Concrete structure self-immune self-repairing microcapsule and preparation method

A technology for self-repairing microcapsules and concrete structures, applied in the field of concrete and wood engineering, can solve the problems of high cost of raw materials, low damage rate of microcapsules, failure of microcapsules, etc. Corrosion resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

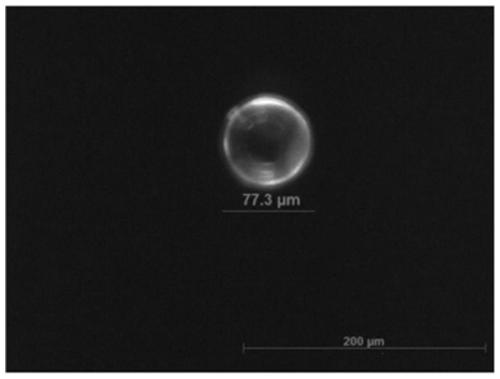

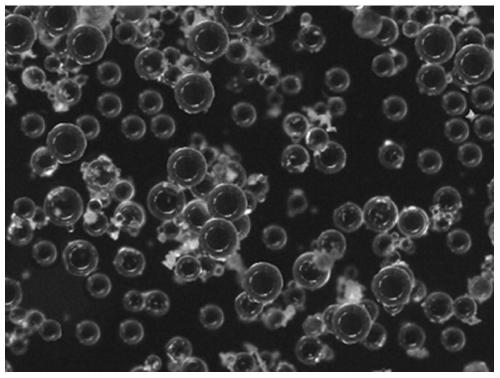

[0025] The self-immune and self-repairing microcapsules include a capsule wall and a core material in the capsule. The capsule wall is made of urea-formaldehyde resin prepared from urea and formaldehyde, and the core material is mainly composed of ethyl phenylacetate and epoxy resin.

[0026] The preparation method of concrete structure self-immunity and self-repairing microcapsules of the present invention comprises the following steps:

[0027] Weigh 0.2g of gum arabic solid, 0.5g of ammonium chloride solid, 0.5g of resorcinol, and 5g of urea in 200ml of purified water to prepare a wall material solution.

[0028] Take another container and add 10g of ethyl phenylacetate and 5g of E-44 type epoxy resin, stir until uniform, and prepare a core material solution.

[0029] After the wall material solution is stirred evenly, hydrochloric acid solution (15% by mass fraction) is added to adjust the wall material solution to be acidic and the pH to be about 3. Add the wall materia...

Embodiment 2

[0037] The preparation method of the self-immune and self-repairing microcapsules for concrete structures in this example is basically the same as that in Example 1, except that the epoxy resin in this example is E-42 type.

[0038] The resulting finished product is a microcapsule whose microscopic shape is close to spherical, which is white macroscopically, with a particle size of 1-150 μm and a specific surface area of 70-110 μm. 2 / kg, the particle refractive index is 1.58.

Embodiment 3

[0040] The preparation method of the self-immune and self-healing microcapsules for concrete structures in this example is basically the same as that in Example 1, except that the epoxy resin in this example is E-20 type.

[0041] The resulting finished product is a microcapsule whose microscopic shape is close to spherical, which is white macroscopically, with a particle size of 50-200 μm and a specific surface area of 50-110 μm. 2 / kg, the refractive index of the particles is 1.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com