A kind of PEF heat-shrinkable film and preparation method thereof

A heat-shrinkable film and film layer technology, which is applied in the field of materials, can solve the problems of difficult heat-shrinkable film recycling, unstable film bubbles, and difficulty in grasping, etc., and achieve good development prospects, good heat shrinkage rate, and the effect of promoting recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

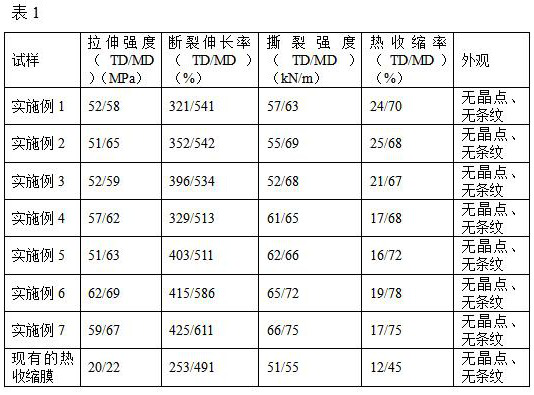

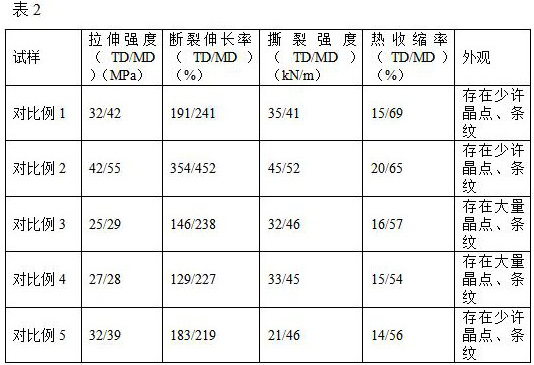

Examples

preparation example Construction

[0026] In the embodiment of the present invention, the preparation method of the modified fumed silica includes: after the fumed silica is soaked in an acid solution under a heating condition, the pH value is adjusted to 6-8, and drying treatment is performed; The dry-treated fumed silica is placed under the vapor of tetramethyltetravinylcyclotetrasiloxane, and contacts and reacts in a fluidized bed to obtain modified fumed silica. Wherein, the acid solution can be a hydrochloric acid solution with a mass percentage of 5% to 25%, and the soaking time is not less than 2h, which is not specifically limited. The modified fumed silica used in the present invention can be uniformly dispersed in the system, so as to improve the binding ability of fumed silica and the system, which is beneficial for the modified fumed silica after standing to form a network structure, and can further improve the quality of the formed heat shrinkable film. Stability, mechanical properties, aging resis...

Embodiment 1

[0045] The raw materials are weighed according to the raw material formulation of the outer film layer, the middle film layer and the inner film layer as described below, wherein the outer film layer and the inner film layer are all made of the following raw materials in parts by weight: high pressure low density polyethylene 40 parts, 15 parts of high-density polyethylene, 10 parts of ethylene-vinyl acetate copolymer, 5 parts of urethane acrylate, 5 parts of modified clay, 4 parts of oleic acid amide and 2 parts of antioxidant 1010; the intermediate film layer is composed of Made from the following raw materials in parts by weight: 25 parts of high pressure low density polyethylene, 20 parts of high density polyethylene, 10 parts of ethylene-vinyl acetate copolymer, 2 parts of modified fumed silica, 4 parts of oleic acid amide and 1 part of antioxidant share. The above weighed raw materials of each film layer are respectively put into the high-speed kneader for high-speed kne...

Embodiment 2

[0047] The raw materials are weighed according to the raw material formulation of the outer film layer, the middle film layer and the inner film layer as described below, wherein the outer film layer and the inner film layer are all made of the following raw materials in parts by weight: high pressure low density polyethylene 45 parts, 18 parts of high-density polyethylene, 12 parts of ethylene-vinyl acetate copolymer, 7 parts of urethane acrylate, 7 parts of modified clay, 4 parts of oleic acid amide and 2 parts of antioxidant 1010; Made from the following raw materials in parts by weight: 28 parts of high pressure low density polyethylene, 23 parts of high density polyethylene, 12 parts of ethylene-vinyl acetate copolymer, 3 parts of modified fumed silica, 4 parts of oleic acid amide and 1 part of antioxidant share. The above weighed raw materials of each film layer are respectively put into the high-speed kneader for high-speed kneading, fully mixed, and then added to the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com