Server cooling system combining server chip gravity type heat pipe and heat pipe back plate

A chip heat dissipation and heat dissipation system technology, which is applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of low energy efficiency utilization and high PUE value of data centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

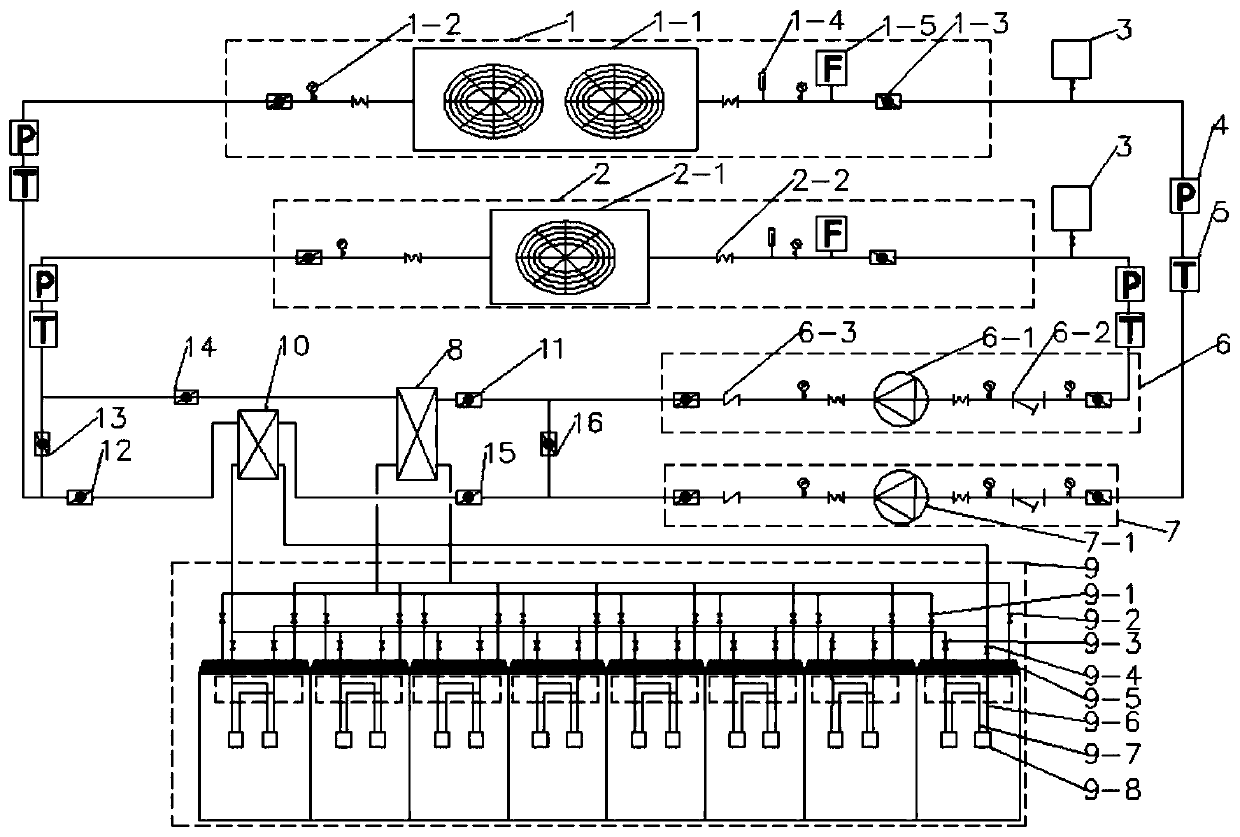

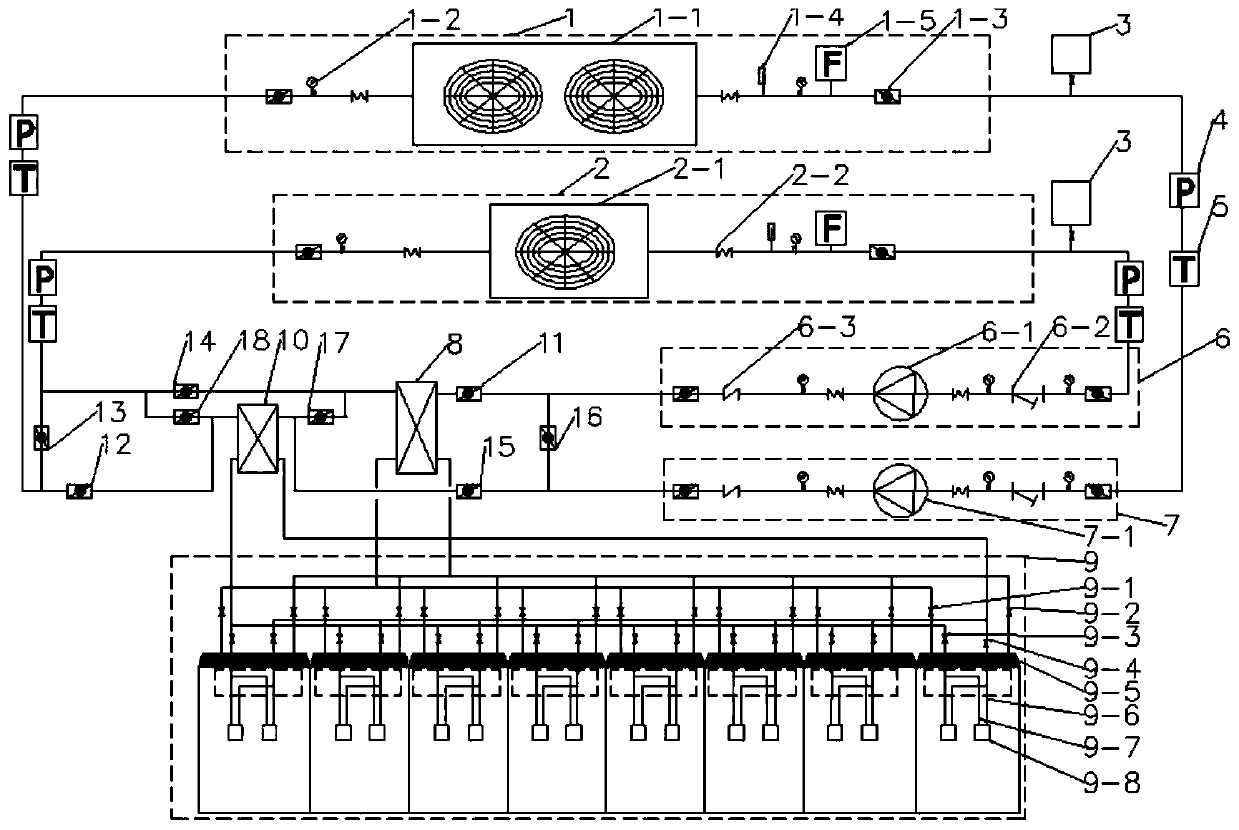

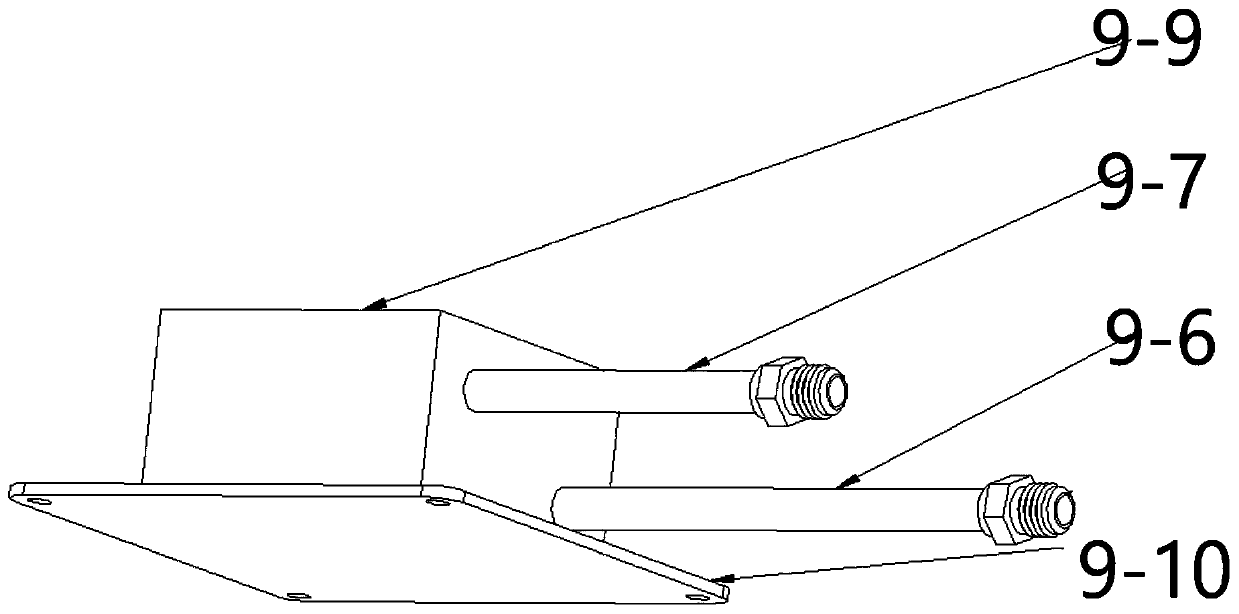

[0055] Such as figure 1 Shown is a schematic diagram of a server heat dissipation system combined with a server chip gravity heat pipe and a heat pipe backplane, including a mechanical refrigeration unit 2, a natural cooling unit 1, a system voltage stabilization unit 3, a pressure sensor 4, a temperature sensor 5, and a mechanical refrigeration pump unit 6 , natural cooling pump unit 7, heat pipe backplane cooling distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com