Floatation tailings coal slime gradient reduction process

A flotation tailings, step-by-step technology, applied in the direction of solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of centrifuge mesh wear, increase the production cost of enterprises, high moisture content of filter cake, etc., and achieve good production conditions , Improve the uniformity and improve the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

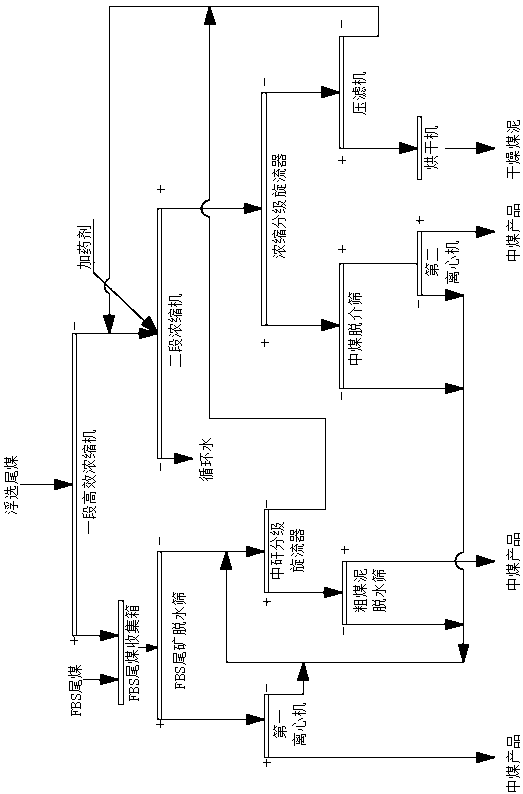

[0026] combine figure 1 As shown, a step reduction recovery process for flotation tailings comprises the following steps;

[0027] Step 1: Flotation tailings are continuously added to the first-stage high-efficiency thickener to control the discharge of the underflow of the first-stage high-efficiency thickener. The particle size range of the first-stage concentrated underflow is 0.25-0.5mm, and the first-stage concentrated underflow is pumped to the FBS tailing coal collection box Inside, the first-stage concentrated underflow is evenly mixed with FBS tailing coal, and the overflow of the first-stage high-efficiency thickener is transported to the second-stage thickener through pipelines;

[0028] Step 2: The first-level concentrated underflow mixed with FBS tailings enters the FBS tailings dewatering screen for dehydration treatment, and the intermediary on the screen is transported to the first centrifuge for processing to obtain medium coal products, and the FBS tailings d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com