Soft rock tunnel cantilever type heading machine excavation construction method

A cantilever roadheader and construction method technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problem of less rock formations, achieve the effects of reducing disturbance, avoiding damage, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A method for excavating a soft rock tunnel with a cantilever type roadheader, comprising the following steps:

[0036] Step 1: The cantilever roadheader, the second transport machine, the laser pointing device and the ventilator equipment enter the site, clean the surface of the site, and initially position the laser pointing device;

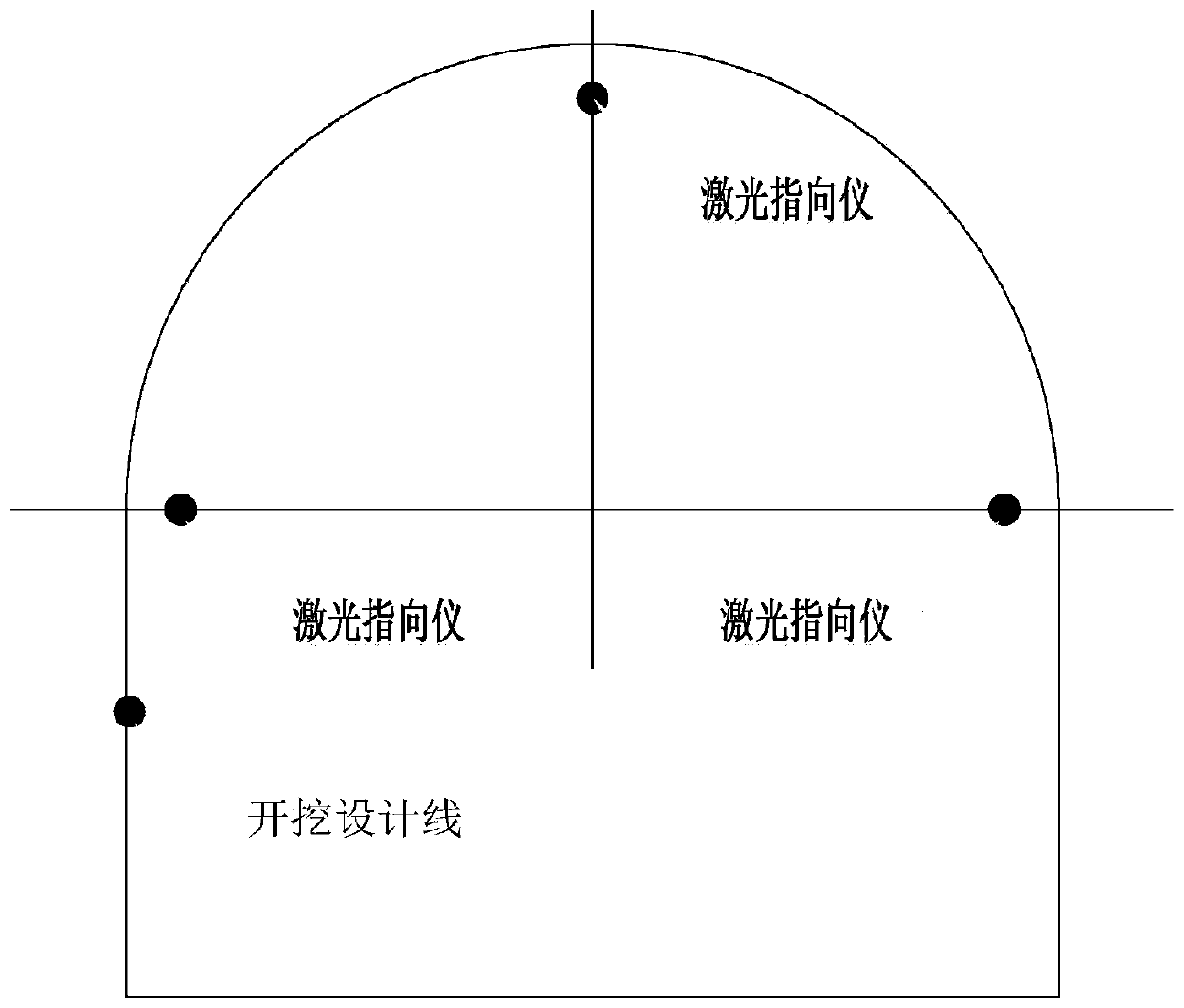

[0037] Step 2: Calculate the position of the laser center line according to the tunnel excavation design line, and install the laser pointing device according to the position of the laser center line;

[0038] Step 3: Laser pointing measurement and positioning: After the laser pointing device is installed and fixed firmly, use the measuring instrument to measure the position and direction of the laser center line of the laser pointing device;

[0039] Step 4: Carry out the positioning and commissioning of the cantilever roadheader and the second transporter;

[0040] Step 5: Excavation for the first time: Use the cutting head of the cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com