Emulsified nanometer fatty powder and preparation method and application thereof

A kind of fat powder and nanotechnology, which is applied in the direction of application, animal feed, additional food elements, etc., can solve the problems of difficult application in animal husbandry industry, immature nanotechnology, unbalanced fatty acid structure, etc., to improve the production performance of livestock and poultry, Improve absorption utilization rate and production performance, good storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

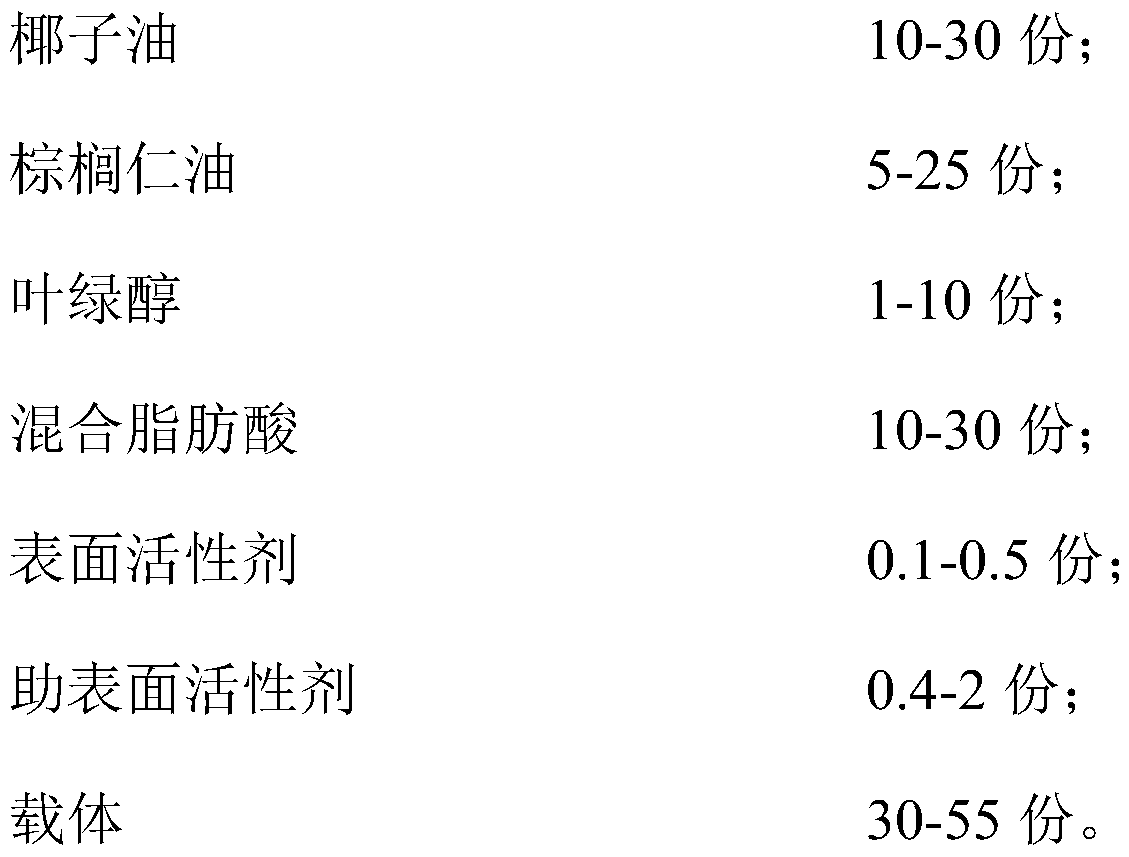

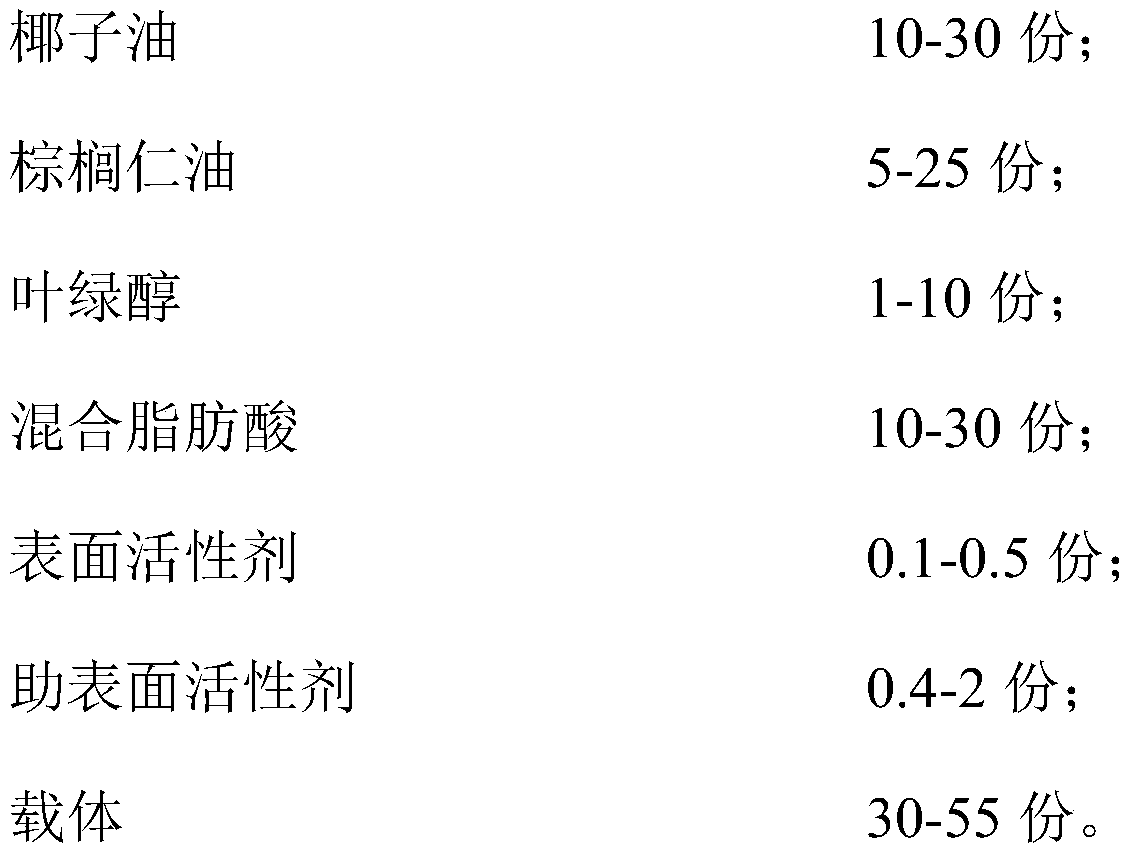

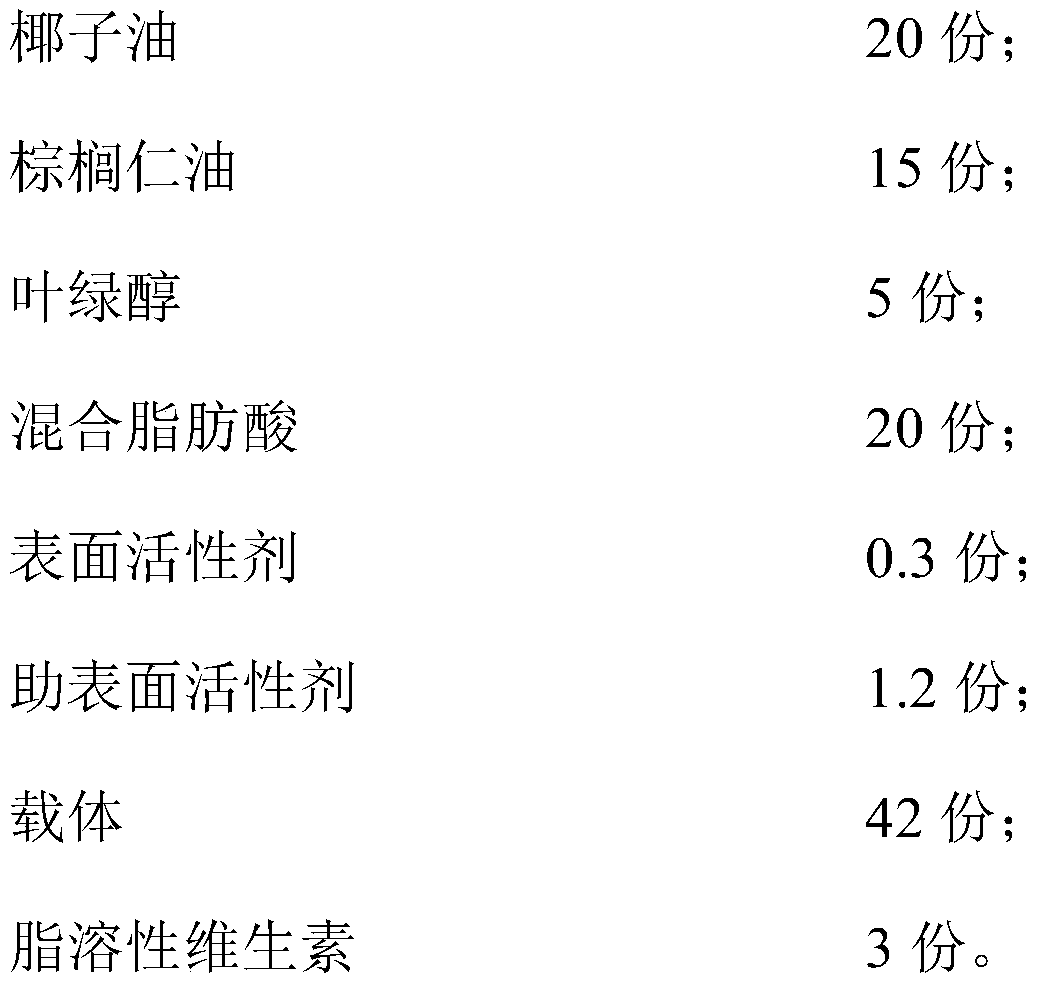

[0049] A kind of emulsified nano fat powder, by weight, is made up of following components:

[0050]

[0051] Among them, the mixed fatty acid is a combination of capric acid and linoleic acid with a mass ratio of 2:1, the mass ratio of Ω6 to Ω3 is 4:1, the surfactant is lysolecithin, the co-surfactant is n-butanol, and the carrier It is corn germ meal, and the fat-soluble vitamin is VE.

[0052] The preparation method is:

[0053] (1) Coconut oil and palm kernel oil are mixed and heated to 70°C, then mixed with phytol, mixed fatty acids and fat-soluble vitamins and stirred until all substances are completely dissolved to obtain an oil phase, and the surfactant and co-surfactant are mixed in Disperse and dissolve in water, the temperature is 60°C, the volume ratio of the total volume of surfactant and co-surfactant to water is 1:100, and the water phase is obtained;

[0054] (2) Mix the oil phase and the water phase, and then continue to heat up to 85°C for an average of ...

Embodiment 2-5

[0058] The difference with Example 1 is that in this example, the mass ratio of the linoleic acid to capric acid is 1.5:1 (Example 2), 2.8:1 (Example 3), 1.2:1 (Example 3). 4), 3:1 (embodiment 5).

Embodiment 6-8

[0060] The difference from Example 1 is that in this example, the mass ratio of Ω6 to Ω3 is 3:1 (Example 6), 2:1 (Example 7), and 5:1 (Example 8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com