Cadmium-free quantum dot and preparation method thereof

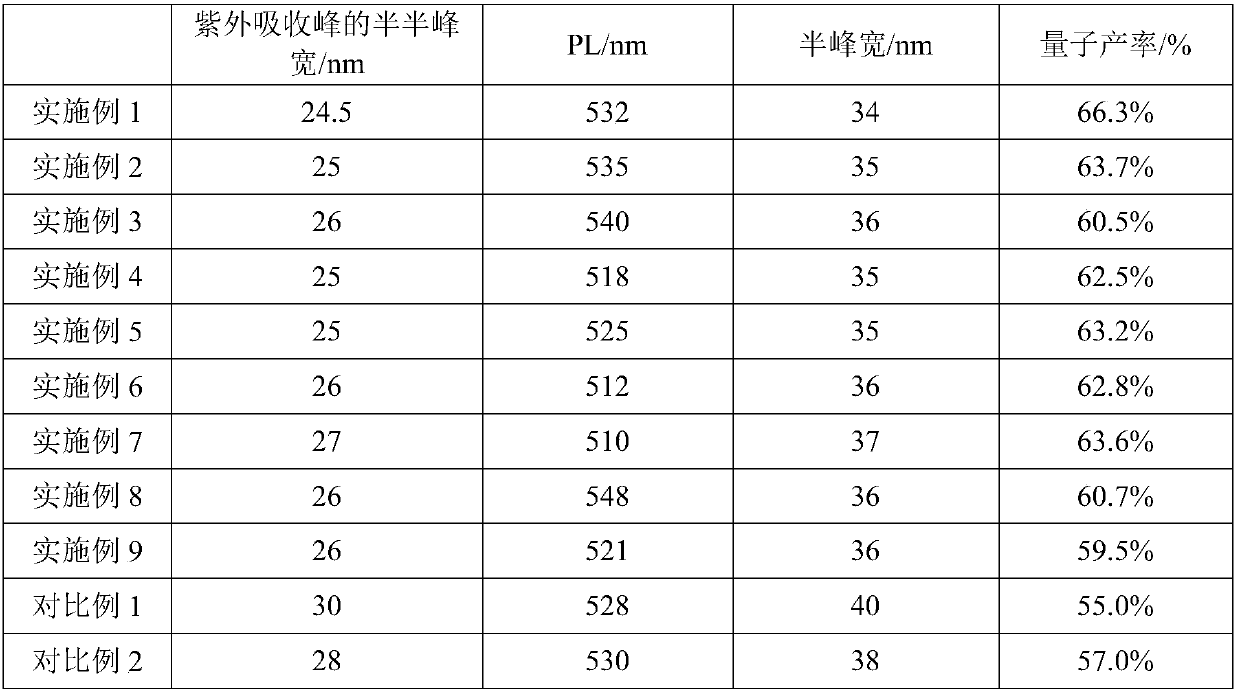

A technology for quantum dots and precursors, which is applied to the field of cadmium-free quantum dots and their preparation, can solve the problems of low luminous efficiency and large luminescence half-peak width, and achieves the effects of improving luminous efficiency and reducing half-peak width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

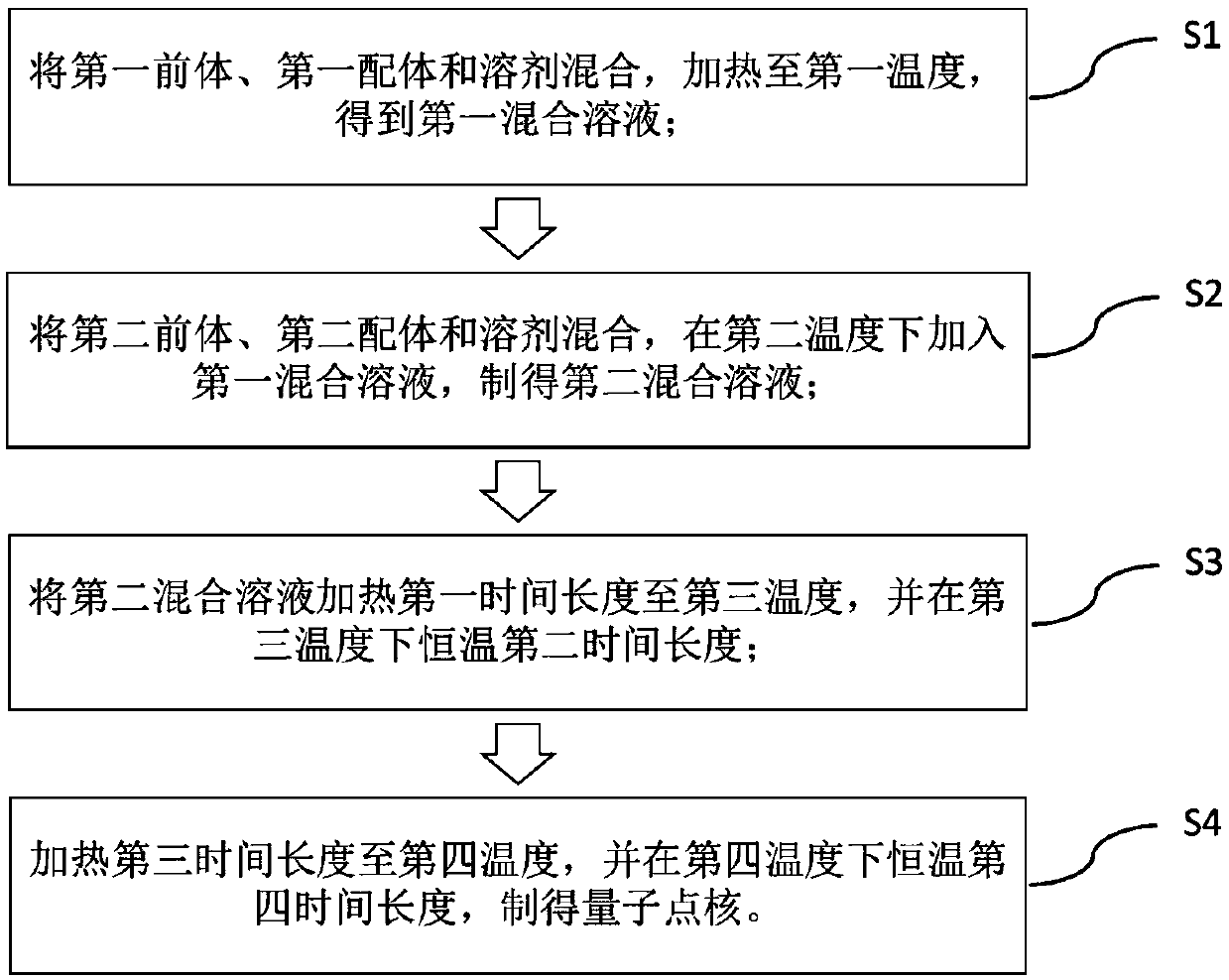

[0025] As described in the background art, the cadmium-free quantum dots in the prior art have low luminous efficiency and large luminous half-peak width. In order to solve the above technical problems, the present invention provides a preparation method of cadmium-free quantum dots, such as figure 1 As shown in the figure, the following steps are included: S1, mixing the first precursor, the first ligand and the solvent, and heating to a first temperature to obtain a first mixed solution; S2, mixing the second precursor, the second ligand and the solvent , adding the first mixed solution at the second temperature to obtain the second mixed solution; S3, heating the second mixed solution for a first time length to a third temperature, and maintaining a constant temperature at the third temperature for a second time length; S4, Heating for a third period of time to a fourth temperature, and constant temperature at the fourth temperature for a fourth period of time, prepares qua...

Embodiment 1

[0047] The preparation method of the present embodiment comprises the following steps:

[0048] First, weigh 0.2 mmol In(Ac) 3 (Indium acetate), 0.6 mmol OA (oleic acid), 5.0 g ODE (octadecene), were added to a 100 mL three-necked flask, N 2 Heating to 170 ℃ in the exhaust state to dissolve, and then cooling to room temperature.

[0049] Then, a mixed solution of 0.1 mmol of TMS-P (tris(trimethylsilyl)phosphine), 0.5 mL of TOP, and 0.5 mL of ODE (octadecene) was added to the above solution at room temperature.

[0050] Next, heat from room temperature (25°C) to 150°C over a period of 5 minutes, and maintain a constant temperature for 2 minutes; then heat to 300°C for 5 minutes, and perform a constant temperature reaction for 2 minutes to obtain an InP core solution.

[0051] Finally, the reaction temperature was lowered to 150 °C and 1.5 mmol of ZnAc was added 2 (zinc acetate), exhaust for 30min, heat up to 280°C, add 1mL Se-TOP (0.1mmol / mL) (selenium-trioctylphosphine) to ...

Embodiment 2

[0053] The preparation method of the present embodiment comprises the following steps:

[0054] First, weigh 0.2 mmol In(Ac) 3 (Indium acetate), 0.6 mmol OA (oleic acid), 5.0 g ODE (octadecene), were added to a 100 mL three-necked flask, N 2 Heating to 170 ℃ in the exhaust state to dissolve, and then cooling to room temperature.

[0055] Then, a mixed solution of 0.1 mmol of TMS-P (tris(trimethylsilyl)phosphine), 0.5 mL of TOP, and 0.5 mL of ODE (octadecene) was added to the above solution at room temperature.

[0056] Next, heat from room temperature to 85°C over a period of 10 minutes, and maintain a constant temperature for 5 minutes; then heat to 150°C for 10 minutes, then heat to 300°C for 5 minutes, and react at a constant temperature for 2 minutes to obtain an InP core solution.

[0057] Finally, the reaction temperature was lowered to 150 °C and 1.5 mmol of ZnAc was added 2 (zinc acetate), exhaust for 30min, heat up to 280°C, add 1mL Se-TOP (0.1mmol / mL) (selenium-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com