High-electrochemical-activity specific surface fuel cell electrode as well as preparation and application thereof

A fuel cell electrode, electrochemical technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of small electrochemical active area of electrodes, high price, poor electrode performance, etc., to reduce catalyst load and reduce catalyst cost. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of the catalytic layer on the gas diffusion layer:

[0022] Place the gas diffusion layer at the base of the magnetron sputtering instrument, in an Ar gas atmosphere, with a gas flow rate of 6ml min -1 , power 30W, sputtering time 5min, substrate temperature 20°C, use Pt target material for sputtering, and obtain a catalytic layer with nanostructure;

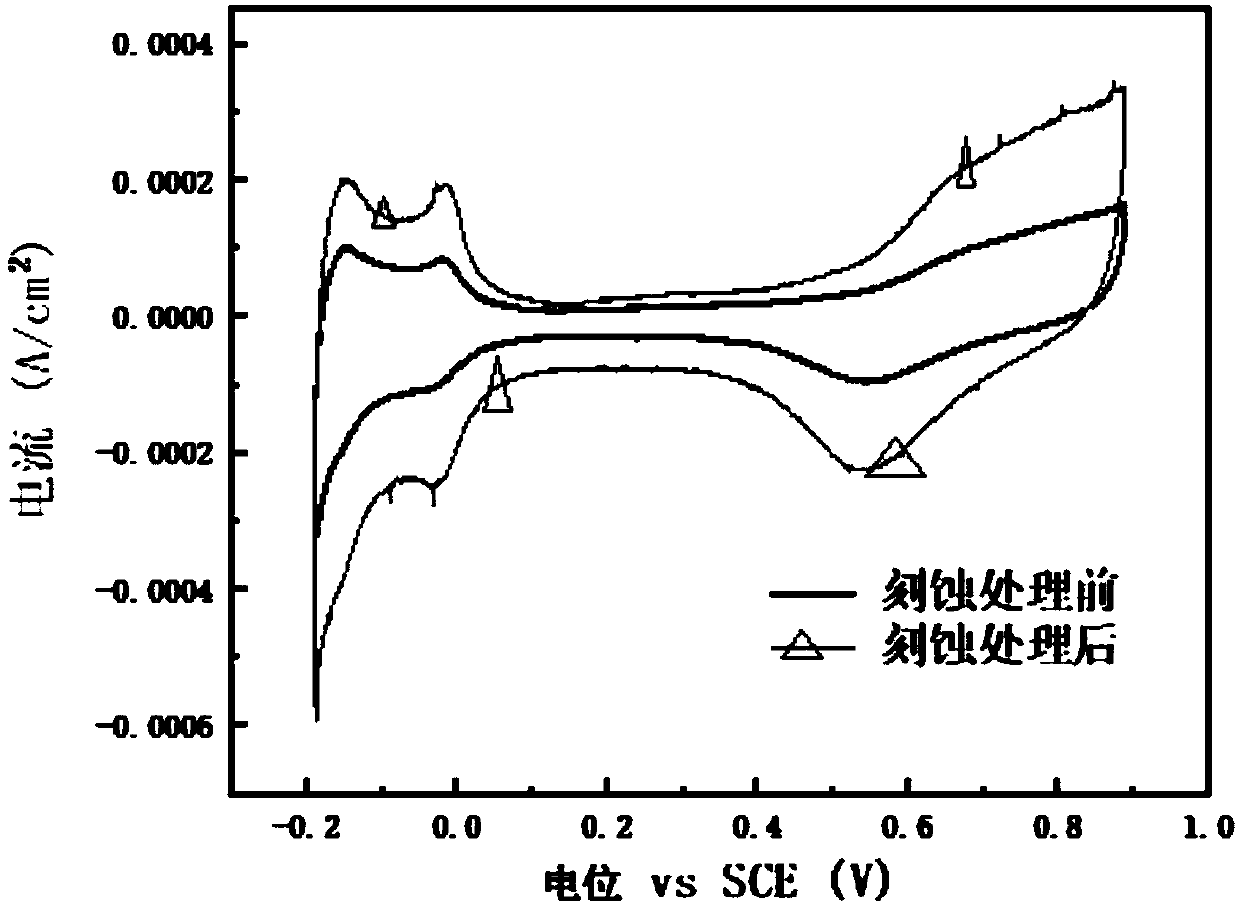

[0023] (2) Electrochemical etching treatment of the catalytic layer:

[0024] The gas diffusion layer loaded with platinum catalyst obtained in (1) was used as a working electrode to etch in a three-electrode system, and the electrolyte solution was 10mol L -1 Sodium perchlorate, the counter electrode is a platinum wire, the reference electrode is a saturated calomel electrode, the potential is -10V, and the etching time is 600s.

[0025] The electrochemically active area of the obtained samples was significantly improved.

Embodiment 2

[0027] The difference from the above-mentioned Example 1 is that the loading method of the catalytic layer is electrodeposition, and the gas diffusion layer is used as the working electrode, at 0.004mol L -1 Chloroplatinic acid and 0.5mol L -1 The mixed solution was deposited with a potential of -0.2V for 300s. Among them, the counter electrode is a platinum sheet, and the reference electrode is a saturated calomel electrode. The obtained sample was not significantly different from that in Example 1.

Embodiment 3

[0029] The difference from the above-mentioned Example 1 is that the electrochemical etching potential is -8V, and the electrochemically active area of the obtained sample is not significantly improved in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com