A kind of wear-resistant and high-temperature resistant lubricating grease and its preparation method and application

A high temperature resistant grease and grease technology, applied in the field of grease, can solve the problems of reduced service life, increased wear, serious grease rejection, etc., and achieves the effects of small water loss, good extreme pressure performance, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

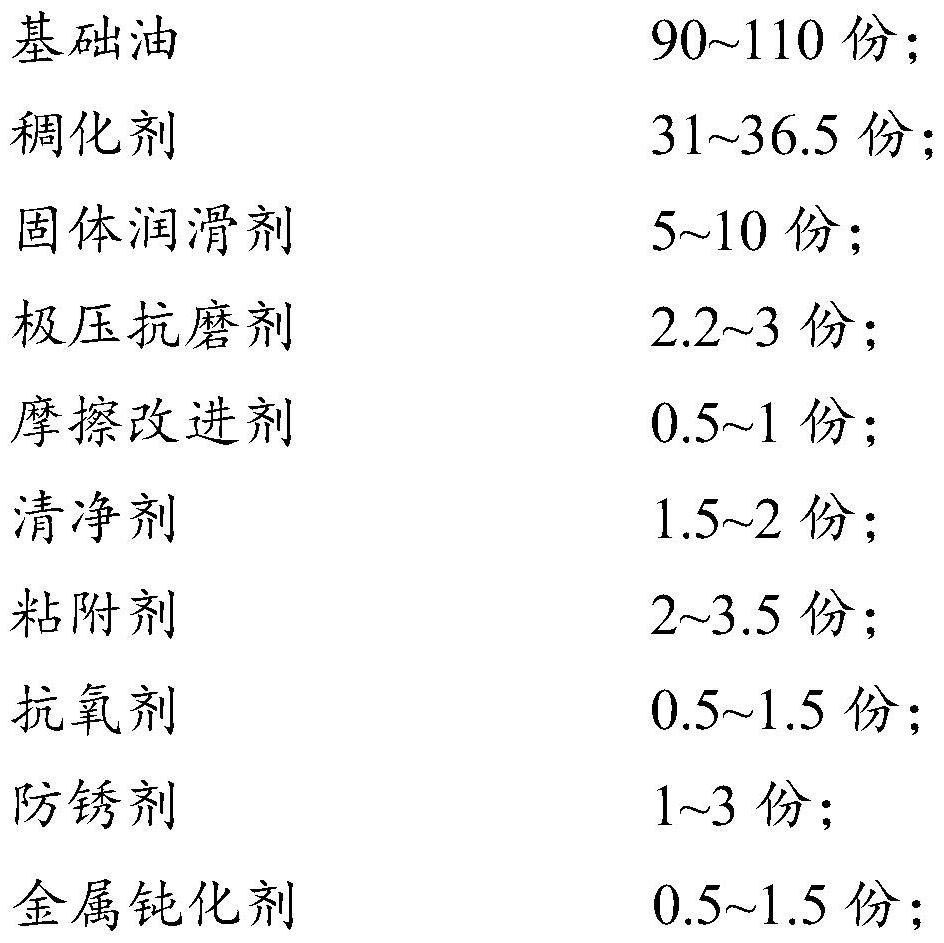

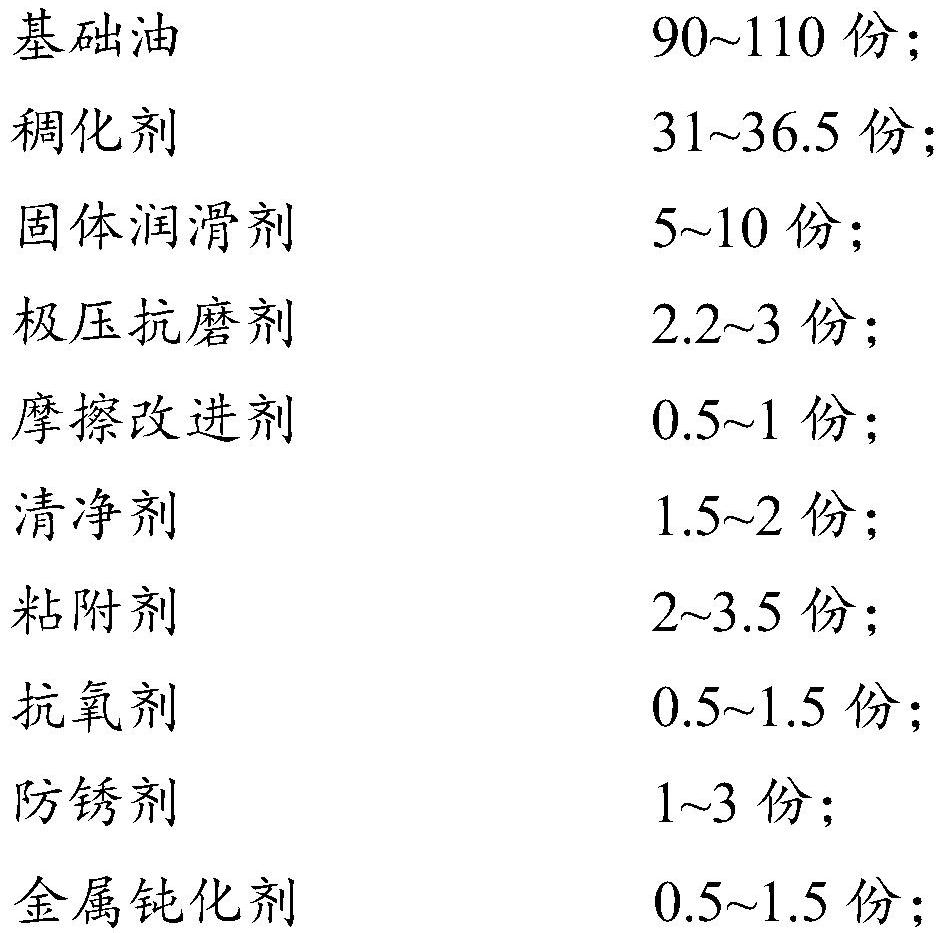

Method used

Image

Examples

preparation example Construction

[0027] In the present invention, the preparation method of the three-component complex lithium-based soap preferably includes the following steps: under airtight conditions, after heating and mixing 12-hydroxystearic acid, sebacic acid, boric acid and lithium hydroxide in water, It is heated and pressurized to obtain a thickening agent. In the present invention, the temperature of the heating and mixing is preferably 80-90°C, the temperature of the heating and pressurizing is preferably 150-155°C, the pressure is preferably 0.42-0.45MPa, and the time is preferably 2-3h.

[0028] In the present invention, based on the mass parts of the base oil, the raw materials for preparing the lubricating grease include 5-10 mass parts of a solid lubricant, and the solid lubricant is preferably a mixture of graphite fine powder and molybdenum disulfide fine powder. The particle size of the graphite fine powder is preferably 100-300 mesh; the particle size of the molybdenum disulfide fine po...

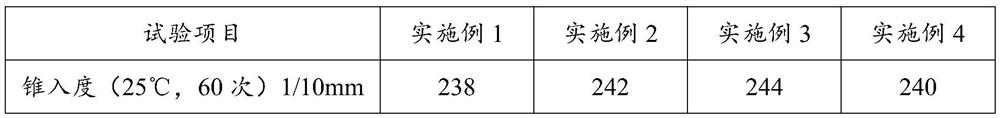

Embodiment 1

[0052] Fill 95 parts of base oil into the saponification kettle and heat to 60°C, put in 3.2 parts of pulverized adhesive (hydrogenated styrene-isoprene copolymer) and 1.7 parts of high base number synthetic calcium sulfonate; heat to 80°C , put in 19 parts of 12-hydroxystearic acid, heated to 85 ℃, put in 6.0 parts of sebacic acid and 1.2 parts of boric acid, heated to 90 ℃, put in 6.4 parts of lithium hydroxide monohydrate, cover and heat up, 155 ℃ constant temperature for 2.5 hours , the pressure is maintained at 0.42MPa; after pressure relief, continue to heat up to 170 ° C, add 6 parts of base oil, continue to heat up to 220 ° C, transfer to the blending kettle, carry out cyclic shearing, add antioxidant (alkylated phenylnaphthalene) amine) 1.0 parts, metal passivator 0.8 parts, rust inhibitor (octyl deimidazole) 1.8 parts, friction modifier 0.7 parts, extreme pressure anti-wear agent 2.4 parts and solid lubricant 7 parts, homogeneous, degassed, Obtain wear-resistant and ...

Embodiment 2

[0058] Fill 98 parts of base oil into a saponification kettle and heat to 60°C, add 3.0 parts of pulverized hydrogenated styrene-isoprene copolymer and 1.8 parts of high base number synthetic calcium sulfonate; heat to 80°C, add 12-hydroxyl 20 parts of stearic acid; heated to 85 ℃, put in 5.9 parts of sebacic acid and 1.3 parts of boric acid; heated to 90 ℃, put in 6.5 parts of lithium hydroxide monohydrate, cover and heat up; 150 ℃ constant temperature for 2.5 hours, the pressure is maintained at 0.43 MPa; after pressure relief, continue to heat up to 170 ° C, add 6 parts of base oil, continue to heat up to 220 ° C, transfer to the blending kettle; carry out cyclic shearing, add 1.1 parts of antioxidant (alkylated phenylnaphthylamine), 1.0 parts of metal passivator, 1.40 parts of rust inhibitor (octyl deimidazole), 0.8 parts of friction modifier, 2.6 parts of extreme pressure anti-wear agent and 8 parts of solid lubricant, homogenized and degassed;

[0059] The base oil is HV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com