Synthesis method of 5-bromo-2, 2-dimethyl-5-(4-methylsulfonylphenyl) furan-3 (2H)-one

The technology of a methanesulfonyl phenyl group and a synthesis method, which is applied in the field of organic synthesis, can solve the problems of large residual fluctuation of reaction raw materials, unsuitable for industrial production, etc., and achieves the effects of avoiding the acid waste water of chromium, easy industrial production, and low environmental protection pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

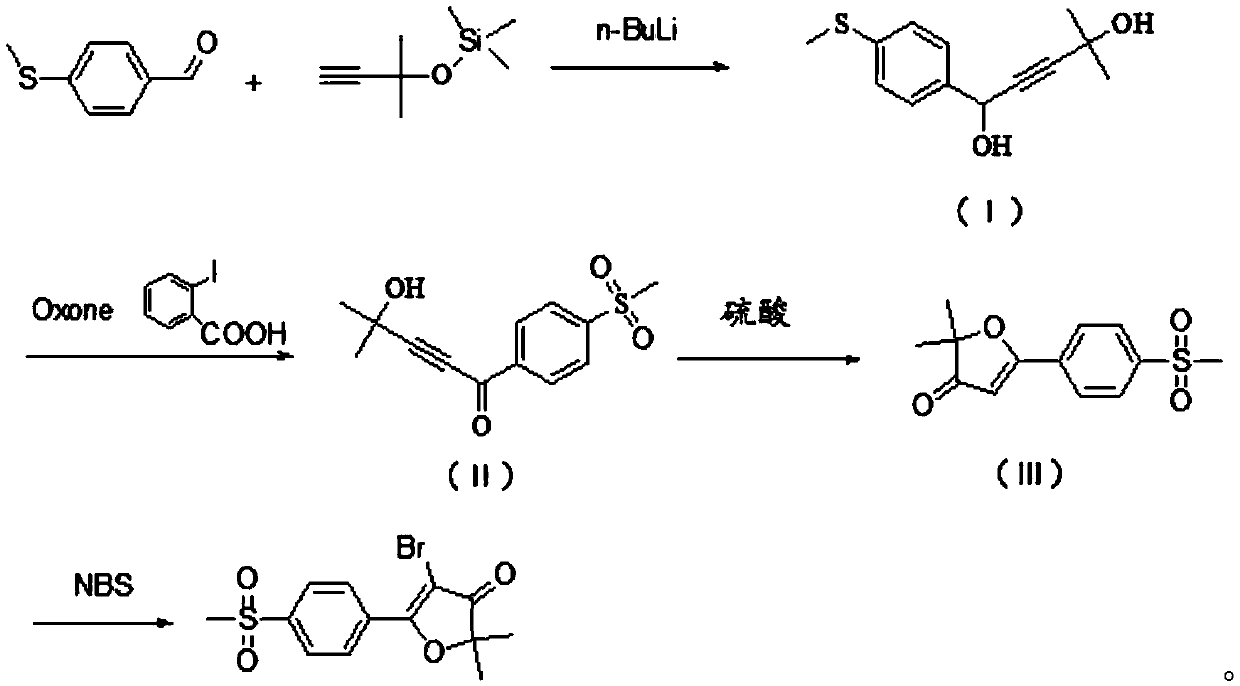

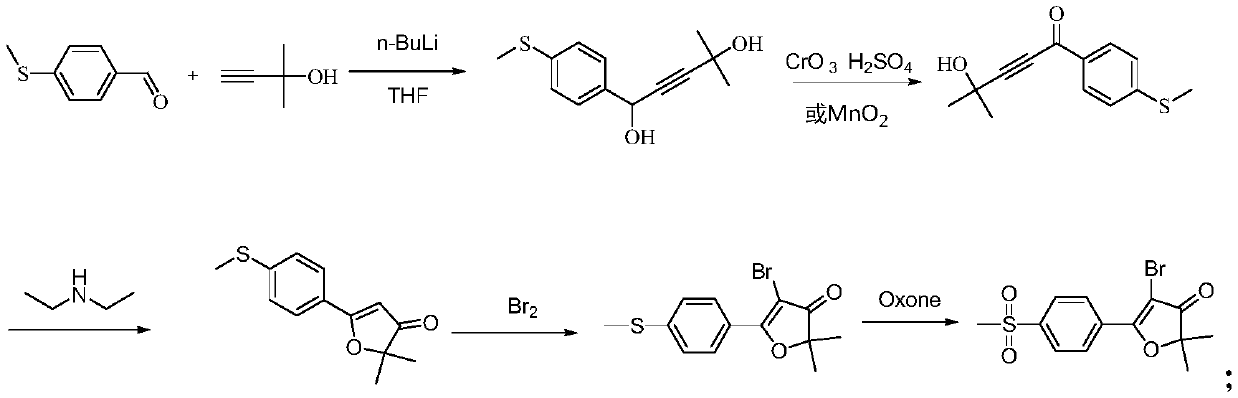

[0035] The present invention provides a method for synthesizing 5-bromo-2,2-dimethyl-5-(4-methanesulfonylphenyl)furan-3(2H)-one, which comprises the following steps:

[0036] S1: 4-Methylthiobenzaldehyde and [(1,1-dimethyl-2-propynyl)oxy]trimethylsilane undergo a nucleophilic addition reaction under the action of n-butyl lithium to form Compound of formula (I);

[0037] S2: S1 compound of formula (I) reacts with Oxone and o-iodobenzoic acid to produce compound of formula (II);

[0038] S3: S2 compound of formula (II) undergoes ring-closing reaction under the catalysis of sulfuric acid to produce compound of formula (III);

[0039] S4: The compound of formula (Ⅲ) of S3 reacts with NBS to produce 5-bromo-2,2-dimethyl-5-[4-(methylsulfonyl)phenyl]furan-3(2H)-one ;

[0040] The synthetic route is as follows:

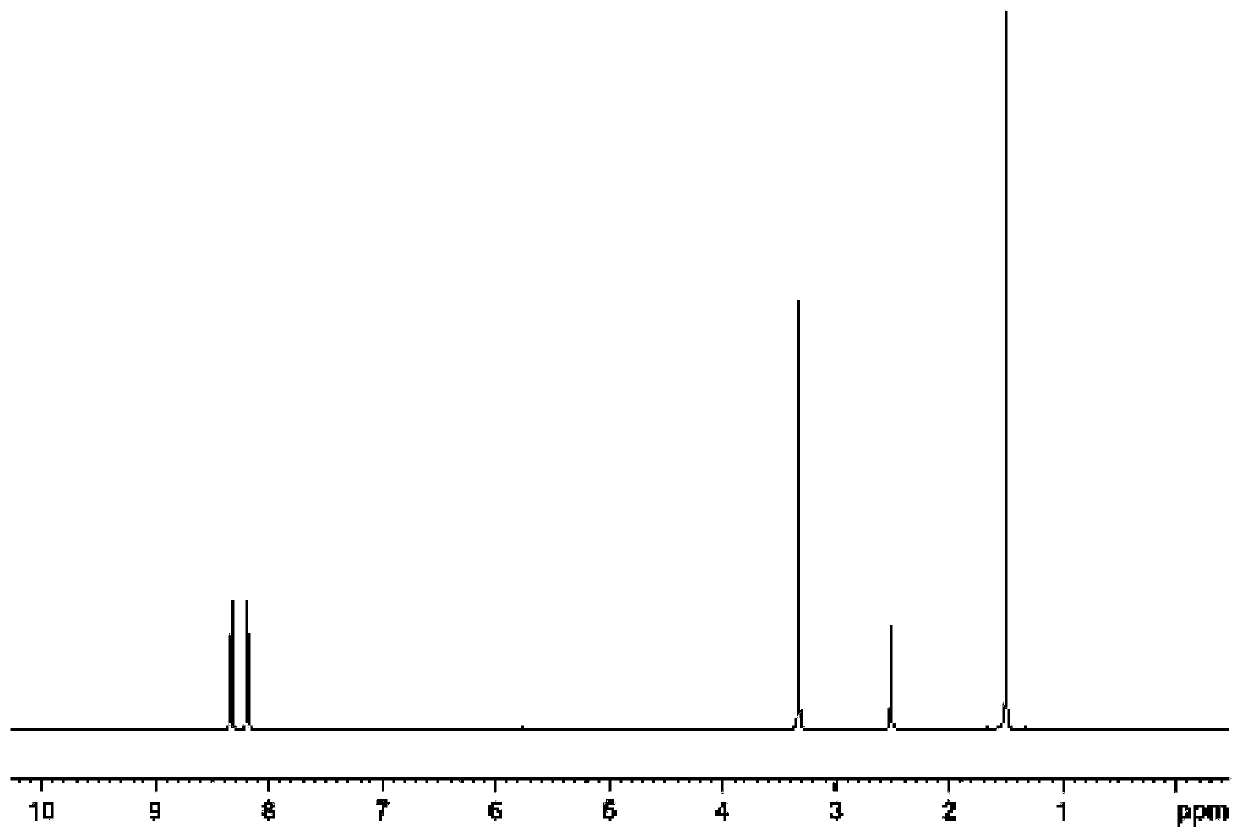

[0041]

Embodiment 1

[0043] A method for synthesizing 5-bromo-2,2-dimethyl-5-(4-methanesulfonylphenyl)furan-3(2H)-one, which specifically includes the following steps:

[0044] Step 1. Synthesis of the compound of formula (I):

[0045] Under the protection of nitrogen (500mL / min), add [(1,1-dimethyl-2-propynyl) to a 5000mL three-necked flask equipped with mechanical stirring, thermometer, Y-shaped tube, and 500mL constant pressure dropping funnel. 185.60g of oxy]trimethylsilane, 1L of tetrahydrofuran, after stirring for 10min, slowly lower the temperature to -90℃, start to add 594.5mL of n-butyllithium dropwise, after stirring for 1h at -90℃, add dropwise configuration to the reaction system After adding 124.81g of 4-methylthiobenzaldehyde and 124mL of tetrahydrofuran, the reaction was stopped after stirring at -90℃ for 2h. The reaction solution was slowly poured into aqueous hydrochloric acid (concentrated hydrochloric acid: 187.2mL, water: 324.5mL ), stir for 1 hour and then separate, collect the or...

Embodiment 2

[0053] A method for synthesizing 5-bromo-2,2-dimethyl-5-(4-methanesulfonylphenyl)furan-3(2H)-one, which specifically includes the following steps:

[0054] Step 1. Synthesis of the compound of formula (I):

[0055] Under the protection of nitrogen (500mL / min), add [(1,1-dimethyl-2-propynyl) to a 5000mL three-necked flask equipped with mechanical stirring, thermometer, Y-shaped tube, and 500mL constant pressure dropping funnel. 185.60g of oxy]trimethylsilane, 876mL of tetrahydrofuran, after stirring for 10min, slowly decrease the temperature to -70℃, start to add 594.5mL of n-butyllithium dropwise, after stirring at -70℃ for 1h, add dropwise configuration to the reaction system After adding 124.81g of 4-methylthiobenzaldehyde and 124mL of tetrahydrofuran, the reaction was stopped after stirring at -70℃ for 2h. The reaction solution was slowly poured into aqueous hydrochloric acid (concentrated hydrochloric acid: 187.2mL, water: 324.5mL ), stir for 1h and then separate, collect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com