Invar alloy and continuous casting production method thereof

A technology of Invar alloy and production method, applied in the field of Invar alloy and its continuous casting production, can solve the problems of decreased strain resistance, easy occurrence of hot cracks on the surface, large temperature difference between the billet shell and the core, etc., so as to improve the tensile strength. Stress capacity, reduced crack susceptibility, effect of reduced cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The vertical bending continuous casting machine is used for the production method of Invar alloy continuous casting. The arc radius of the casting machine is 8000mm, the length of the vertical section is 2510mm, and the metallurgical length is 27600mm. The length of the slab is 9800mm, the width is 1260mm, and the thickness of the slab is 220mm. When smelting Invar alloy, the composition is controlled as follows by weight percentage: C: ≤0.05%, Si: ≤0.30%, Mn: 0.20-0.60%, P≤0.020%, S≤0.010%, Ni: 35.0-37.0% .

[0053] In the smelting stage of the converter, the phosphorus content in the molten steel and slag is reduced by slag removal or slag blocking after the furnace, wherein the phosphorus content in the outbound converter is reduced to below 0.003% (weight). The LF refining stage increased the reduction time to reduce the sulfur content to 0.001% by weight.

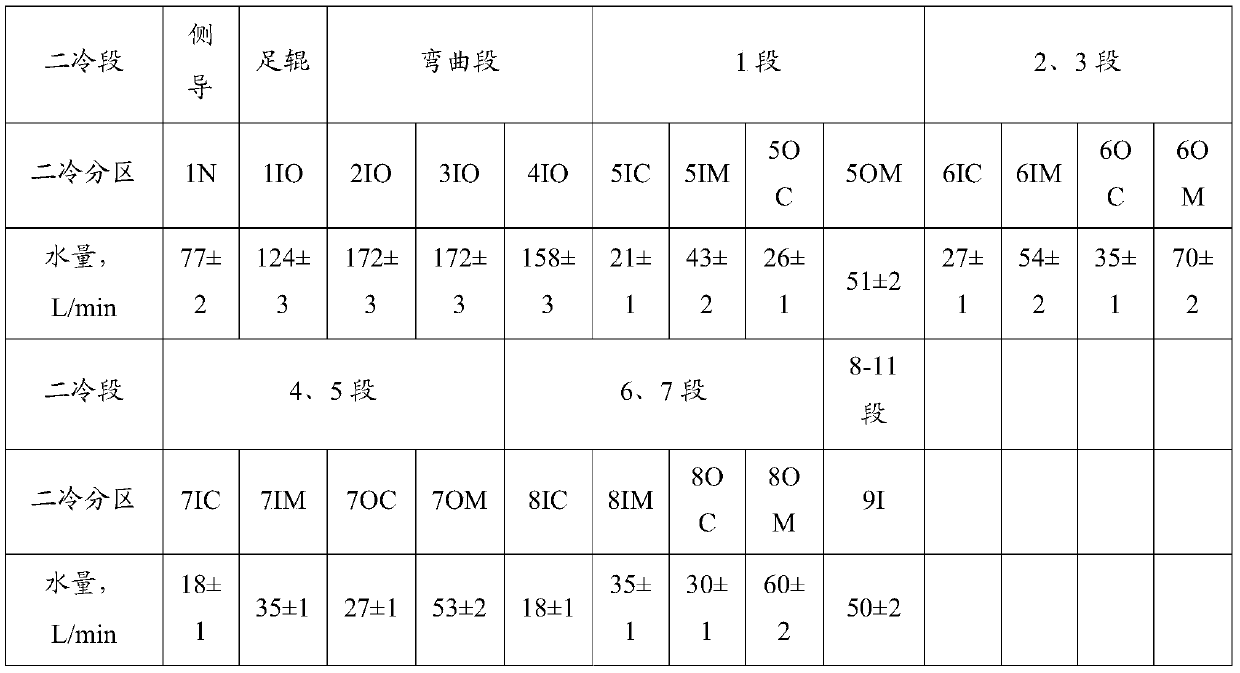

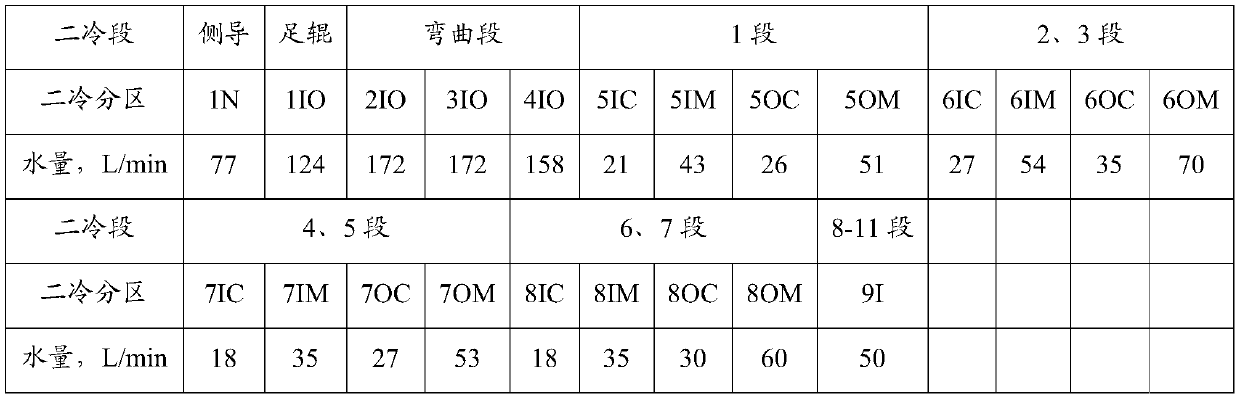

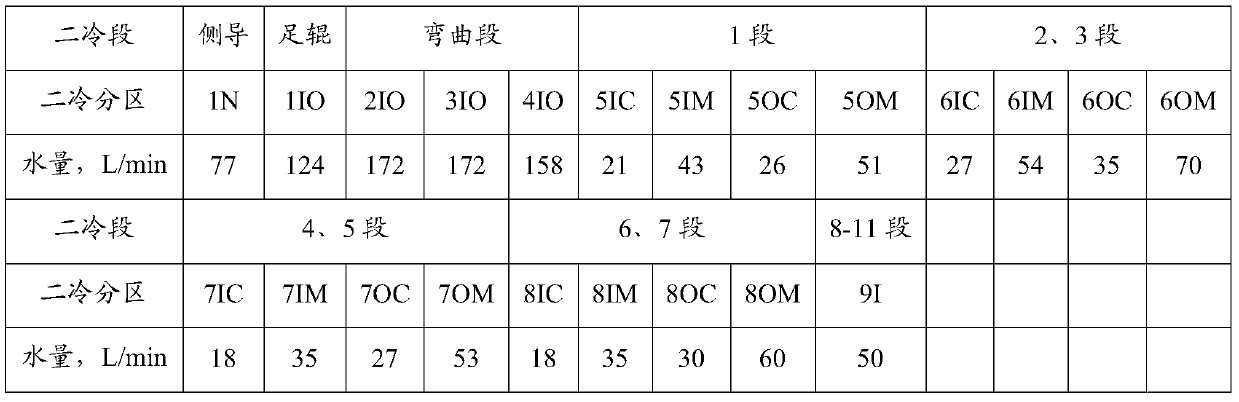

[0054] Control the cooling water flow rate of the crystallizer to 200-260m during the pouring stage 3 / h; ...

Embodiment 2

[0060] The vertical bending continuous casting machine is used for the production method of Invar alloy continuous casting. The arc radius of the casting machine is 8000mm, the length of the vertical section is 2510mm, and the metallurgical length is 27600mm. The length of the slab is 9800mm, the width is 1260mm, and the thickness of the slab is 220mm. When smelting Invar alloy, the composition is controlled as follows by weight percentage: C: ≤0.05%, Si: ≤0.30%, Mn: 0.20-0.60%, P≤0.020%, S≤0.010%, Ni: 35.0-37.0% .

[0061] In the smelting stage of the converter, the phosphorus content in the molten steel and slag is reduced by slag removal or slag blocking after the furnace, wherein the phosphorus content in the outbound converter is reduced to below 0.003% (weight). The LF refining stage increased the reduction time to reduce the sulfur content to 0.001% by weight.

[0062] Control the cooling water flow of the crystallizer to 240~260m in the pouring stage 3 / h; the emerg...

Embodiment 3

[0068] The vertical bending continuous casting machine is used for the production method of Invar alloy continuous casting. The arc radius of the casting machine is 8000mm, the length of the vertical section is 2510mm, and the metallurgical length is 27600mm. The length of the slab is 9800mm, the width is 1260mm, and the thickness of the slab is 220mm. When smelting Invar alloy, the composition is controlled as follows by weight percentage: C: ≤0.05%, Si: ≤0.30%, Mn: 0.20-0.60%, P≤0.020%, S≤0.010%, Ni: 35.0-37.0% .

[0069] In the smelting stage of the converter, the phosphorus content in the molten steel and slag is reduced by slag removal or slag blocking after the furnace, wherein the phosphorus content in the outbound converter is reduced to below 0.003% (weight). The LF refining stage increased the reduction time to reduce the sulfur content to 0.001% by weight.

[0070] Control the cooling water flow rate of the crystallizer to 200-230m during the pouring stage 3 / h; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com