Ultraviolet-induced gradient distribution POSS microsphere/polyarylether sulfuryl composite proton exchange membrane and preparation method thereof

A gradient distribution, sulfonated polyaryl ether sulfone technology, applied in the field of proton exchange membranes, can solve the problems of PEM proton conductivity decrease and swelling rate increase, and achieve good interfacial compatibility, reduce swelling, and shorten the time period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

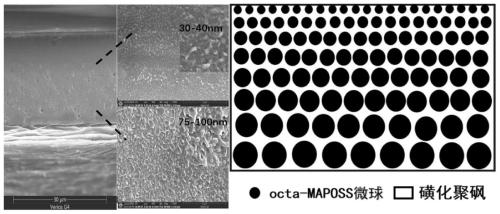

[0051] Preparation of nano-octa-MAPOSS microspheres / sulfonated polyarylethersulfone membrane with gradient distribution induced by ultraviolet light:

[0052] Prepare a 0.4g / mL sulfonated polyarylethersulfone solution with DMF as a solvent, add 2.5% TPO by mass fraction, and 15% octa-MAPOSS into the prepared sulfonated polyarylethersulfone solution respectively. Mix evenly at 25°C and 50% RH, and make a film by scraping. Expose the scraped film to a 32W UV lamp for 30 minutes, and finally place it in a vacuum oven at 40°C until the solvent is completely evaporated. The thickness of the liquid film is controlled at 200±5 μm, and the thickness of the dried film is 30±5 μm.

Embodiment 2

[0054] Preparation of nano-octa-MAPOSS microspheres / sulfonated polyarylethersulfone membrane with gradient distribution induced by ultraviolet light:

[0055] Prepare a 0.4g / mL sulfonated polyarylethersulfone solution with DMF as a solvent, add TPO with a mass fraction of 5%, and 15% octa-MAPOSS into the prepared sulfonated polyarylethersulfone solution respectively. Mix evenly at 25°C and 50% RH, and make a film by scraping. Expose the scraped film to a 32W UV lamp for 30 minutes, and finally place it in a vacuum oven at 40°C until the solvent is completely evaporated. The thickness of the liquid film is controlled at 200±5 μm, and the thickness of the dried film is 30±5 μm.

Embodiment 3

[0057] Preparation of nano-octa-MAPOSS microspheres / sulfonated polyarylethersulfone membrane with gradient distribution induced by ultraviolet light:

[0058] Prepare a 0.4g / mL sulfonated polyarylethersulfone solution with DMF as a solvent, add 2.5% TPO by mass fraction, and 15% octa-MAPOSS into the prepared sulfonated polyarylethersulfone solution respectively. Mix evenly at 25°C and 50% RH, and make a film by scraping. Expose the scraped film to a 32W UV lamp for 30 minutes, and finally place it in a vacuum oven at 40°C until the solvent is completely evaporated. The thickness of the liquid film is controlled at 150±5 μm, and the thickness of the dried film is 25±5 μm.

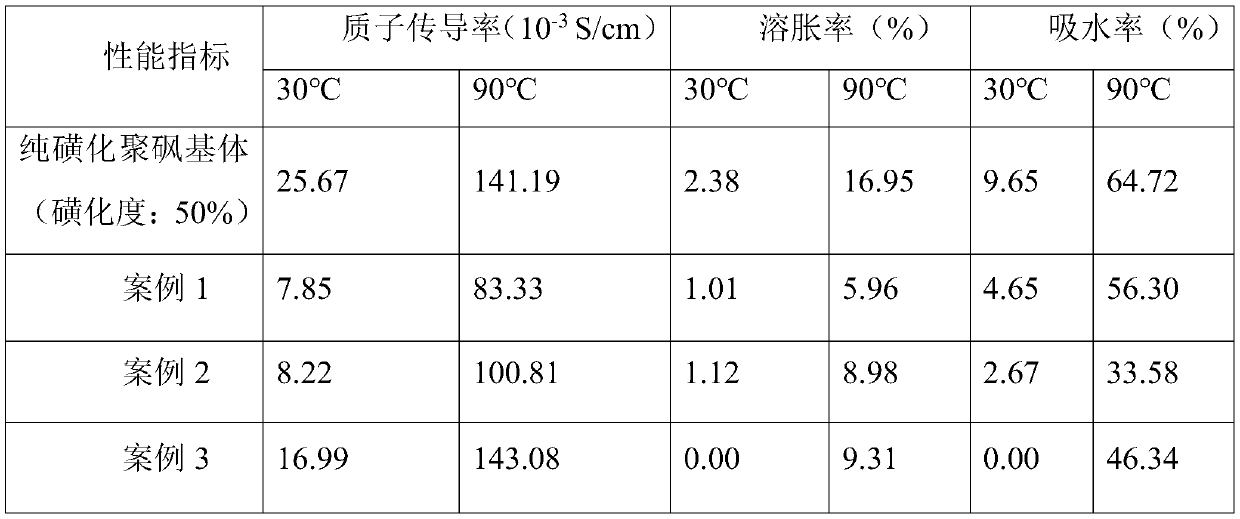

[0059] The performance data measured by the film made by the above examples are shown in the following table:

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com