Chicken essence factory waste gas treatment process and waste gas treatment system

A technology for waste gas treatment and waste gas, which is applied in the field of waste gas treatment process and waste gas treatment system of chicken essence factory, can solve the problems of human discomfort, peculiar smell in the volatilization of essence and fragrance, which is difficult to effectively remove and uncomfortable, and achieves the effect of easier removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

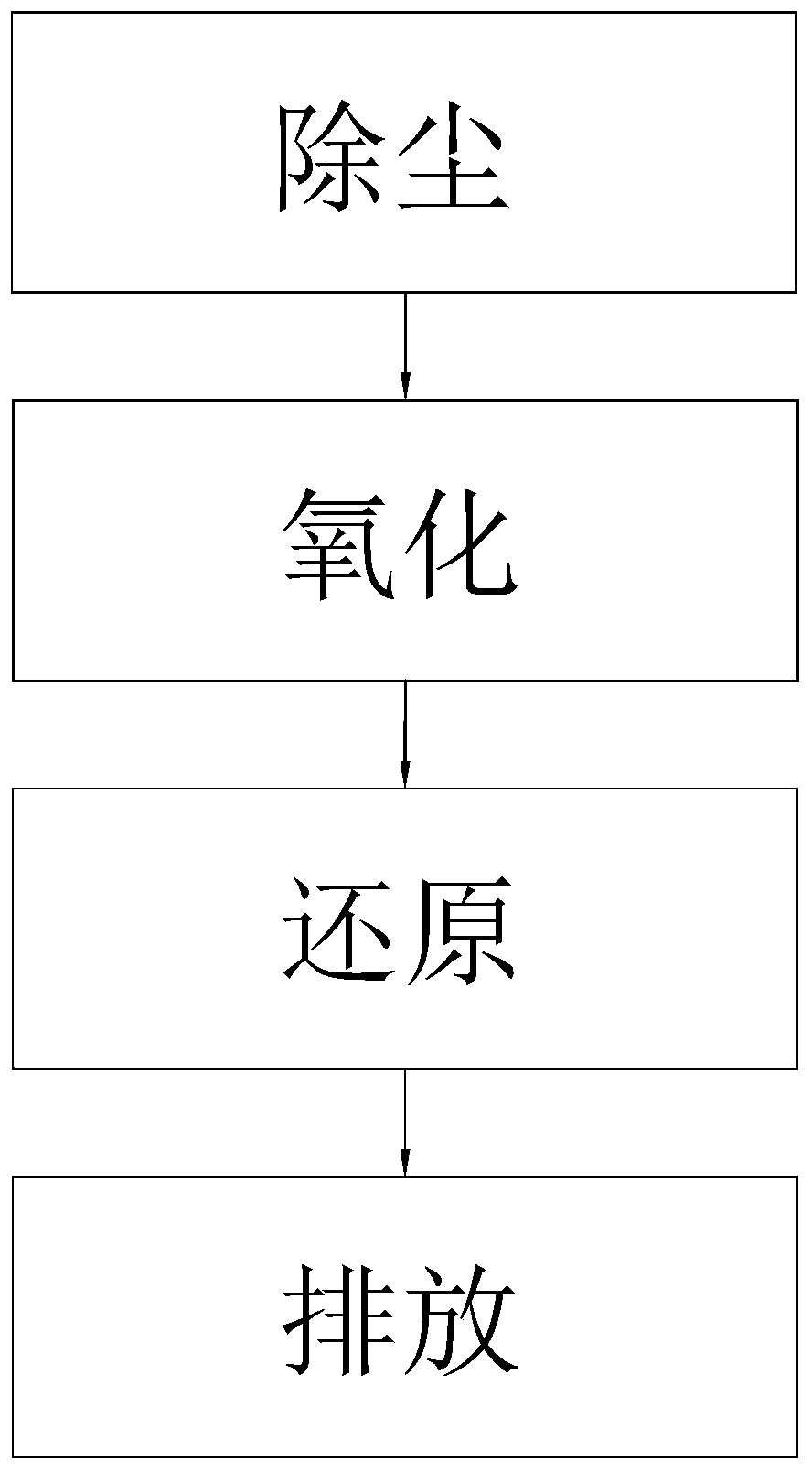

[0036] Embodiment 1: as figure 1 Shown, be a kind of chicken bouillon plant waste gas treatment process disclosed by the present invention, comprise the following steps:

[0037] S1: Dust removal, the waste gas discharged from the fluidized bed is passed into the cyclone dust collector 1, and the cyclone dust collector 1 filters the dust in the discharged waste gas,

[0038] When the temperature of the exhaust gas discharged from the fluidized bed is lower than 50 degrees Celsius, the exhaust gas treated by the cyclone dust collector 1 is passed into the dry filter, and the 3D filter in the dry filter is used to perform secondary dust removal on the exhaust gas;

[0039] When the temperature of the exhaust gas discharged from the fluidized bed is between 50 degrees Celsius and 60 degrees Celsius, the exhaust gas treated by the cyclone dust collector 1 is directly passed into the scrubber 6, and the temperature of the exhaust gas is reduced to below 50 degrees Celsius by the sc...

Embodiment 2

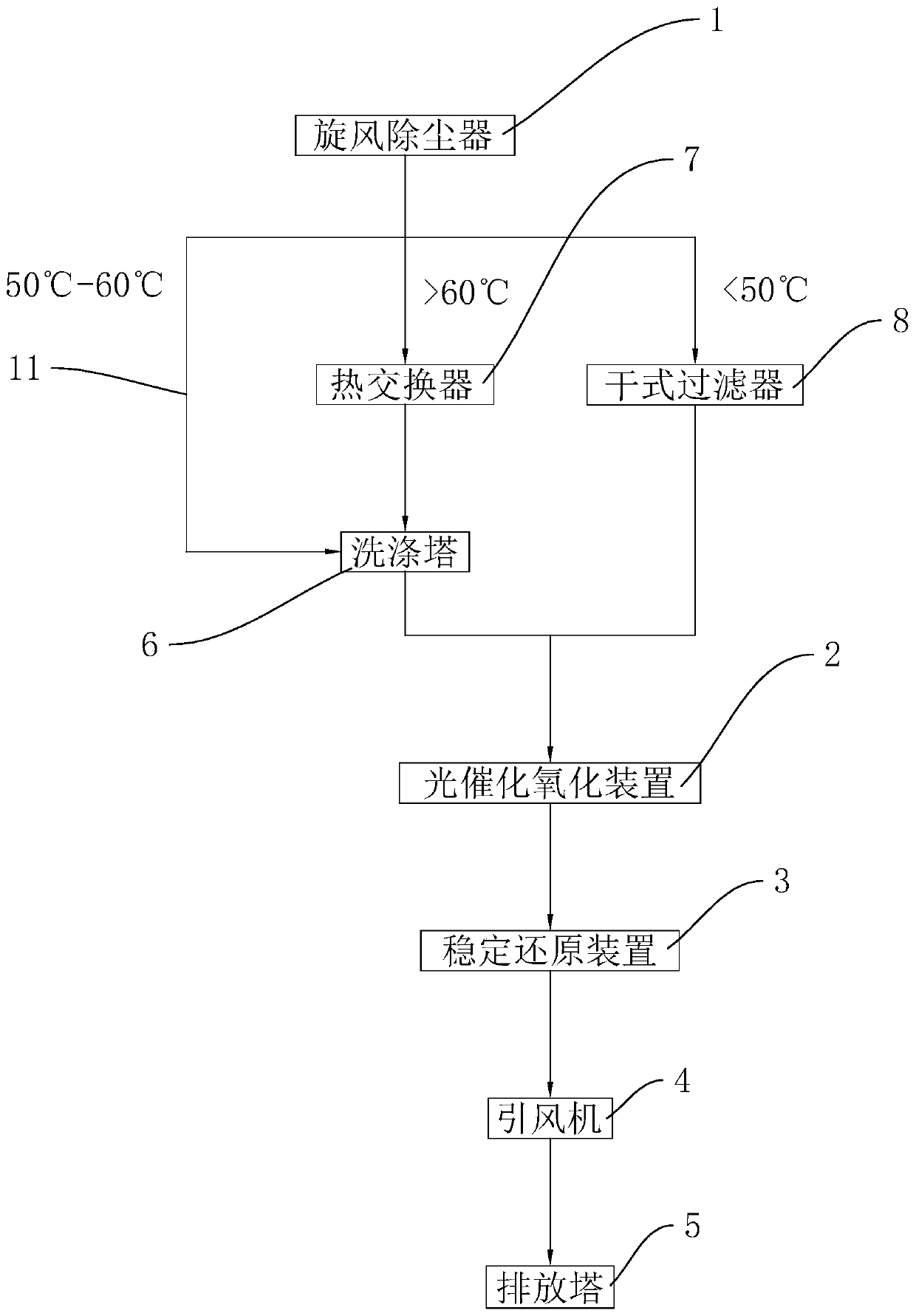

[0046]Embodiment 2: as figure 2 As shown, a waste gas treatment system of a chicken bouillon factory includes a cyclone dust collector 1 for initially filtering dust, a photocatalytic oxidation device 2 for oxidizing waste gas, a stable reduction device 3 for reducing waste gas, an induced draft fan 4 for driving the flow of waste gas and The discharge tower 5 for discharging waste gas, the cyclone dust collector 1, the photocatalytic oxidation device 2, the stable reduction device 3, the induced draft fan 4 and the discharge tower 5 are connected in sequence. The photocatalytic oxidation device 2 and the stable reduction device 3 are both equipped with a number of photocatalytic plates and ultraviolet lamps. The surface of the photocatalytic plates is attached with a nano-titanium dioxide catalyst, and the light emitted by the ultraviolet lamps is a vacuum wave. After the exhaust gas discharged from the fluidized bed is pre-filtered by the cyclone separator, the photocatalyt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap