Casting raw sand screening device

A screening device and raw sand technology, applied in the direction of casting molding equipment, manufacturing tools, cleaning/processing machinery of casting mold materials, etc., can solve the problem of easy blockage of screen holes, decrease of screening efficiency, influence of mold strength, casting surface quality, etc. problem, to achieve the effect of good fragmentation and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

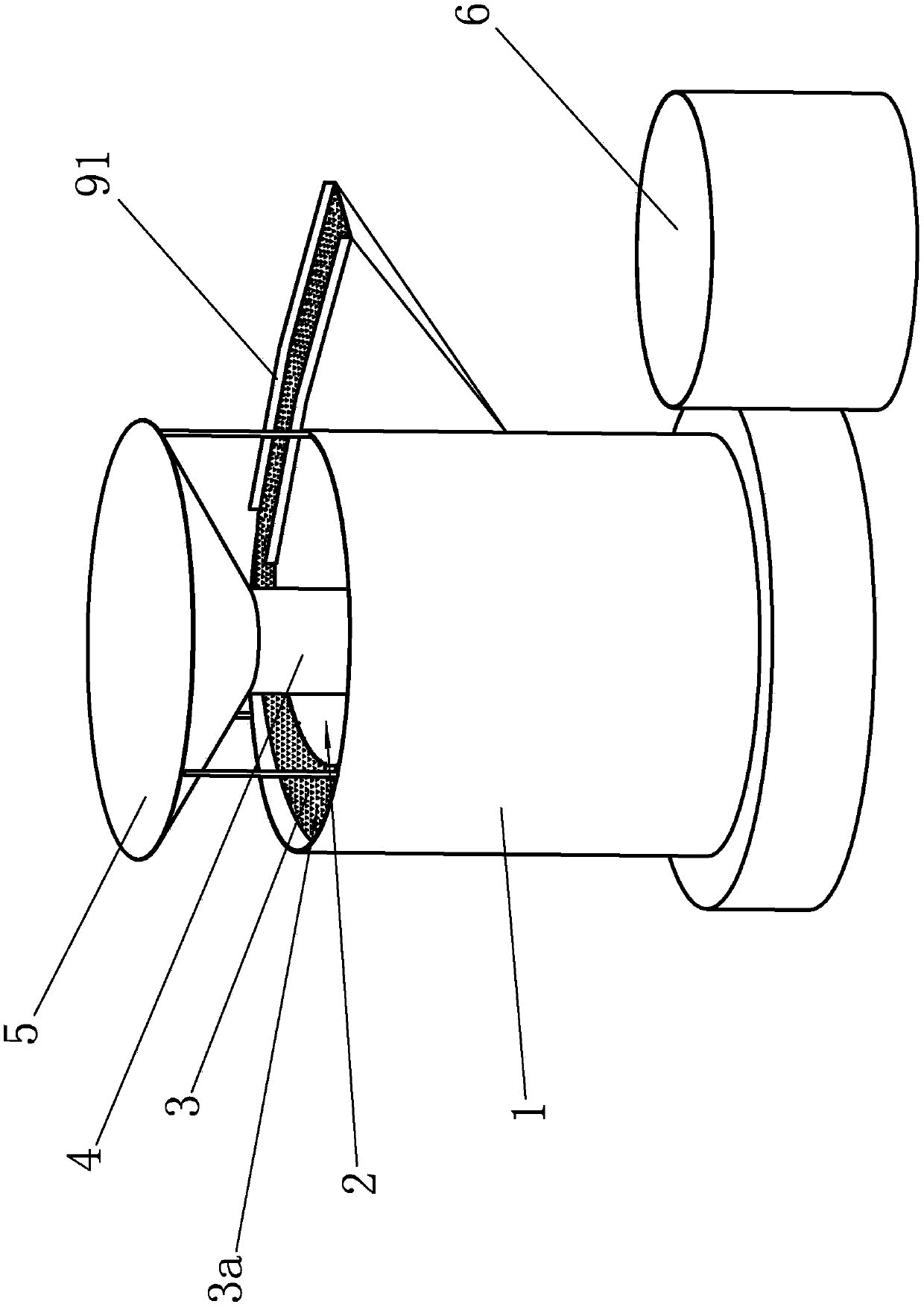

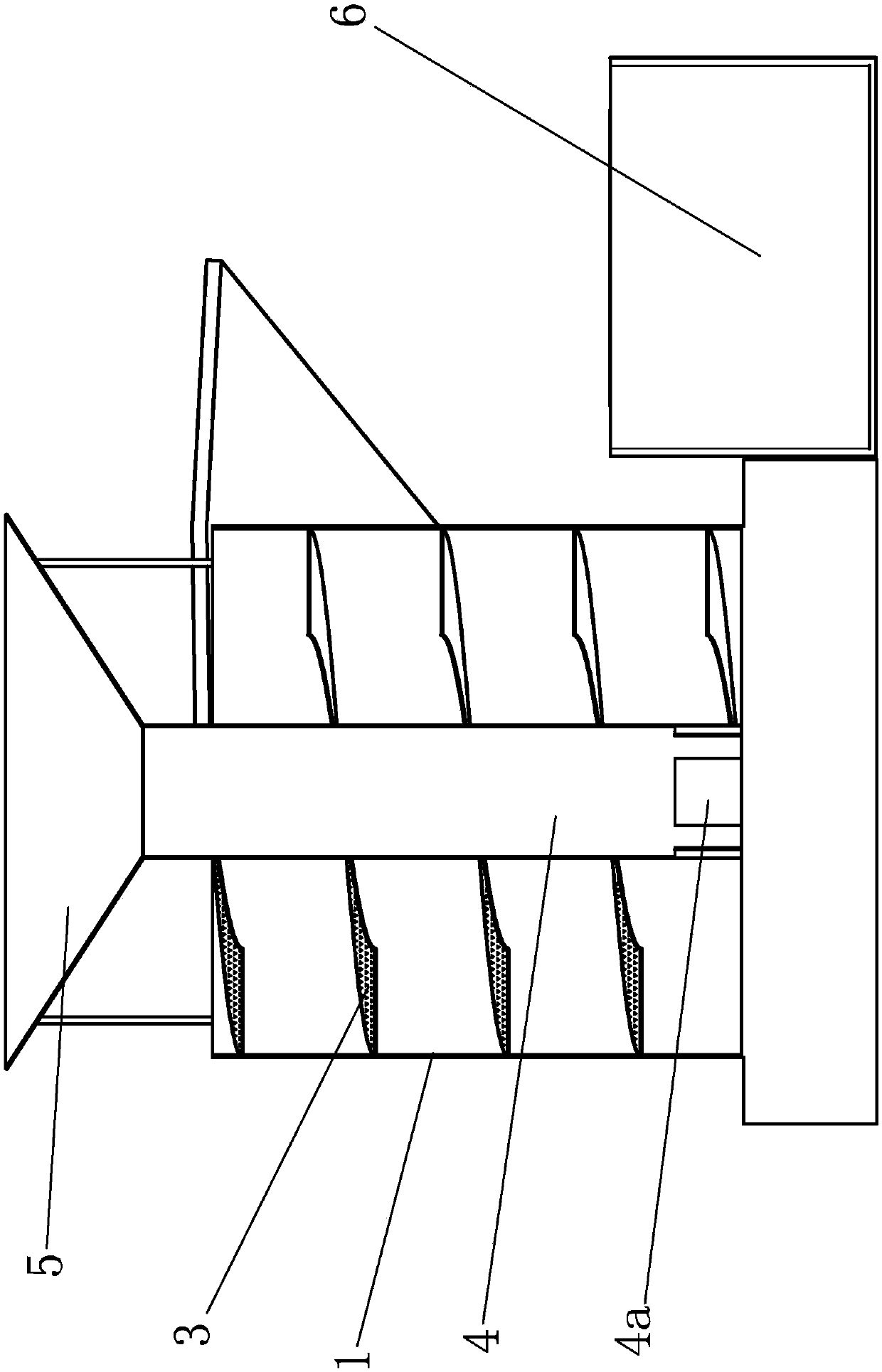

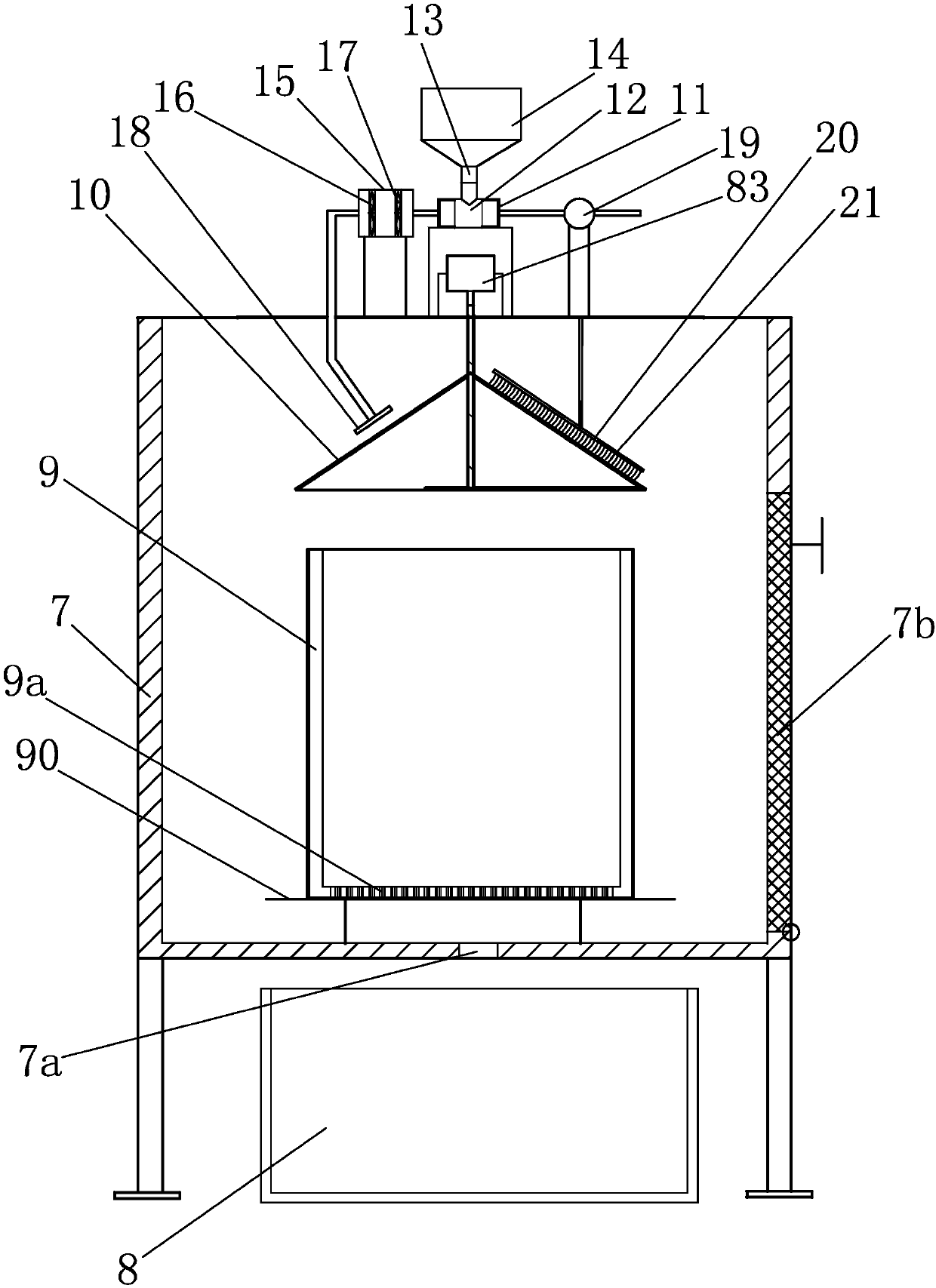

[0031] Such as figure 1 and figure 2 As shown, the sand crushing device includes a first vibrating plate, the first vibrating plate includes a first disc body 1 with a top opening, the first disc body 1 has a first material storage chamber 2, and the inner wall of the first disc body 1 is fixed with The first helical track 3 that spirals up, the top surface of the first helical track 3 is evenly distributed with some tapered protrusions 3a, such as Figure 14 As shown, the protruding portion 3a is conical, and the first spiral track 3 is made of sheet metal. The protruding portion 3a is integrally formed by die stamping. In this embodiment, the diameter of the bottom end of the conical protruding portion 3a is 3mm. , the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com