Wall material composite material

A wall material and composite material technology, applied in the field of wall material composite materials, can solve the problems of not achieving rapid hardening and high strength, reducing thermal conductivity and dry density, achieving high early strength, reducing bulk density, improving thermal insulation performance and The effect of sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

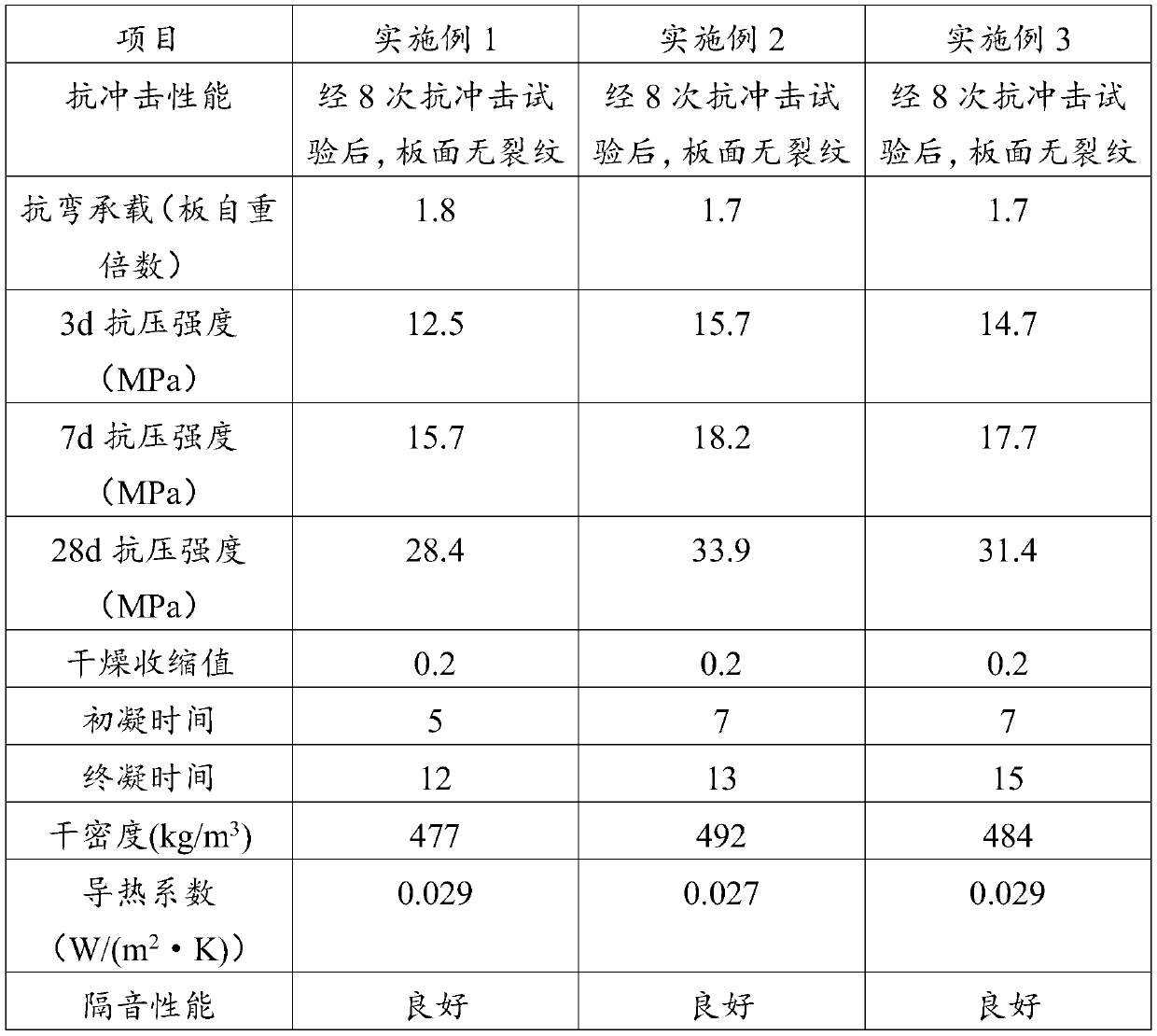

Examples

preparation example Construction

[0033] The present invention also provides a preparation method for the wall material composite described in the above technical solution, comprising the following steps:

[0034] Ordinary portland cement, sulphoaluminate cement, hemihydrate gypsum, anhydrous gypsum, filling aggregate, water reducing agent, reinforcing agent, water repellent agent and thickener are mixed to obtain the composite wall material.

[0035] In the present invention, the order of mixing is preferably to mix Portland cement, sulphoaluminate cement, hemihydrate gypsum, anhydrite and filler aggregate, and then mix with water reducing agent, reinforcing agent, hydrophobic Mixing agent and thickener. In the present invention, the mixing method is preferably stirring. The present invention has no special limitation on the specific operating conditions of the stirring, as long as the raw materials can be mixed evenly.

[0036] In the present invention, the method for applying the wall material composite p...

Embodiment 1

[0043] A kind of wall material composite material, by weight percentage, comprises the following components:

[0044] 2% ordinary Portland cement, 5% sulfoaluminate cement, 65% β-type hemihydrate gypsum, 5% anhydrite, 20% filler aggregate (the mass ratio of slag and fly ash is 2:1, slag and fly ash have a specific surface area of 300m 2 / g), 1.3% polycarboxylate superplasticizer, 1% triethanolamine, 0.5% SHP-50 polysiloxane and 0.2% xanthan gum.

[0045] The above components are mixed to obtain a wall material compound.

Embodiment 2

[0047] A kind of wall material composite material, by weight percentage, comprises the following components:

[0048] 4% ordinary Portland cement, 7% sulphoaluminate cement, 57% β-type hemihydrate gypsum, 7% anhydrite, 22% filler aggregate (the mass ratio of silicomanganese slag and ferronickel slag is 1:1 , the specific surface area of silicomanganese slag and ferronickel slag is 320m 2 / g), 1.8% polycarboxylate superplasticizer, 0.7% calcium formate, 0.4% SHP-50 polysiloxane and 0.1% methyl hydroxypropyl cellulose.

[0049] The above components are mixed to obtain a wall material compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com