Organosilicon quaternary ammonium salt fabric finishing agent based on block silicone oil and preparation method thereof

A technology of organosilicon quaternary ammonium salt and fabric finishing agent, applied in fiber treatment, plant fiber, biochemical fiber treatment and other directions, can solve the problems of single performance and difficult synthesis, and achieve the effect of excellent antibacterial performance and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

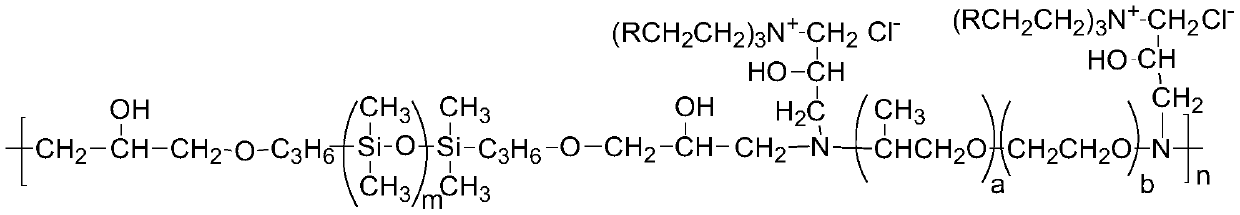

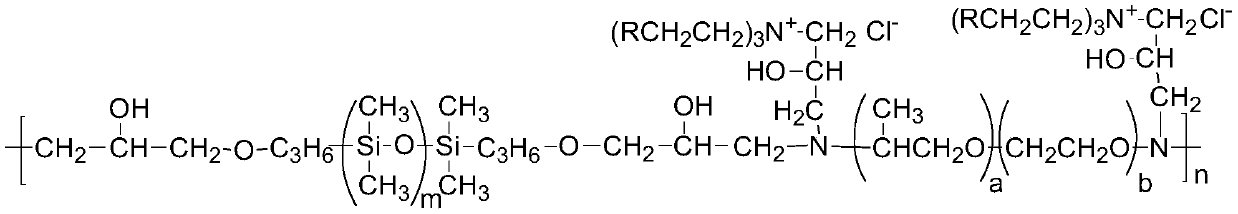

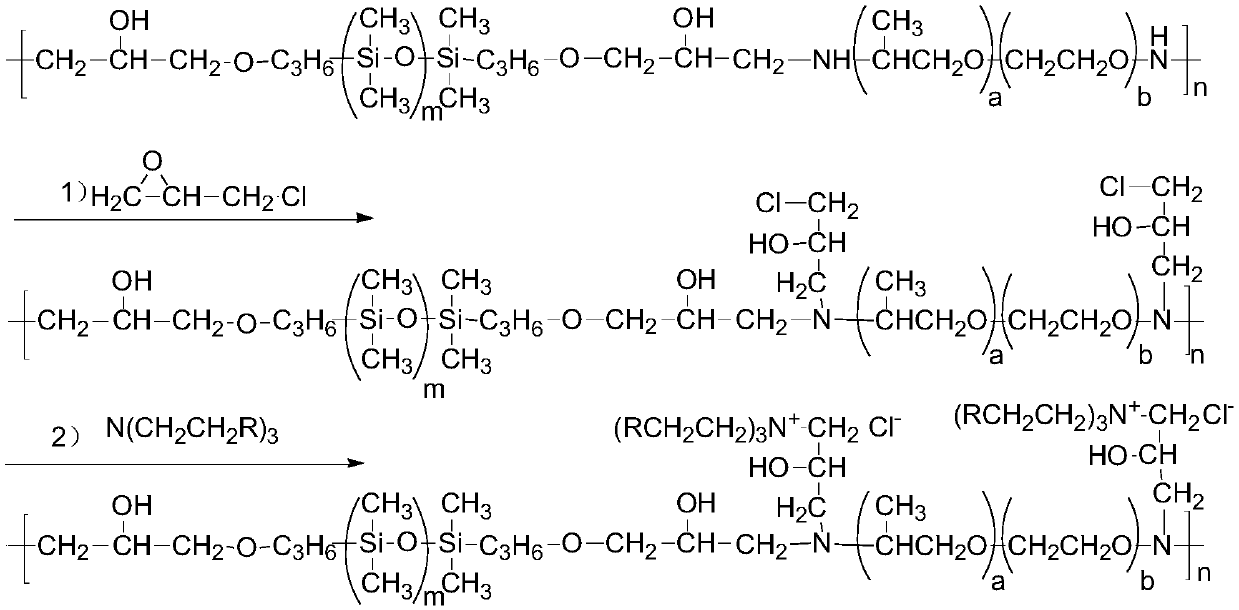

Image

Examples

Embodiment 1

[0024]

[0025] Take 30g of ternary block copolymerized silicone oil with a molecular weight of about 11000 and 0.3g of epichlorohydrin into a 100mL three-necked flask, stir and heat up to 105°C, after 1.0h of reaction, add 0.45g of triethanolamine into the bottle, and continue to Stir and react at 110°C for 2 hours. After the reaction is completed, the product organosilicon quaternary ammonium salt fabric finishing agent I is obtained.

[0026] Emulsification process: Take 30g of the product, pour it into a 250mL beaker, add 10 drops of acetic acid first, then slowly add 70g of 0.1% acetic acid solution dropwise, stir quickly until clear, and obtain a silicone quaternary ammonium salt fabric finishing agent I emulsion with a content of 30% .

Embodiment 2

[0028]

[0029] Take 30g of ternary block copolymerized silicone oil with a molecular weight of about 11000 and 0.3g of epichlorohydrin into a 100mL three-necked flask, stir and raise the temperature to about 95°C for 2.5h. After the reaction is completed, the ring-opening addition reaction product is obtained. Continue to add 0.25g of triethylamine into the bottle, and continue to stir and react at 120°C for 1.5h. After the reaction is completed, the product organosilicon quaternary ammonium salt finishing agent II is obtained.

[0030] Emulsification process: Take 30g of the product, pour it into a 250mL beaker, first add 10 drops of acetic acid, then slowly add 70g of 0.1% acetic acid solution dropwise, stir quickly until clear, and obtain a silicone quaternary ammonium salt fabric finishing agent II emulsion with a content of 30% .

Embodiment 3

[0032]

[0033] Take 30g of ternary block copolymerized silicone oil with a molecular weight of about 6000 and 0.5g of epichlorohydrin into a 100mL three-necked flask, stir and heat up to about 100°C for 2.0h, then add 0.7g of triethanolamine into the bottle, and continue to Stir and react at 90°C for 4 hours. After the reaction is completed, the product organosilicon quaternary ammonium salt fabric finishing agent III is obtained.

[0034] Emulsification process: Take 30g of the product, pour it into a 250mL beaker, add 10 drops of acetic acid first, then slowly add 70g of 0.1% acetic acid solution dropwise, stir quickly until clear, and obtain a silicone quaternary ammonium salt fabric finishing agent III emulsion with a content of 30% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com