AGV system based on double control panels and path planning method

A path planning and control board technology, applied in the direction of control/adjustment system, non-electric variable control, two-dimensional position/channel control, etc., can solve the problem of increasing the number of AGV turns and moving distance, increasing task execution time, and path redundancy Increased nodes and other issues to achieve the effect of improving flexibility and operating efficiency, improving operating efficiency, and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

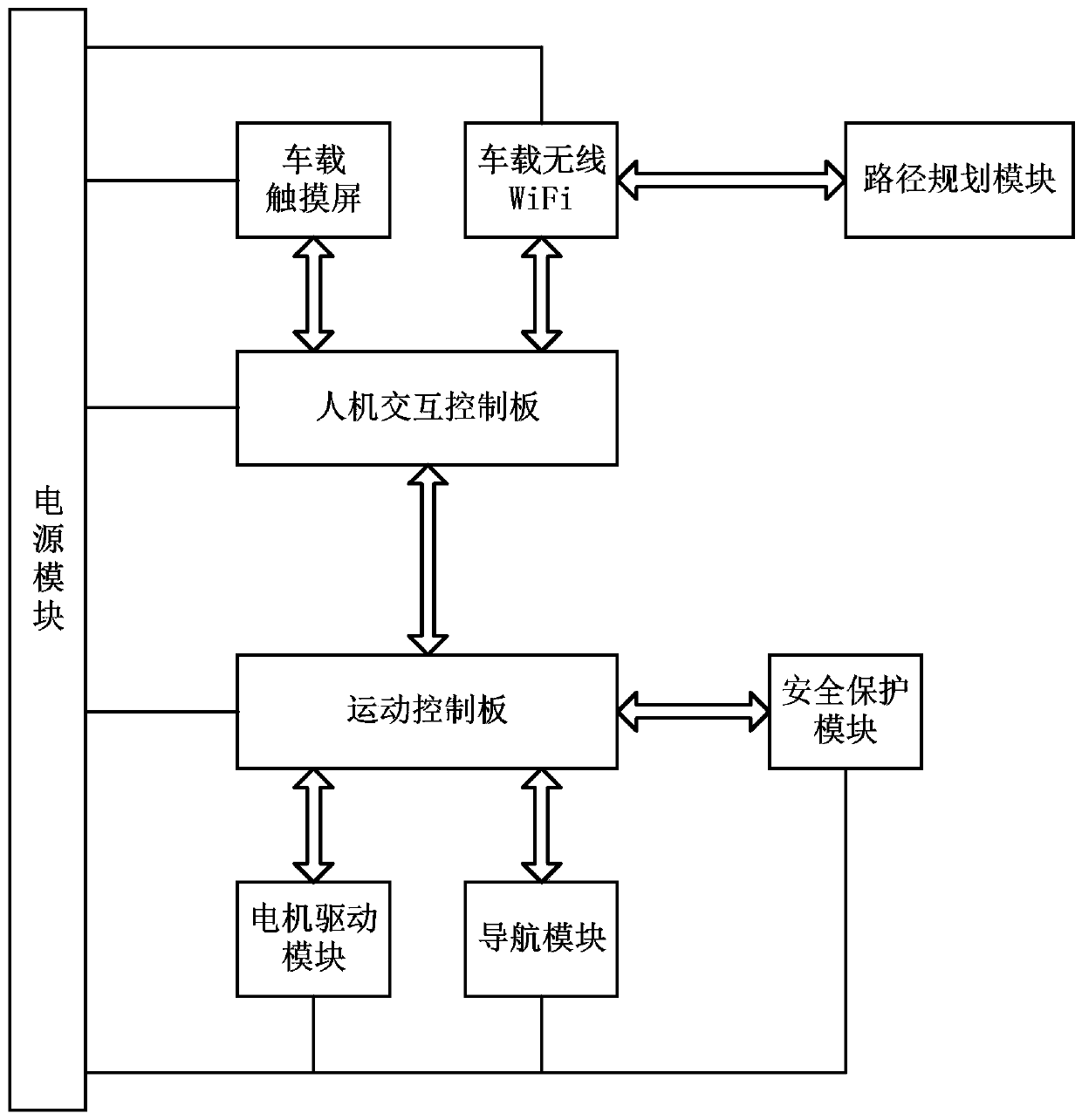

[0095] Such as figure 1 As shown, an AGV system based on dual control boards specifically includes the following modules:

[0096] Motion control board, human-computer interaction control board, motor drive module, navigation module, safety protection module, power supply module, vehicle touch screen, vehicle WiFi module, and path planning module.

[0097] The motion control board is implemented with a 32-bit STM32F103RBT6 single-chip microcomputer, and the human-computer interaction control board is implemented with a 32-bit STM32F107VCT6 single-chip microcomputer, which are respectively responsible for the motion control tasks and human-computer interaction tasks of the AGV.

[0098] The motion control board is connected with the human-computer interaction control board, motor drive module, navigation module, safety protection module, and power module to complete the AGV motor control, perform information interaction with the human-computer interaction control board, and be ...

Embodiment 2

[0123] The target point includes a series of stops during the AGV walking process. The coding method of the starting point and the stop point is based on the running speed of the AGV. If the south pole of the bar is up, it is 0, and if the north pole is up, it is 1. The AGV starting station and docking station are set according to the binary coding method. When the AGV runs fast, use the North Pole as the starting code to encode the AGV's starting site and stop site by counting the number of consecutive South Pole magnetic stripes, or use the South Pole as the starting code to count the number of consecutive North Pole magnetic stripes Coding of the start site and stop site of the AGV.

[0124] As a preferred embodiment, when the AGV is running at a slow speed, the AGV start station and stop station coding implementation method. The encoding method of the starting point and the stop station adopts k parallel magnetic stripes as a group, the magnetic stripe is 0 when the south...

Embodiment 3

[0130] As a preferred embodiment, when the AGV is running fast, the AGV start station and stop station encoding method is: with the north pole (status code=1) as the start code, by counting the number of consecutive south poles (status code=0) magnetic stripes The number of AGV's start site and stop site coding; or use the south pole (status code = 1) as the start code, by counting the number of consecutive north poles (status code = 0) magnetic stripes to encode the AGV's start site and stop site encoding.

[0131] Preferably, the fast running speed of the AGV means that the linear speed of the AGV is higher than 0.5 m / s and lower than 1.5 m / s, and the angular speed is higher than 0.5 rad / s and lower than 1 rad / s. When the AGV is running fast, the main reason why the encoding method of the start station and the stop station does not use the binary encoding method when the AGV is running slowly is that the interference between the magnetic fields of different poles is easy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com