Preparation method of emulsion explosive with high sympathetic detonation sensitivity

A technology of emulsified explosive and emulsified matrix, which is applied in explosive processing equipment, explosives, explosive compound components, etc., can solve the problems of affecting blasting effect and safety, incomplete explosion of blasting charge, and reduction of "hot spots of detonation", so as to improve the quality of life. The effect of explosion sensitivity, large explosion distance, and strong low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] A kind of preparation method of the big emulsified explosive of detonation sensitivity of the present invention comprises the following steps:

[0013] Step 1: adding a salt containing a monovalent anion to the first aqueous phase solution to obtain a second aqueous phase solution, the first aqueous phase solution being an aqueous solution in which the solute includes ammonium nitrate and sodium nitrate;

[0014] Step 2: After emulsifying the second aqueous phase solution and the oil phase solution, an emulsified matrix is obtained;

[0015] Step 3: chemically sensitize the emulsified matrix and charge it through a filling machine to obtain an emulsified explosive with high detonation sensitivity.

[0016] The principle of the present invention is: the stability of the emulsion explosive system depends on the interaction of the electric double layer on the surface of the colloidal particles. When the charge of the electric double layer on the surface of the colloidal...

Embodiment 1

[0028] A preparation method for an emulsion explosive with high detonation sensitivity, comprising the steps of:

[0029] Step 1: adding a salt containing a monovalent anion to the first aqueous phase solution to obtain a second aqueous phase solution, the first aqueous phase solution being an aqueous solution in which the solute includes ammonium nitrate and sodium nitrate;

[0030] Step 2: After emulsifying the second aqueous phase solution and the oil phase solution, an emulsified matrix is obtained;

[0031] Step 3: chemically sensitize the emulsified matrix and charge it through a filling machine to obtain an emulsified explosive with high detonation sensitivity.

[0032] The percentage by weight of each component in the above-mentioned second aqueous phase solution is 79% to 82% of ammonium nitrate, 3% to 6% of sodium nitrate, and 9% to 16% of water, wherein the salt containing monovalent anions The ratio of the weight to the total weight of the second aqueous phase s...

Embodiment 2

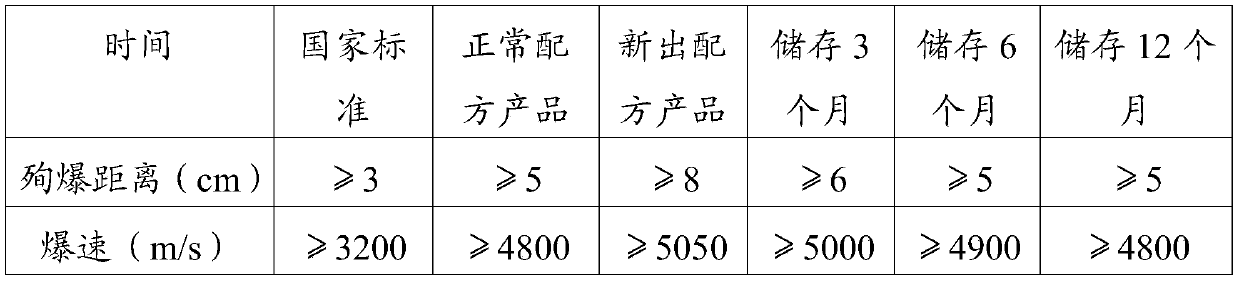

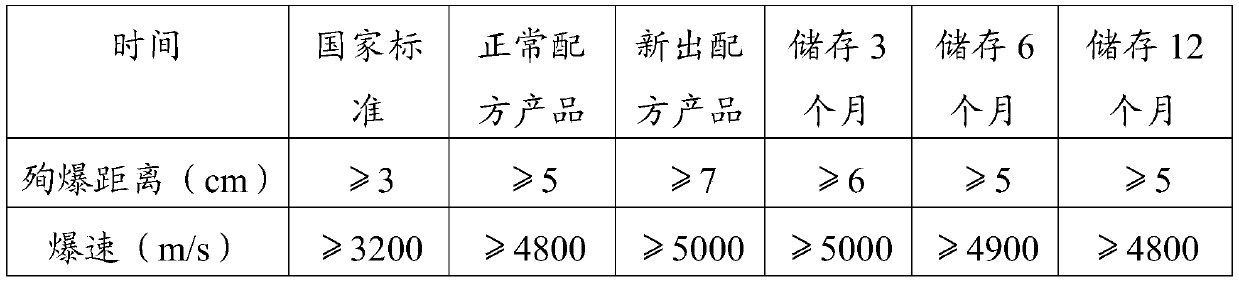

[0035] A kind of preparation method of high temperature sensitized emulsified explosive with high detonation sensitivity, prepare 1t of this aqueous phase solution including 799kg ammonium nitrate, 60kg sodium nitrate, 140kg water and 1kg sodium chloride, the prepared aqueous phase solution and oil phase The solution was emulsified at 95°C to obtain an emulsified matrix, which was chemically sensitized and filled with a filling machine, packed into rolls with a weight of 300g, a diameter of 32mm, and a length of 34cm; The drug rolls are packed into one bag, and four bags of drug rolls are packed into a box; the explosive performance of the emulsion explosives from new products to storage for 12 months is tested respectively, as shown in Table 1;

[0036] Table 1

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com