Singe-stage radial turbine power generating system capable of balancing axial force through air bearing

A technology of air bearings and power generation systems, which is applied to bearings, shafts and bearings, engine components, etc., can solve the problems of high speed and unsuitable power generation equipment, and achieve high power generation efficiency, low gas consumption, and enhanced bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

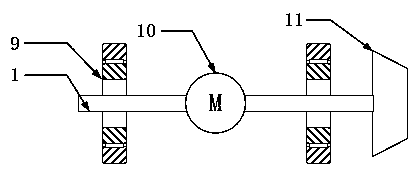

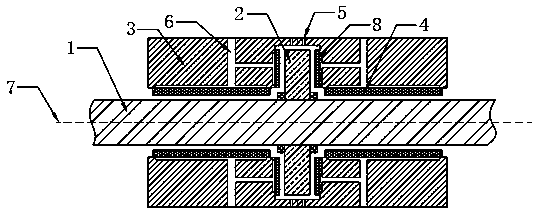

[0020] See Figure 1 to Figure 2 In this embodiment, a single-stage radial turbine power generation system that uses air bearings to balance the axial force is characterized by comprising a rotating shaft 1, an air bearing 9, a high-speed permanent magnet generator 10 and a radial transmission Level 11, the high-speed permanent magnet generator 10 and the radial turbine 11 are connected to the rotating shaft 1, and the air bearing 9 is arranged on the outside of the rotating shaft 1. The radial turbine 11 enters the superheated steam to produce work, which is transferred to the high-speed permanent magnet through the rotating shaft 1. The magneto generator 10 generates power and the air bearing 9 plays the role of bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com