Preparation method of energy-saving glass

A technology of energy-saving glass and molten glass, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of reducing actual service life, instability, negative impact of commercial application, etc., and achieve good energy saving effect and strong stability Sexuality, effect suitable for promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a preparation method of energy-saving glass includes the following steps:

[0044] a. Calculated according to the weight percentage of the raw materials, the proportions of the ingredients of each raw material are as follows:

[0045] Cesium tungsten bronze (Cs 0.3 WO 3 ): 7.77%; tungstic acid (H 2 WO 4 ): 9.85%; boric acid (H 3 BO 3 ): 49.10%; silicon dioxide (SiO 2 ): 20.79%; sodium fluoride (NaF): 11.81%; antimony trioxide (Sb 2 O 3 ): 0.67%;

[0046] Take each raw material component according to the formula, pulverize each raw material and pass through a 200-400 mesh sieve, and then fully mix the raw materials for 20-60 minutes to obtain mixed raw materials;

[0047] b. Pour the mixed raw materials obtained in the step a into the crucible, put the crucible into the atmosphere furnace, fill the non-oxidizing gas of the melting process into the atmosphere furnace to not less than 1.3 bar, and remove the atmosphere furnace air and water va...

Embodiment 2

[0052] This embodiment is basically the same as the first embodiment, and the special features are:

[0053] In this embodiment, a preparation method of energy-saving glass includes the following steps:

[0054] a. This step is the same as the first embodiment;

[0055] b. This step is the same as that of Embodiment 1;

[0056] c. this step is identical with embodiment one;

[0057] d. Homogenize the temperature of the molten glass obtained in step c, and cool it to 1100° C., and quench the molten glass to form;

[0058] e. This step is the same as the first embodiment.

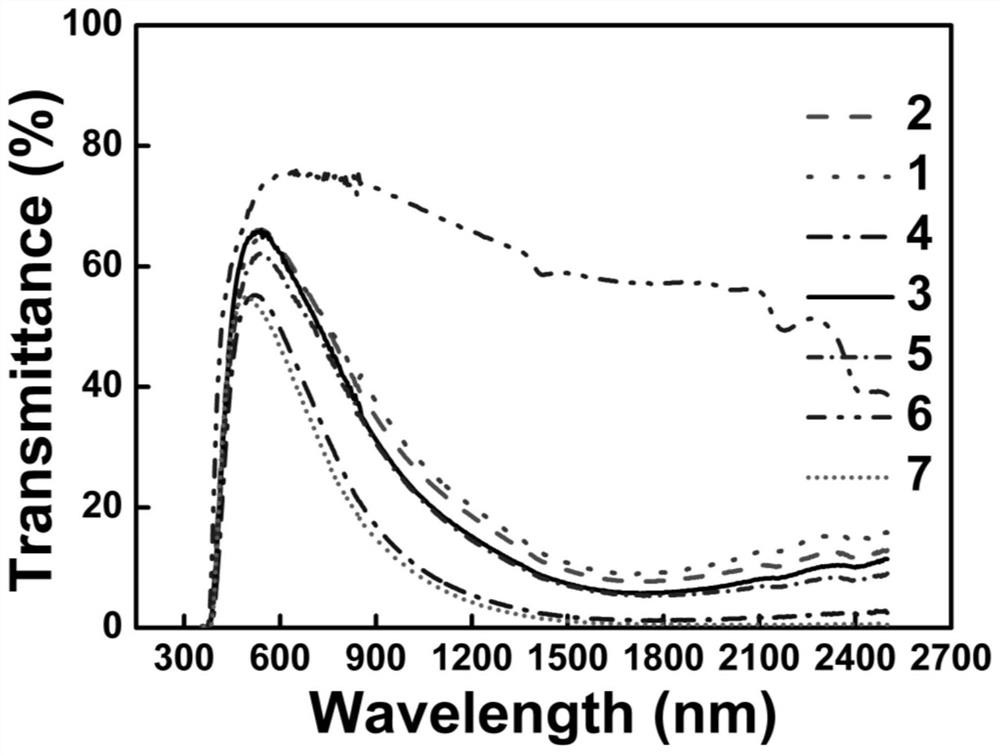

[0059] The energy-saving glass prepared in this example is subjected to experimental test analysis, see Table 1 and figure 1 .

Embodiment 3

[0061] This embodiment is basically the same as the previous embodiment, and the special features are:

[0062] In this embodiment, a preparation method of energy-saving glass includes the following steps:

[0063] a. This step is the same as the first embodiment;

[0064] b. This step is the same as that of Embodiment 1;

[0065] c. this step is identical with embodiment one;

[0066] d. Homogenize the temperature of the molten glass obtained in step c, and cool it to 1050° C., and quench the molten glass to form;

[0067] e. This step is the same as the first embodiment.

[0068] The energy-saving glass prepared in this example is subjected to experimental test analysis, see Table 1 and figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com