Matchbox with high durability

A matchbox and durability technology, applied in the field of matchboxes, can solve the problems of high consumption of raw materials, flowing phosphorus, and less scratching times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is described in further detail below with accompanying drawing as embodiment:

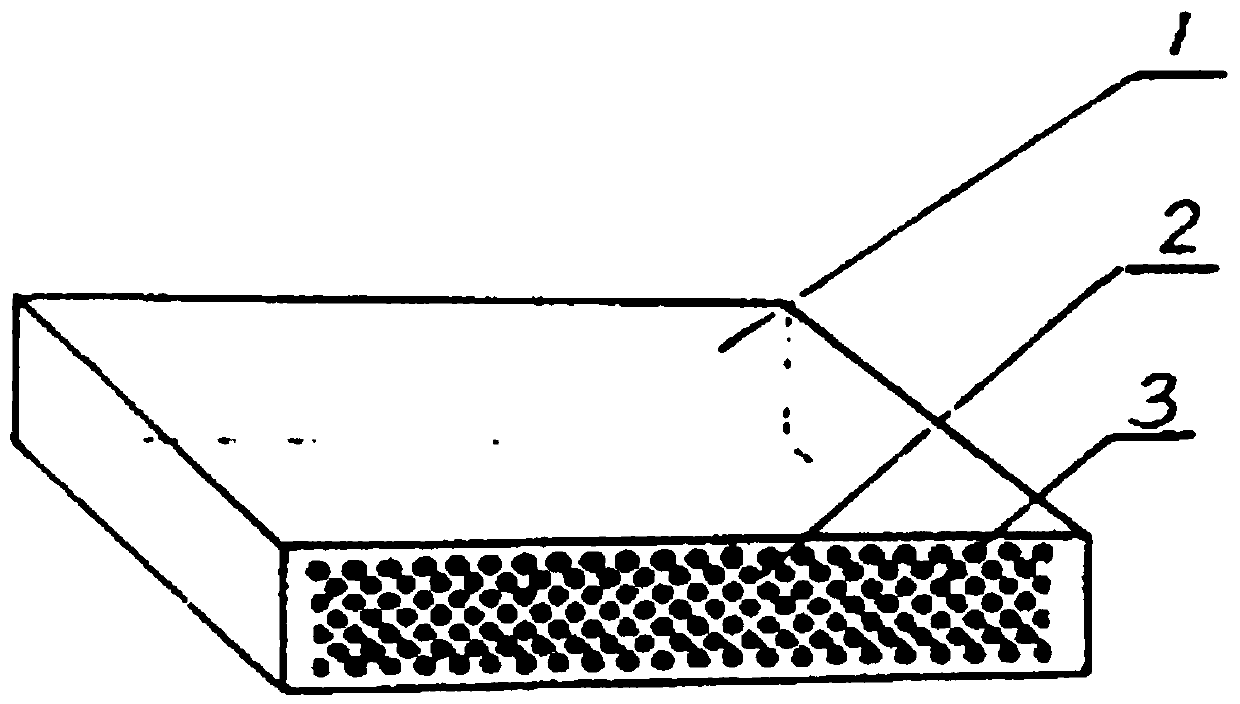

[0008] figure 1 Among them, a rectangular printed hard paper can be folded into a matchbox body 1, and the trademark and publicity pattern are generally printed. On the front, bottom and one side of the box body, the patterned scratch surface 2 is printed with phosphorous paste As a result, on the other side of the box body, the pattern-type scratch surface 2 is a dot pattern, and the dot-shaped protrusions 3 are a phosphor slurry surface, and the scratch surface where the protrusions are located is a two-layer structure that can be torn off.

[0009] The composition of the phosphorus slurry used is (weight %): red phosphorus 38-42; antimony trisulfide 30-34 sulfur powder 13-15; calcium carbonate 1-2; binder 8-12. The adhesive used is compounded from 108 glue, peach gum and white latex. The fineness of the medicine is 350-450 mesh. Due to the action of the adhesive an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com