Electrolyte for lithium-air battery or lithium-copper battery

A lithium-air battery and electrolyte technology, which is applied to fuel cell type half cells and secondary battery type half cells, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problem of unsatisfactory cycle performance and power performance. Not ideal, polarization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (Preparation of Electrolyte)

[0043] The electrolyte solution for lithium-air batteries of the present invention can be prepared by the following production method.

[0044] That is, an electrolyte composed of a lithium salt is added to the above-mentioned organic solvent, stirred and confirmed to be completely dissolved, and an additive is added and stirred to be confirmed to be completely dissolved. The obtained electrolytic solution is dehydrated to reduce the water content in the electrolytic solution to 100 ppm or less, preferably 50 ppm or less, thereby obtaining the target electrolytic solution for lithium-air batteries. The electrolyte solution for lithium-air batteries of the present invention may have a viscosity at 25° C. of 20 cP or less.

[0045] By using the electrolyte solution for lithium-air batteries prepared in this way, lithium-air batteries can be produced, including button batteries, soft-pack batteries, hard-shell batteries, and the like. A lit...

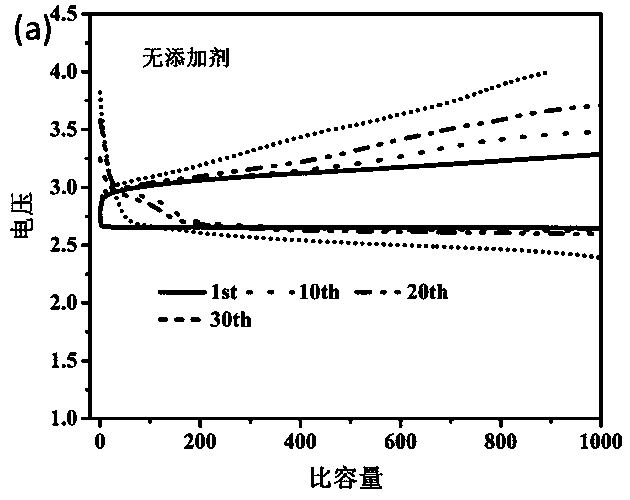

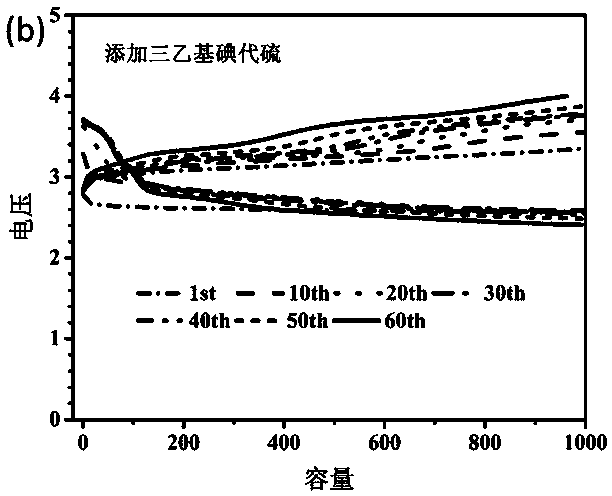

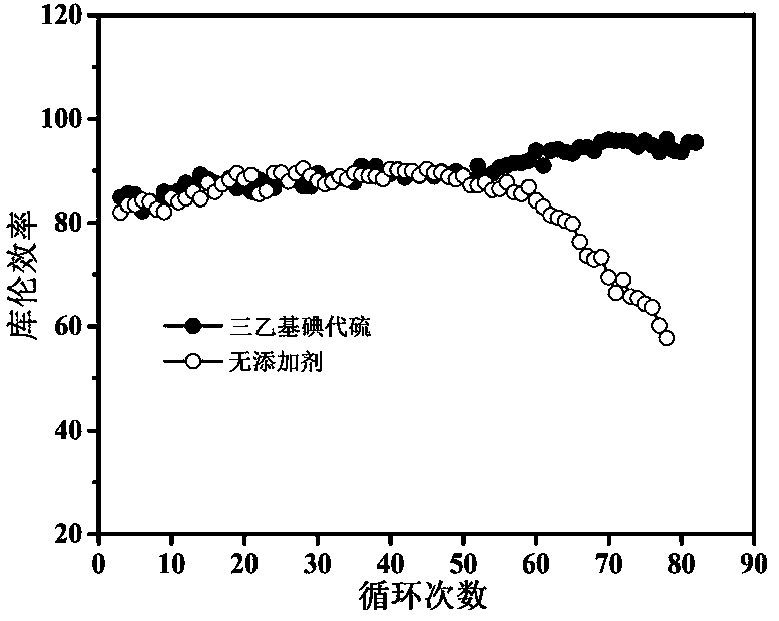

Embodiment 1

[0064] Preparation of basic electrolyte: The electrolyte is a mixed system of tetraethylene glycol dimethyl ether (water content 10ppm) and bistrifluoromethanesulfonimide lithium (water content 50ppm), and bis Lithium trifluoromethanesulfonyl imide is stirred and confirmed to be completely dissolved to obtain a basic electrolyte, wherein the lithium bistrifluoromethanesulfonyl imide is 1mol / L;

[0065] Preparation of electrolyte solution for lithium-air battery: In a glove box (moisture <0.1ppm, oxygen content <0.1ppm) filled with argon, add triethyliodosulfur (moisture content 10ppm) to the basic electrolyte solution, the addition amount is 0.05mol / L, the structural formula of the electrolyte additive is as follows:

[0066]

[0067]Assembled battery: the positive electrode active material of the lithium-air battery is carbon nanotubes coated on carbon paper, the negative electrode is a circular metal lithium sheet with a diameter of 12 mm, the battery case is 2032 type, t...

Embodiment 2

[0071] In a glove box (moisture < 0.1ppm, oxygen < 0.1ppm) filled with argon, add choline iodide to the electrolyte in an amount of 0.01mol / L. The structural formula of the electrolyte additive is as follows:

[0072]

[0073] A lithium-air battery is assembled with this electrolyte. Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com