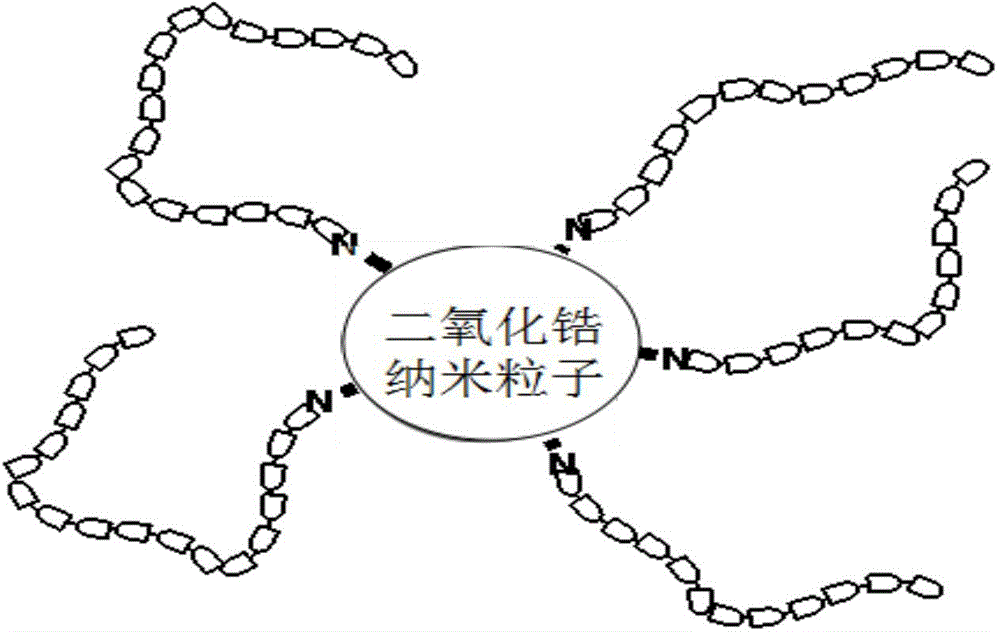

Preparation of organic-inorganic composite membrane and application thereof in alkaline fuel cell

A composite membrane and inorganic nano-filler technology, which is applied to fuel cell parts, battery pack parts, circuits, etc., to achieve the effects of improving alkali stability, simple and convenient operation, and low swelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

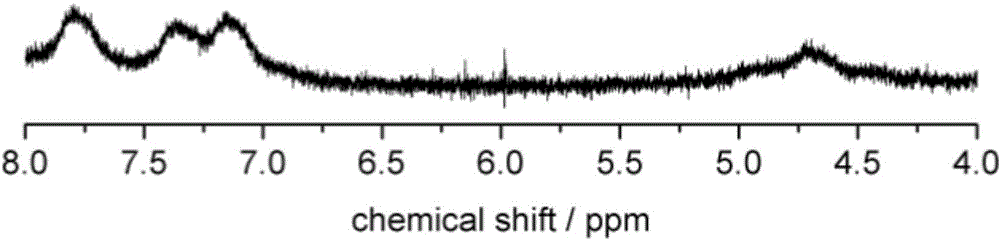

[0043]Chloromethylation of polymers: add 1g of polyether ether ketone to 70ml of concentrated sulfuric acid with a concentration of 98%, add 8ml of chloromethyl methyl ether, react at 0°C for a certain period of time, pour into ice water and wash until neutral, Filter and dry to obtain the crude product of chloromethylated polyetheretherketone; pour 1g of the crude product into 16ml of organic solvent NMP, dissolve it and pour it into the precipitant for soaking, filter and dry to obtain the pure product CMPEEK of chloromethylated polyetheretherketone ; HNMR spectrum ( figure 2 ) to 4.72ppm, the characteristic peak of H in chloromethyl appeared, which proved the successful synthesis of chloromethylated polyetheretherketone;

[0044] Preparation of alkaline anion composite membrane solution:

[0045] (1) Dissolve 1 g of the chloromethylated product in 20 ml of organic solvent N,N-dimethylacetamide DMAC;

[0046] (2) Ultrasonic dispersion of inorganic nanoparticles zirconium ...

Embodiment 2

[0052] Chloromethylation of polymers: Add 1g of polyether ether ketone to 60ml of concentrated sulfuric acid with a concentration of 98%, add 20ml of chloromethyl octyl ether, and react at 0°C for 7 minutes; pour into ice water and wash until neutral , filter and dry to obtain the crude product of chloromethylated polyetheretherketone; pour the crude product into 7ml of organic solvent NMP, dissolve it and pour it into the precipitant for soaking, filter and dry to obtain the pure product CMPEEK of chloromethylated polyetheretherketone ;

[0053] Preparation of alkaline anion composite membrane solution:

[0054] (1) Dissolve 1 g of the chloromethylated product in 20 ml of organic solvent N,N-dimethylacetamide DMAC;

[0055] (2) ultrasonically disperse inorganic nanoparticles zirconium dioxide and organic solvent N,N-dimethylacetamide DMAC for 60 minutes to obtain a uniformly dispersed suspension solution; the mass percentages of inorganic nanoparticles in chloromethylated po...

Embodiment 3

[0062] Chloromethylation of polymers: Add 1 g of polyether ether ketone to 60 ml of concentrated sulfuric acid with a concentration of 98%, add 20 ml of chloromethyl octyl ether, and react at -10°C for 20 minutes; pour into ice water and wash until Neutral, filter and dry to obtain the crude product of chloromethylated polyetheretherketone; pour the crude product into 15ml of organic solvent NMP, dissolve it, pour it into the precipitant for soaking, filter and dry to obtain pure chloromethylated polyetheretherketone Product CMPEEK;

[0063] Preparation of alkaline anion composite membrane solution:

[0064] (1) Dissolve 1 g of the chloromethylated product in 20 ml of organic solvent N,N-dimethylacetamide DMAC;

[0065] (2) ultrasonically disperse inorganic nanoparticles zirconium dioxide and organic solvent N,N-dimethylacetamide DMAC for 30 minutes to obtain a uniformly dispersed suspension solution; inorganic nanoparticles account for chloromethylated polyetheretherketone m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com