Suspension filtering system convenient for sludge discharge

A technology of suspension filtration and filtration area, which is applied in the direction of loose filter material filter, filtration separation, filtration treatment, etc. It can solve the problems that algae are easy to block the filter material, consume large high-quality water source and power supply, and filter material loss, etc., to avoid The thickness of the filter material is quite different, ensuring the effect of backwashing and uniform thickness of the filter material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

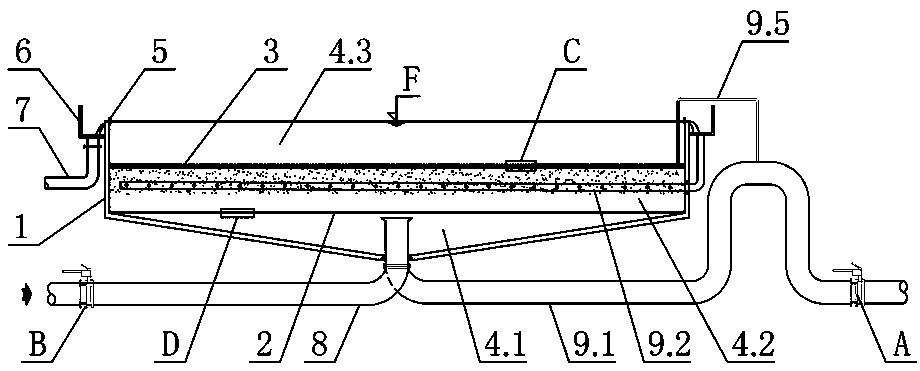

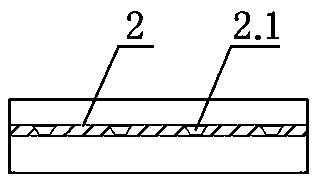

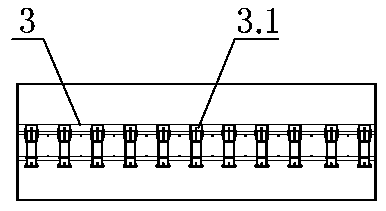

[0029] Such as figure 1 As shown, the suspended filter system for sludge discharge according to the present invention includes a filter tank 1 communicated with the original water channel and a backwash system communicated with the filter tank 1, the lower water distribution roof 2 and the upper filter plate in the filter tank 1 3 Divide it into the lower water distribution area 4.1, the middle filter area 4.2 and the upper clear water storage area 4.3. The middle filter area 4.2 is filled with filter material (filling thickness is about 1m, the diameter of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com