A gasification device for a dual-fuel engine lng high and low pressure gas supply system

A technology of gas supply system and gasification device, which is applied in the direction of fuel, gas fuel, pipeline system, etc., can solve the problems of difficulty in designing and building LNG-powered ships, and achieve the effect of precise control and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

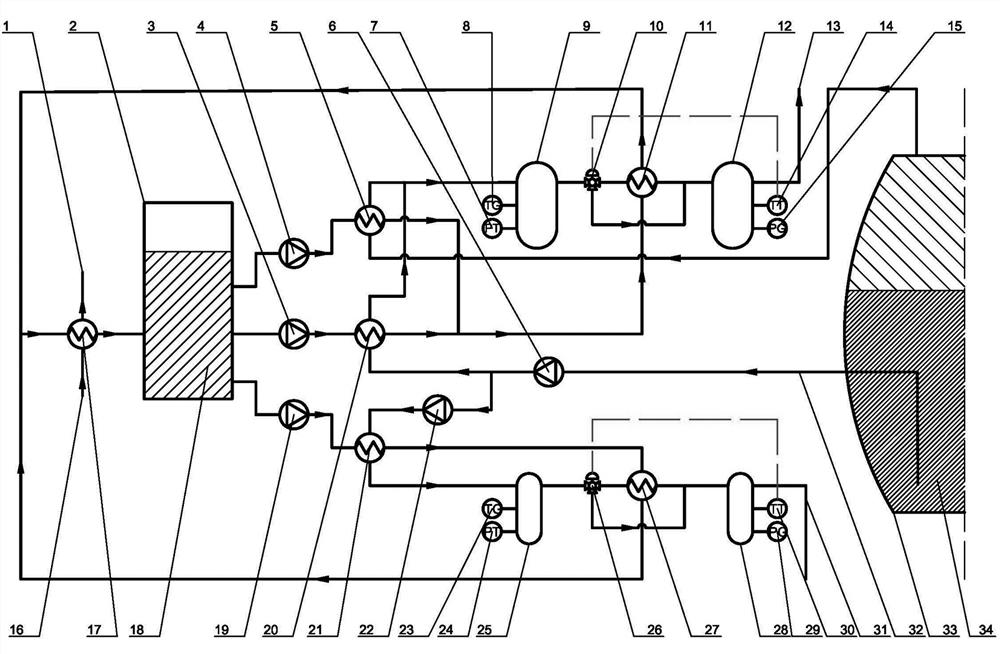

[0015] In order to further illustrate the technical means and work capabilities adopted by the present invention to achieve the purpose of the invention, the specific operation process, structural composition and effect of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the gasification unit includes a high-pressure gasifier 21, a low-pressure gasifier 20, a BOG heat exchanger 5, a heater 17, a heating medium container 2, a medium delivery pump 19 for a high-pressure gasification branch, and a low-pressure gasification branch Medium delivery pump 3 of the BOG heating branch, water / ethylene glycol (heating medium) delivery pump 4 of the BOG heating branch, low-pressure buffer tanks (9, 12), high-pressure buffer tanks (25, 28), high-pressure NG heat exchanger 27, Low pressure NG heat exchanger 11.

[0017] Water / ethylene glycol 18 is used as a low-freezing-point heat-exchanging medium in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com