Casting technology for ensuring content of manganese in steel for nuclear power

A manganese content and high-tech technology, which is applied in the field of pouring to ensure the manganese content of steel for nuclear power, can solve problems such as loss, and achieve the effects of reducing power consumption per ton of steel, saving pouring costs, and shortening smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

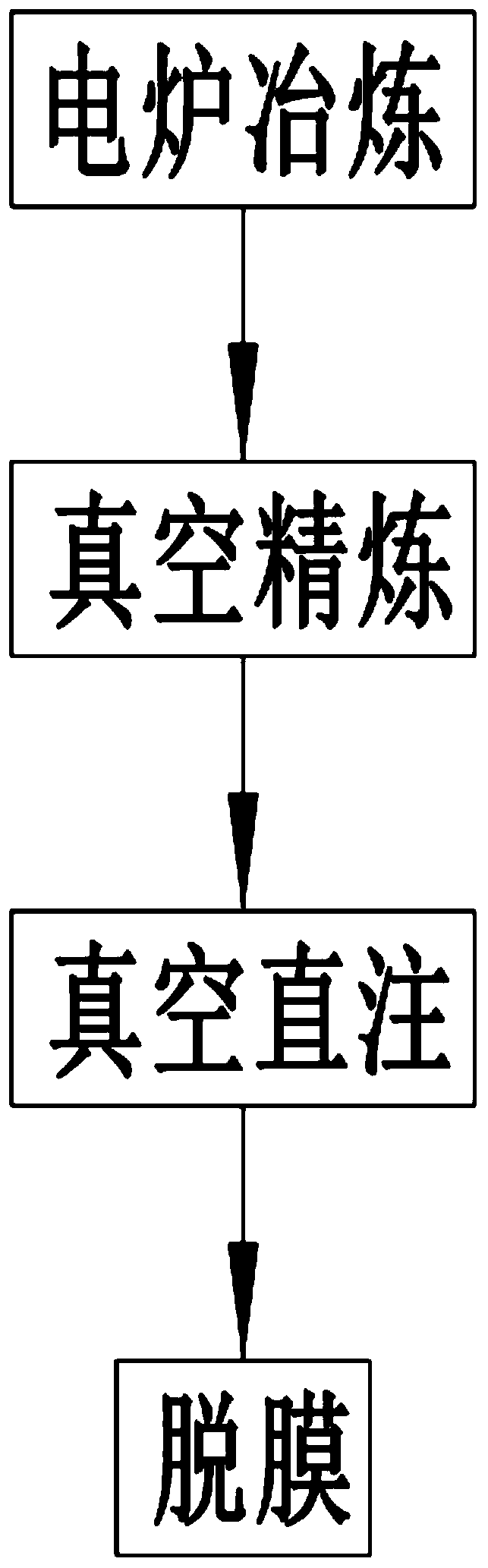

[0021] see figure 1 and figure 2 , a pouring technique for ensuring the manganese content of steel for nuclear power, comprising the following steps:

[0022] Step 1, electric furnace smelting: rough smelting of molten steel in an electric furnace to obtain raw material A whose composition temperature meets the process requirements;

[0023] Step 2. Vacuum refining: Input the raw material A into the refining furnace, adjust the chemical composition and temperature, and obtain the semi-finished product B;

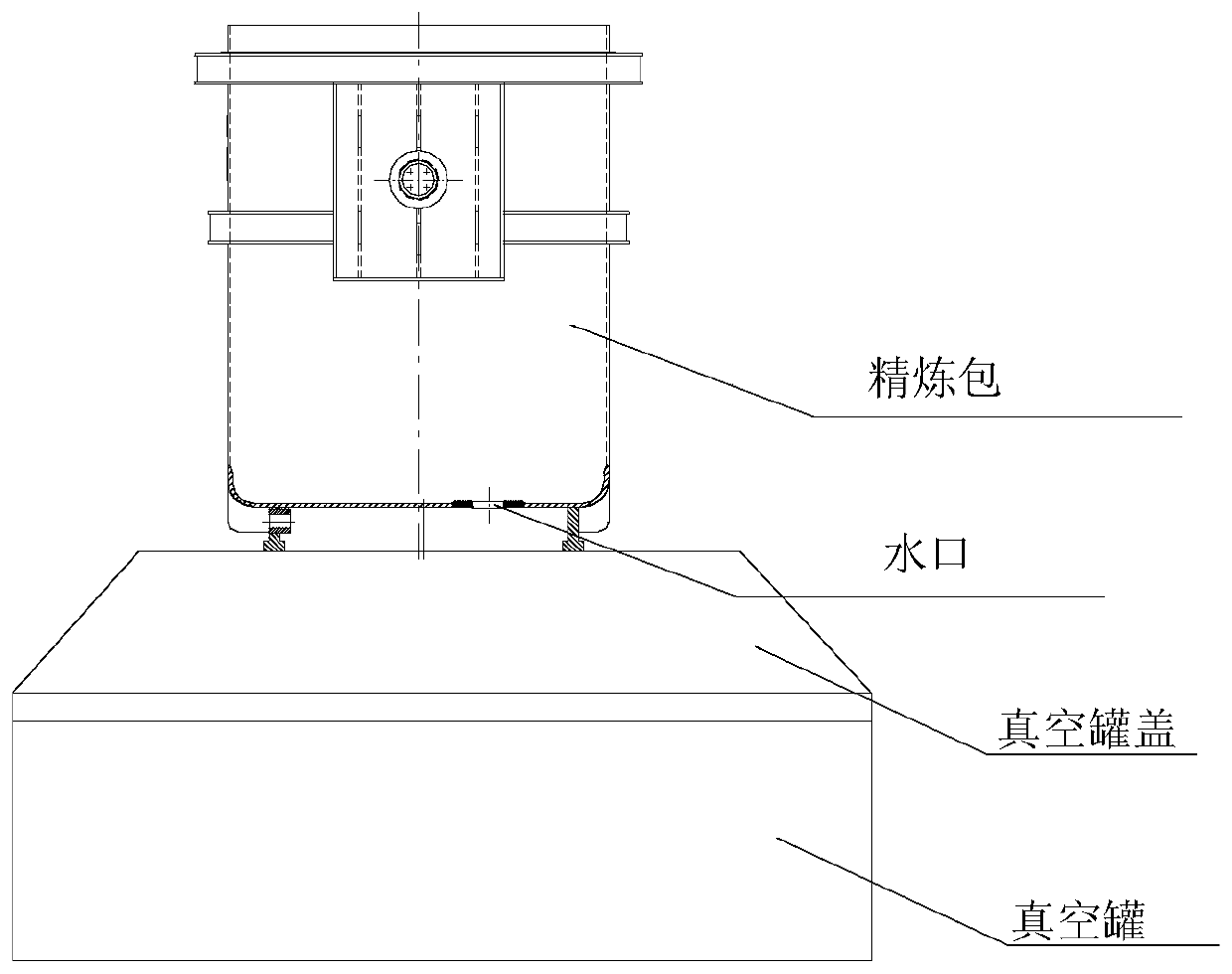

[0024] Step 3. Vacuum direct injection: The semi-finished product B is directly poured into the steel ingot mold in the vacuum tank through the argon protection injection flow, the refining package is directly seated on the pouring vacuum tank cover, and the argon protection injection flow is directly poured into the steel ingot mold in the vacuum tank Within 1 minute, the pouring is completed, the vacuum is broken, the first batch of heating agent is added within 1 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com