The preparation method of dl-p-thymphenyl phenylserine ester

A technology of methylsulfonyl phenylserine ethyl ester and methanol, which is applied in the field of preparation of DL-p-thymphenyl phenylserine ester, can solve the problems of long recycling period and low production capacity, so as to improve efficiency, simplify production process, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

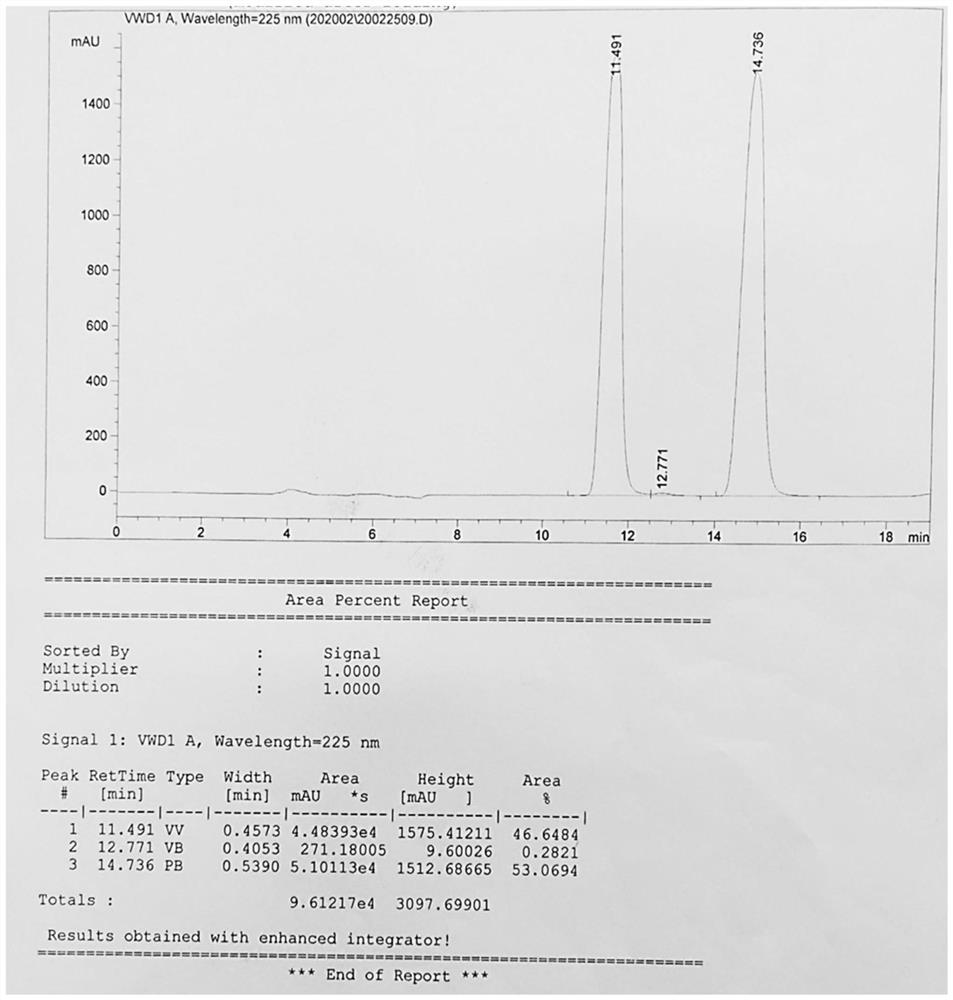

[0038] Take L- p-methyl sulfonylphenylserine ethyl ester 28.7g (0.1mol), disperse it into 170g of water, control the temperature at 15 °C (temperature difference ± 2 °C), insulation stirring for 30 minutes, add a concentration of 30wt% sodium hydroxide solution 3.9g, insulation reaction for 8 hours, after which the pH value was adjusted to 7.0, and then filtered to obtain the product D- p-methyl sulfonyl phenylserine ethyl ester and L- p-methylsulfonylphenylserine ethyl ester for a total of 18.52g. as Figure 1 As shown, the characteristic peak at 11.491min is the characteristic peak of D- p-methylsulfonyl phenylserine ethyl ester, and the characteristic peak at 14.736min is L- p-methylsulfonylphenylserine ethyl characteristic peak, and the ratio of D- p-methylsulfonylphenylserine ethyl ester and L- p-methylsulfonylphenylserine ethyl ester is 46.6%:53.1%, that is, 1:1.1, close to 1:1.

Embodiment 2

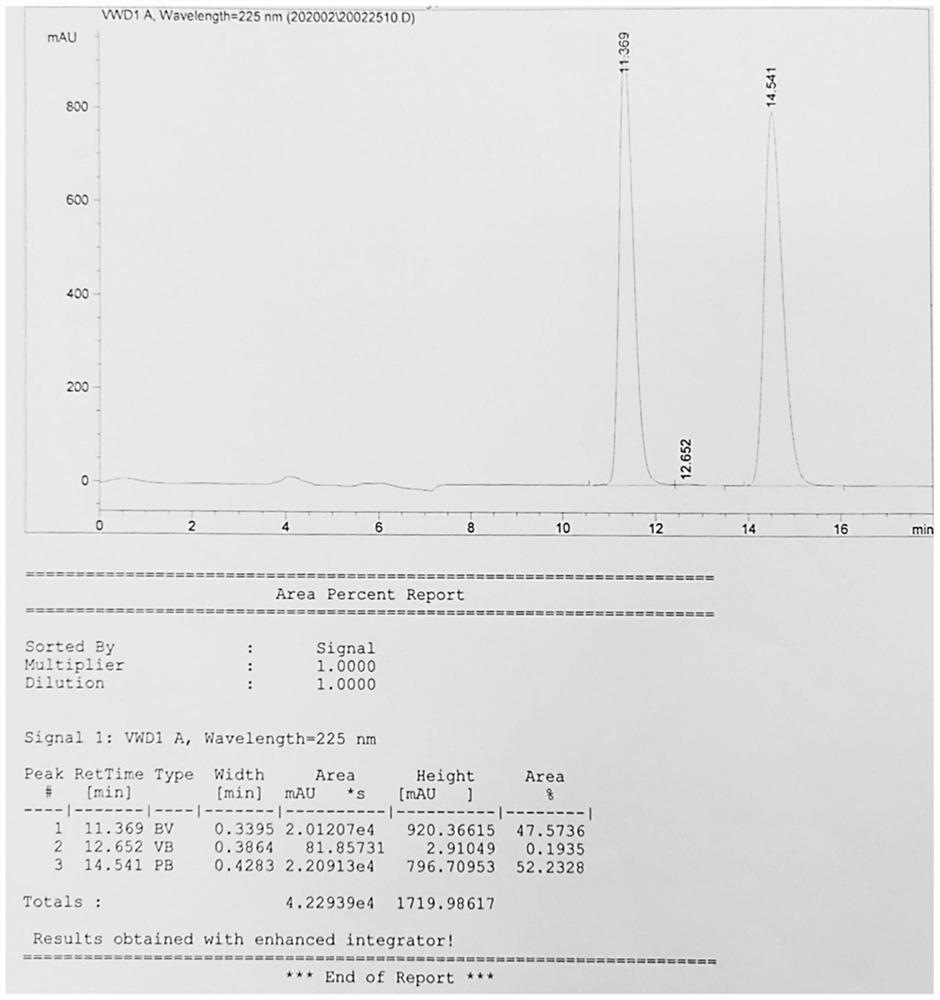

[0040] Take L- p-methyl sulfonylphenylserine ethyl ester 28.7 g (0.1 mol), dispersed into 170 g ethanol, the temperature was controlled at 15 °C (temperature difference ± 2 °C), after heat preservation stirring for 30 minutes, the concentration of 10% sodium hydroxide solution 11.5 g, the insulation reaction for 10 hours, and then the pH value was adjusted to 7.0, filtered to give the product D- p-methyl sulfone phenyl serine ethyl ester and L- p-methyl sulfone phenyl serine ethyl ester a total of 15.32 g. as Figure 2 As shown, at 11.369min the characteristic peak is the characteristic peak of D- p-methylsulfonylphenylserine ethyl ester, at 14.541min the characteristic peak is L- p-methylsulfonylphenylserine ethyl ester characteristic peak, the ratio of D- p-methyl sulfonylphenylserine ethyl ester and L- p-methylsulfonylphenylserine ethyl ester is 47.6%: 52.2%, that is, 1: 1.1, close to 1: 1.

Embodiment 3

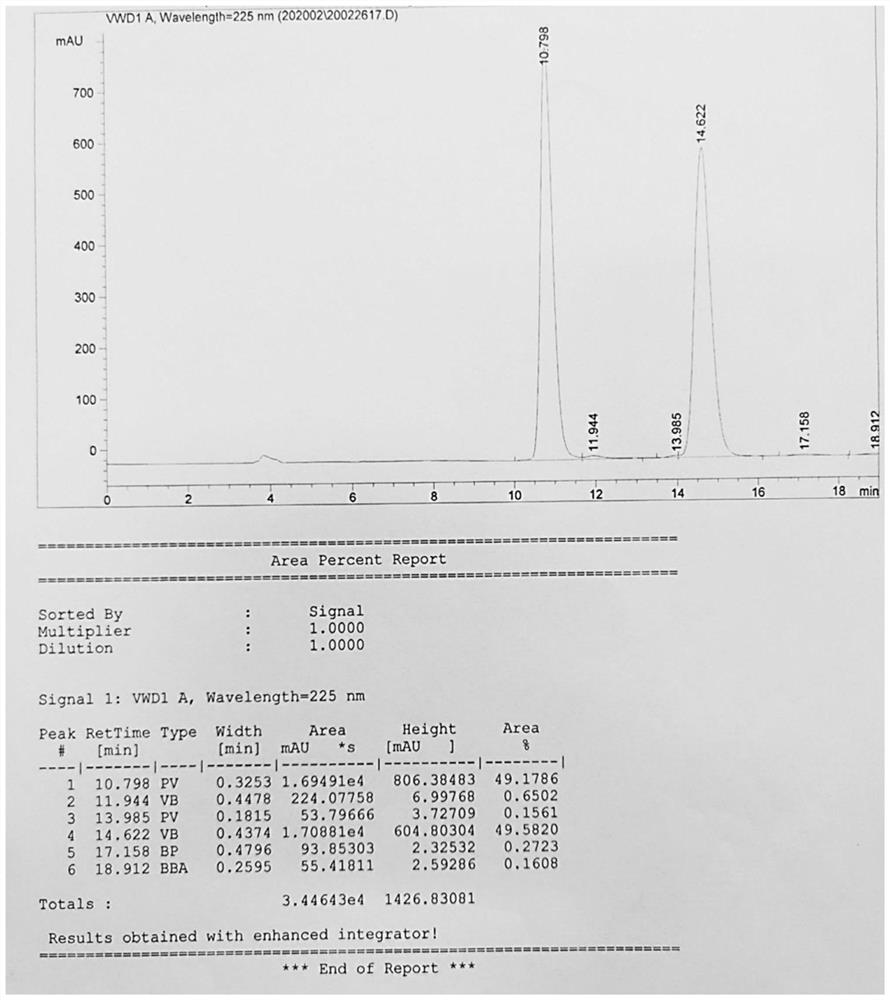

[0042] Take L- p-methyl sulfonylphenylserine ethyl ester 28.7g (0.1mol), dispersed into 170g of methanol, the temperature was controlled at 15 °C (temperature difference ±2 °C), stirred for 30 minutes, with 10% sodium hydroxide solution 11.5g, insulation reaction for 10 hours, and then the pH value was adjusted to 7.0, filtered to give the product D- p-methylsulfonyl phenylserine ethyl ester and L- p-methyl sulfonylphenylserine ethyl ester a total of 13.32g. as Figure 3As shown, at 10.798min the characteristic peak is D- p-methylsulfonylphenylserine ethyl characteristic peak, at 14.622min the characteristic peak is L- p-methylsulfonylphenylserine ethyl characteristic peak, the ratio of D- p-methylsulfonylphenylserine ethyl ester and L- p-methylsulfonylphenylserine ethyl ester is 49.2%: 49.6%, that is, 1: 1.0, close to 1: 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com