Preparation method of silicotungstic acid/silicon dioxide polyvinyl alcohol proton exchange membrane

A proton exchange membrane and polyvinyl alcohol technology, applied in electrochemical generators, fuel cell parts, fuel cells, etc., can solve the problems of high swelling rate, low alcohol resistance, low methanol permeability, etc., and achieve swelling Low rate, enhanced conductivity, and reduced permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

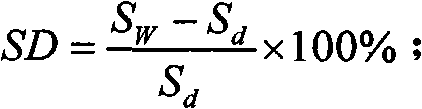

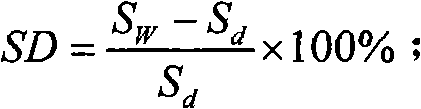

[0013] Dissolve 20 grams of polyvinyl alcohol in 150 milliliters of water to form a polymer solution A, heat the polymer solution A to 90°C, and stir at this temperature for 2 hours to obtain a solution B, then lower the temperature of the solution B to 60°C, Add 2.5g of silicon tetrachloride and 2.5g of sodium tungstate to solution B, stir at 60°C for 2 hours and then cool down to room temperature to form a uniform solution C; pour solution C on a polytetrafluoroethylene plate and Dry to form a film, the film thickness is controlled at 0.12mm, and the drying temperature is 50°C to obtain a silicotungstic acid / silica polyvinyl alcohol proton exchange membrane. Soak the membrane in deionized water for 12 hours before use. The electrical conductivity was measured by the two-electrode AC impedance method, and the swelling behavior of the film was characterized by the degree of swelling (SD). First, the dry film was cut into a rectangular diaphragm (with an area of S d ), immer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com