A hot continuous rolling production method of thick specification x70 pipeline steel coil

A production method and steel coil technology, applied in metal rolling, metal rolling, workpiece heating devices, etc., can solve problems such as surface scratches, rolling instability, etc., to eliminate loose coils and ensure the exit temperature of rolling , Reduce the effect of left and right movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

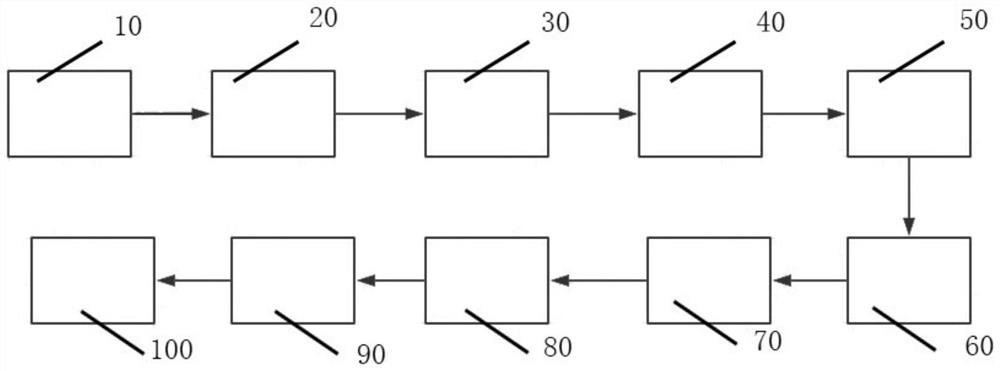

[0048] The slab transport device 10 is transported in the heating furnace 20 to the heating furnace 20, the heating furnace 20 having a number of ≥ 10 blocks, the After the opening of the rolling transition material, after the heating furnace 20, a slab (naturally cooled) of a temperature below 300 ° C is then transported to the heating furnace 20.

[0049]In step one, the steel temperature is controlled below 300 ° C, and the purpose is to prevent the heat stress of the steel blank to generate thermal cracks. Before the billet enters the heating furnace 20, it is first loaded into the open-rolled transduction material, and the number is specified to be ≥10 blocks. It is an object to be a hot roller, a preheated roll, which makes the roll in a preferred state, improve the rolling line. Stability of finishing rolling rolling during steel. After the heating of the heating furnace 20, when the furnace is released, the temperature difference of the same plate is within 20 ° C and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com