding workload, buckling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

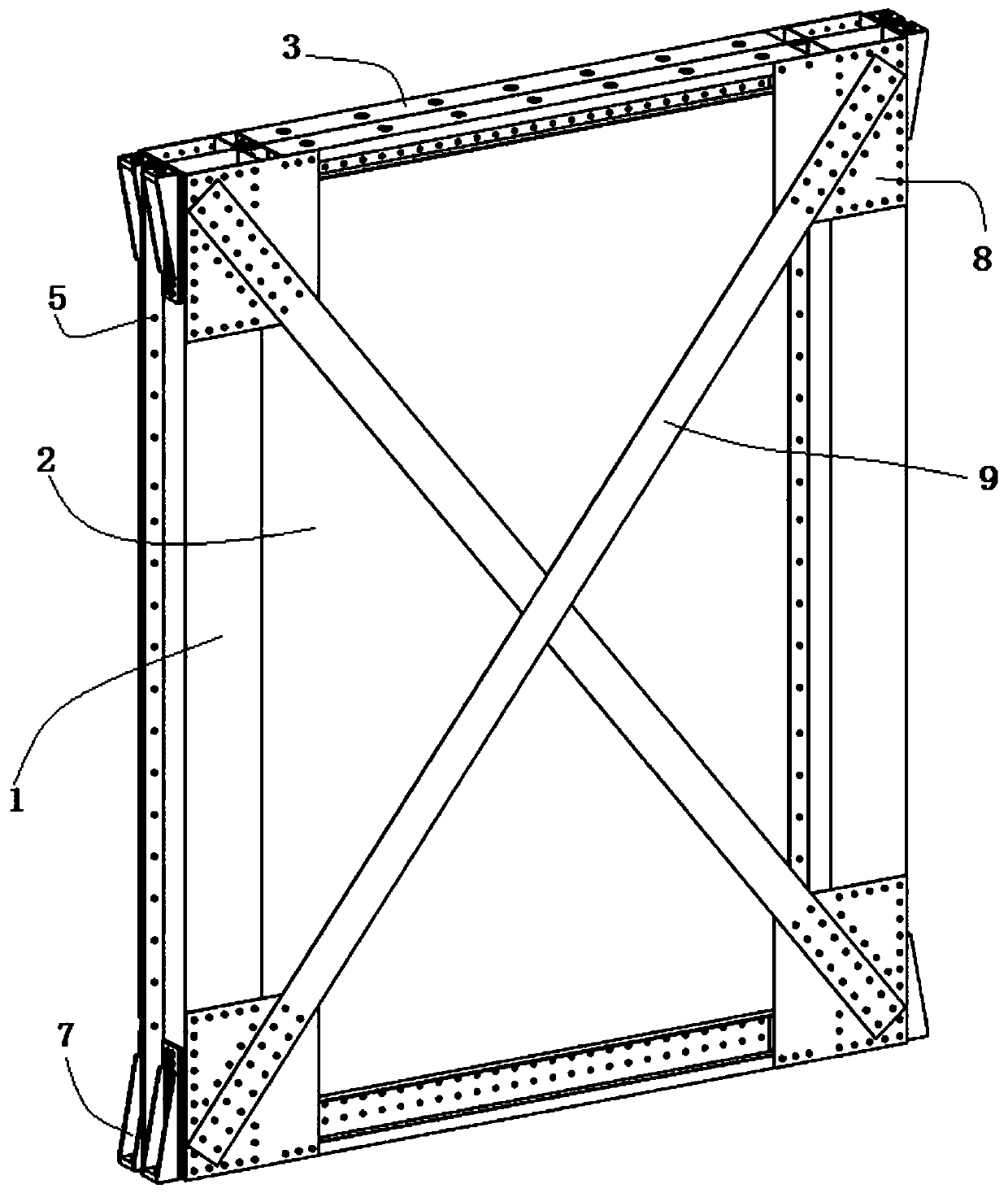

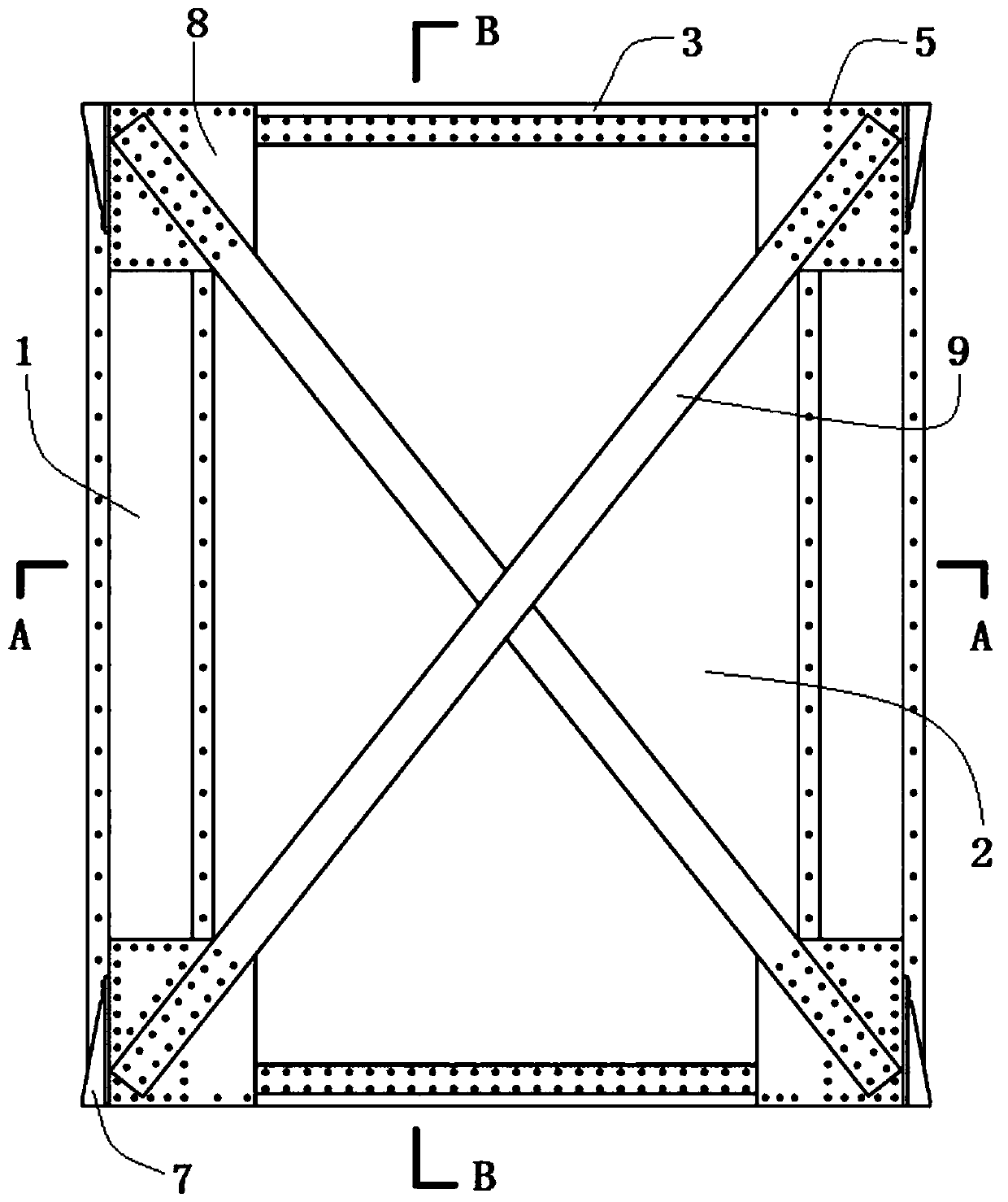

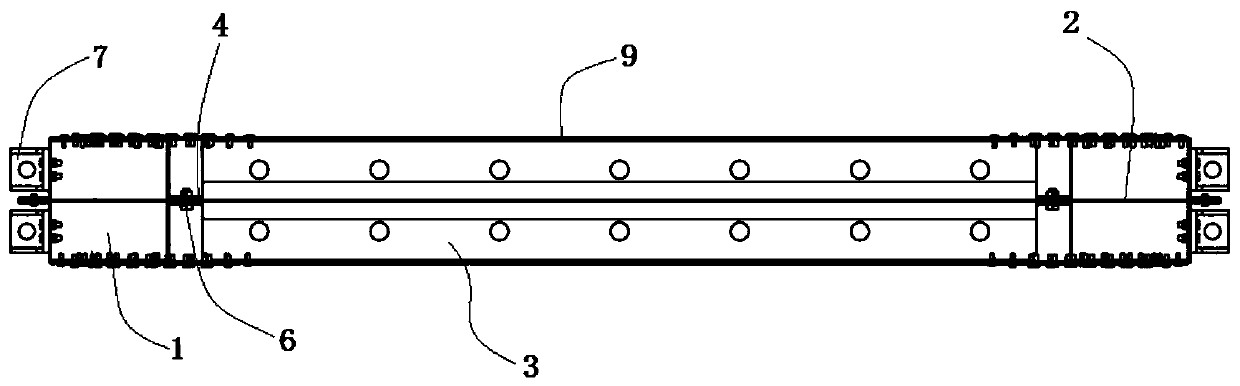

[0076] see figure 1 , this embodiment discloses a prefabricated steel plate shear wall system with two anti-seismic defense lines, including two-legged hat-shaped cold-formed thin-walled steel columns 1, embedded steel plates 2, cold-formed thin-walled steel beams 3 and Cable-stayed steel belt 9.

[0077] The hat-shaped cold-formed thin-walled steel column 1 composed of two limbs includes two outer crimped channel steels 101, see Figure 17 , is a schematic diagram of the outer crimped channel steel 101. The cold-formed thin-walled steel beam 3 includes two cold-formed thin-walled profiled steel 301, see Figure 20 , The section of cold-formed thin-walled special-shaped steel 301 is L-shaped.

[0078] see figure 2 , the embedded steel plate 2 is a rectangular plate arranged vertically, and each side of the embedded steel plate 2 is provided with two outer crimped channel steels 101 and two cold-formed thin-walled special-shaped steels 301, and the two sides of each side ...

Embodiment 2

[0094] see Figure 5 , this embodiment discloses a prefabricated steel plate shear wall system with two anti-seismic defense lines, including two-legged hat-shaped cold-formed thin-walled steel columns 1, embedded steel plates 2, cold-formed thin-walled steel beams 3 and Prefabricated decorative reinforced mortar board 10.

[0095] The hat-shaped cold-formed thin-walled steel column 1 composed of two limbs includes two outer crimped channel steels 101, see Figure 17 , is a schematic diagram of the outer crimped channel steel 101. The cold-formed thin-walled steel beam 3 includes two cold-formed thin-walled special-shaped steels 301, and the cross-section of the cold-formed thin-walled special-shaped steels 301 is L-shaped. see Figure 20 , is a schematic diagram of cold-formed thin-walled special-shaped steel.

[0096] see Image 6 , the embedded steel plate 2 is a rectangular plate arranged vertically, and each side of the embedded steel plate 2 is provided with two out...

Embodiment 3

[0111] see Figure 9 , this embodiment discloses a prefabricated steel plate shear wall system with two anti-seismic defense lines, including a cold-formed thin-walled steel column 11 with an extended end welded closed, an embedded steel plate 2, and a cold-formed thin-walled steel beam 3 And cable-stayed steel belt 9.

[0112] see Figure 18 Or 19, the cold-formed thin-walled thin-walled steel columns 11 with extended ends welded and closed include square steel columns 1101 and welded steel plates 1102, two square steel columns 1101 are arranged at intervals, and each square steel column 1101 faces the other square steel column 1101 The side walls of each are connected with welded steel plates 1102, and the two welded steel plates 1102 are on the same vertical plane.

[0113] see Figure 10 , there is a vertically arranged embedded steel plate 2 between the two square steel columns 1101, the embedded steel plate 2 is a rectangular plate, and the embedded steel plate 2 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com