Environment-friendly graphene oxide mortar and preparation method thereof

A graphene and environmental-friendly technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems that the particle size range of graphene oxide is not easy to control, affects the mechanical properties and durability of mortar, and environmental pollution, etc. , to achieve the effect of eliminating ultrasonic dispersion equipment, reducing the preparation process links, and avoiding the risk of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

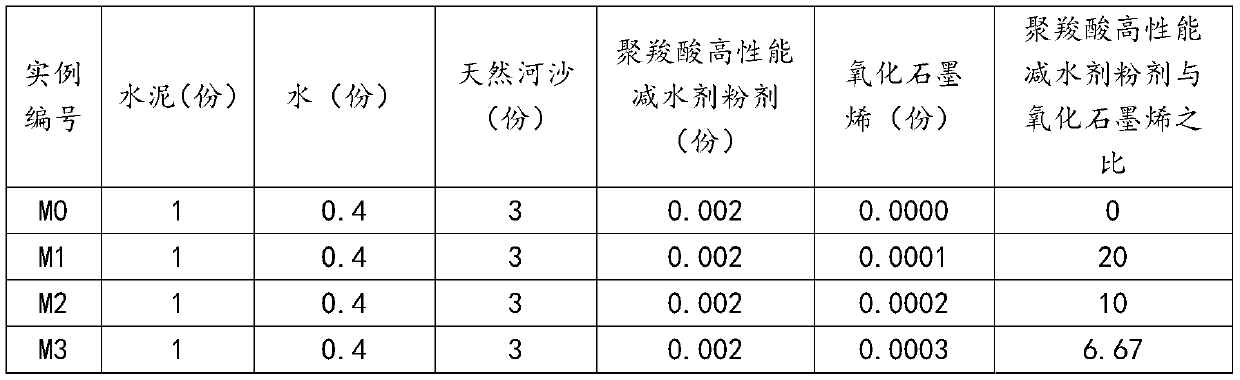

[0032] Example 1: Test of the influence of graphene oxide content on the compressive strength and flexural strength of mortar.

[0033] Examples of graphene oxide mortar and the ratio of raw materials are shown in Table 1.

[0034] Table 1

[0035]

[0036] The polycarboxylic acid high-performance water reducing agent powder in this embodiment is Sika VisCocrete-540. Other polycarboxylic acid high-performance water reducing agent powders with similar properties can also be used.

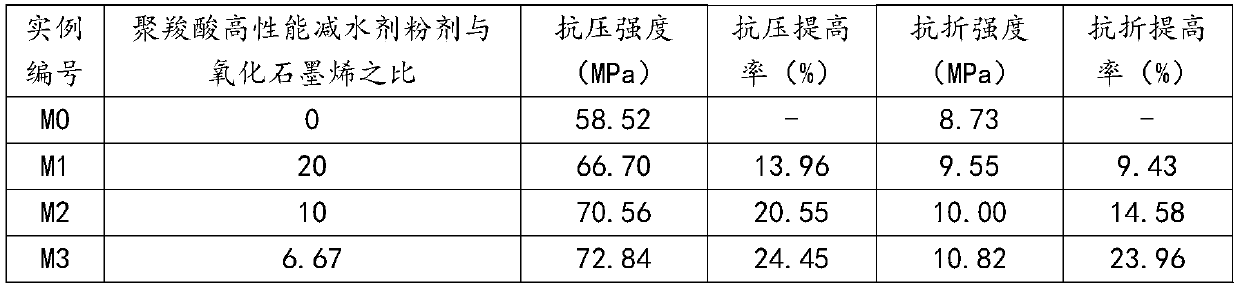

[0037] The 28-day compressive strength and flexural strength of the mortars numbered M0-M3 are shown in Table 2.

[0038] Table 2

[0039]

[0040] The results show that: for the cement-based environment, the graphene oxide is dispersively treated, and the 28-day compressive strength and flexural strength of the mortar under the optimized dosage and the ratio of graphene oxide and polycarboxylate high-performance water-reducing agent powder Both have been improved, as follows:

example M1

[0041] Example M1: The compressive strength of mortar increased from 58.52MPa (reference mortar) to 66.70MPa, an increase of 13.96%; the flexural strength increased from 8.73MPa (reference mortar) to 9.55MPa, an increase of 9.43%.

example M2

[0042] Example M2: The compressive strength of the mortar increased from 58.52MPa (reference mortar) to 70.56MPa, an increase of 20.55%; the flexural strength increased from 8.73MPa (reference mortar) to 9.55MPa, an increase of 14.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com