Mini lamp bead, manufacturing method, backlight source and display equipment

A technology of backlight source and lamp beads, applied in the field of production method, backlight source and display equipment, and mini lamp beads, can solve the problems of increased power, more heat generation, and small luminous angle of MINILED, and achieves reduction of power and heat generation. , the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In order to solve the above technical problems, the present invention provides a mini lamp bead, which can realize side light emission and increase the brightness between lamp beads, thereby expanding the distance between lamp beads and reducing the density of lamp beads on the backlight, thereby reducing cost and power consumption. As an illustration, in the embodiment, the MINI LED lamp bead that appears in the following refers to the miniature lamp bead mentioned above.

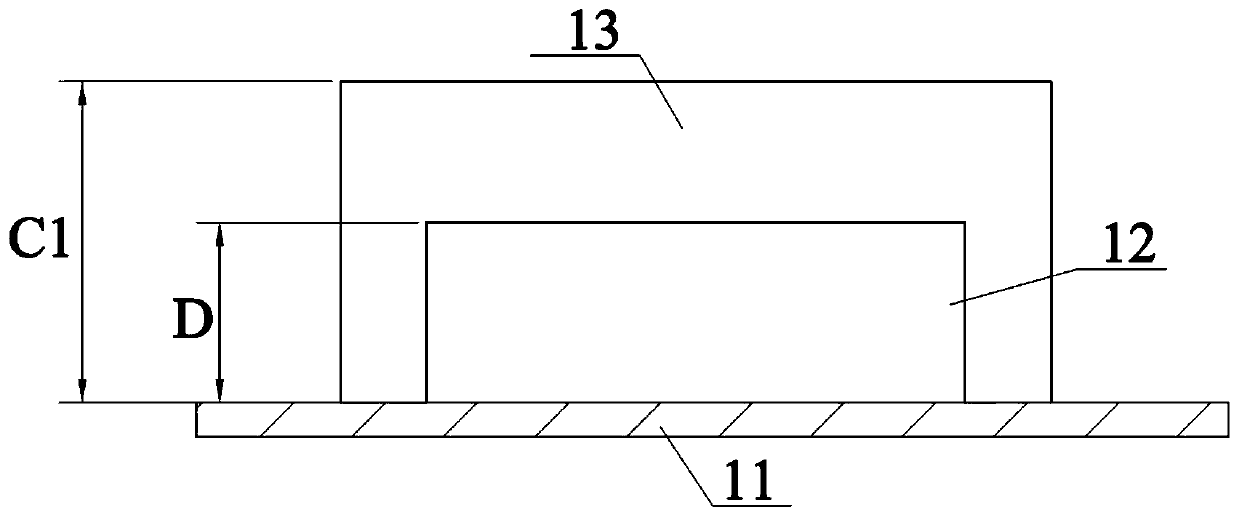

[0051] like Figure 4 As shown, the MINI LED light bead includes a light source 20 and a microlens 24; the microlens 24 surrounds the light source 20; The surface is flush. like Figure 4 The direction shown in is a reference to define up, down, left, right, etc. orientations, which are only used to describe the relative positions of each component, and should not be used as limitations on this application.

[0052] Described microlens 24 is provided with a cavity, and described light emitting so...

Embodiment 2

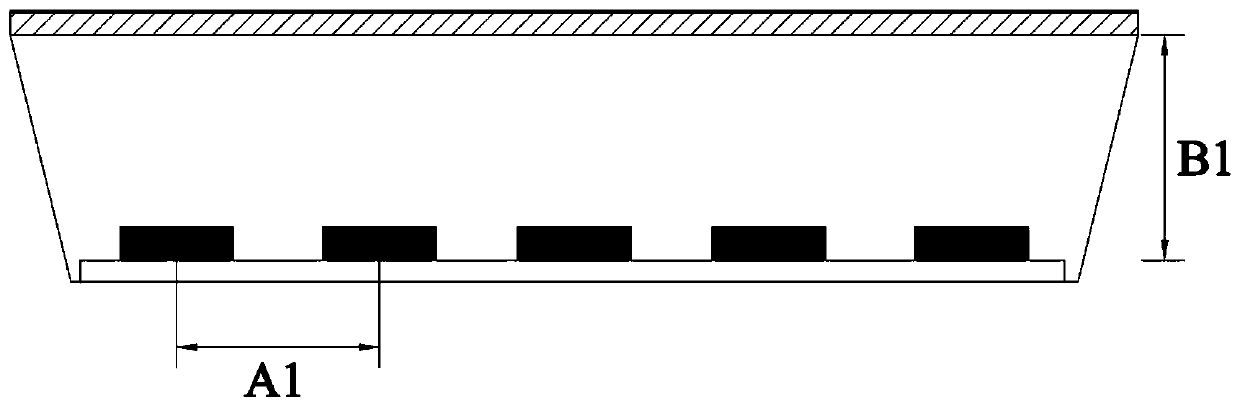

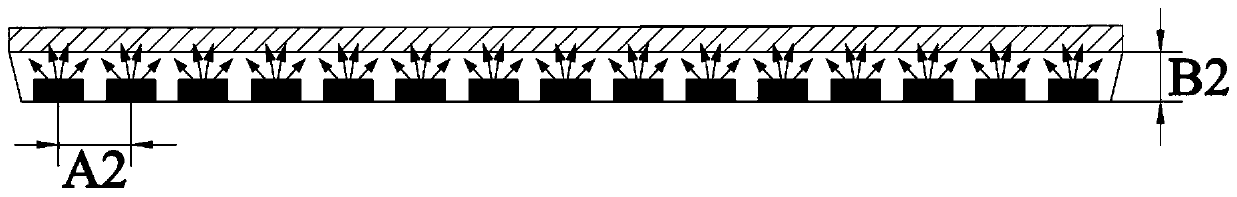

[0081] like Figure 7 As shown, this embodiment provides a backlight source, including a substrate 30 on which the miniature lamp beads (MINI LED lamp beads) are arranged in an array; the substrate 30 is a circuit board.

[0082] The MINI LED lamp beads can realize a large-angle light emitting range of ±70°, increasing the light energy between the MINI LED lamp beads. At the same time, the height C2 of the MINI LED lamp beads is about 0.65mm, so that the MINI LED lamp beads have a larger optical distance, thereby increasing the light mixing effect among the MINI LED lamp beads. Therefore, the distance A3 between the MINI LED lamp beads on the backlight of the present application can be about 10mm, and then the density of the MINI LED lamp beads on the substrate 30 can be reduced, and the number of MINI LED lamp beads in the backlight source of the present application per unit area can be reduced. Compared with the traditional backlight, the number of MINI LED lamp beads can b...

Embodiment 3

[0085] This embodiment provides a display device, including a display panel, an optical component, and the backlight source. The optical component is disposed between the display panel and the backlight source. The light generated by the backlight source is irradiated on the display panel after passing through the optical assembly, so as to form an image on the display panel.

[0086] In the display device of the present application, the density of MINI LED lamp beads on the backlight source is small; in use, energy consumption and heat generation can be reduced, thereby ensuring the normal operation of the backlight source, thereby ensuring that the display device can image normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com