Multi-surface treatment process for PCB

A PCB board and surface treatment technology, which is applied in the field of processing technology combining multiple surface treatments of PCB boards, can solve the problems that immersion silver does not have the physical strength of chemical nickel plating/immersion gold, loses luster, and surface treatment processes are difficult to achieve. , to achieve the effect of fast and efficient production process, strong tolerance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

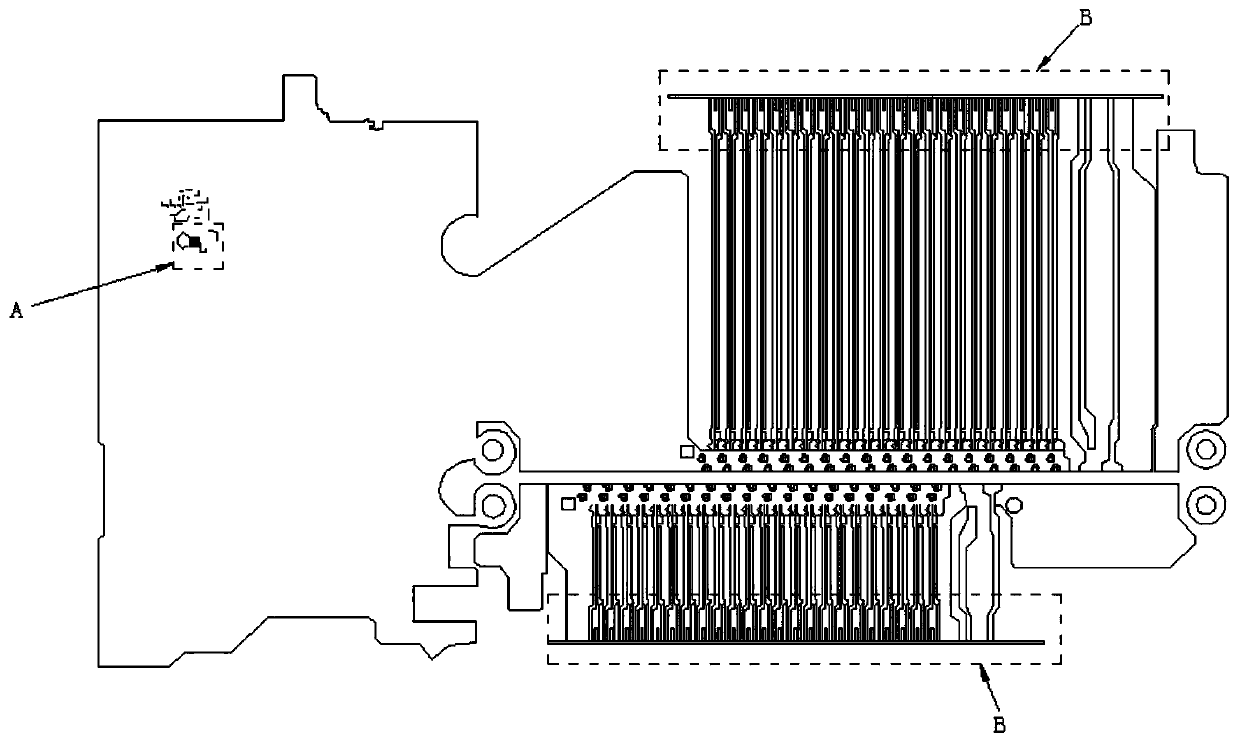

[0028] Such as figure 1 Shown is the PCB board to be surface treated in this embodiment, wherein the A area is the BGA area, which needs to be organically coated; the B area is the gold finger area, which needs to be electroplated with hard gold; the remaining areas need to be subjected to immersion gold treatment; The surface treatment process includes the following steps:

[0029] Step 1: Install a barrier film on the surface of the PCB board, the barrier film covers the non-copper-plated area on the surface of the PCB board, the barrier film is provided with a window, and the window covers the A area of the PCB board (ie, the BGA area) and is made into a printing screen;

[0030] Step 2: Use the screen plate made of the above-mentioned film to coat the BGA area of the PCB board with selective ink that resists immersion gold potion, and then perform drying treatment;

[0031] Step 3: Carry out immersion gold treatment on the PCB board;

[0032] Step 4: Cover the PCB bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com