All-solid-state structure fluorotellurite glass optical fiber with dispersion close to zero and flatness, preparation method and application thereof

A technology of fluorotellurite and glass optical fiber, which is applied in the preparation and generation of mid-infrared optical frequency combs. In the field of all-solid-state structure fluorotellurite glass optical fiber, it can suppress the occurrence of SBS effect, and the repetition frequency can be tuned in a wide range. Reduce the effect of drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

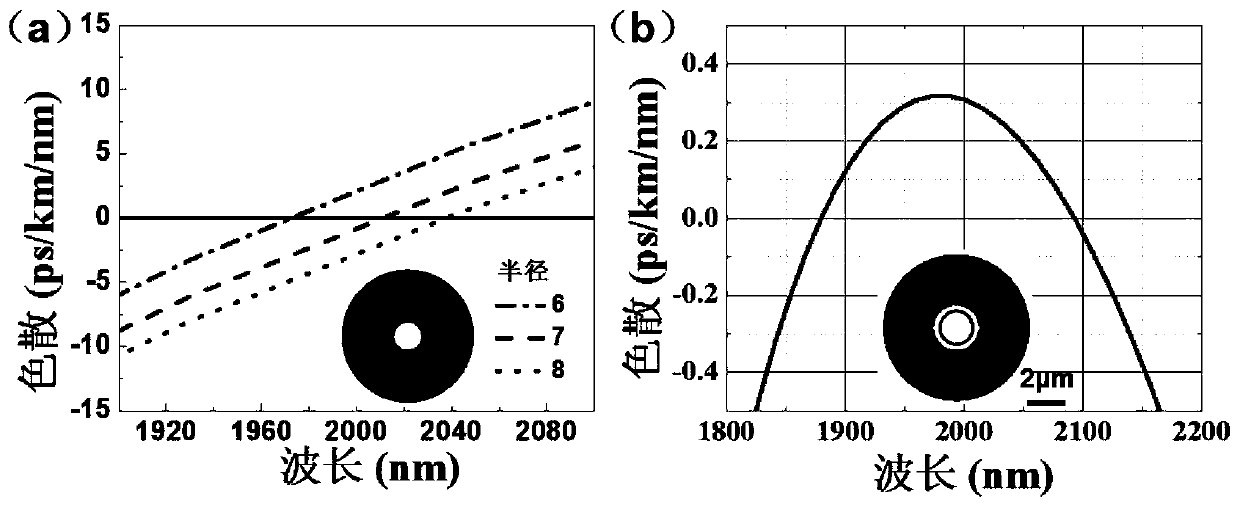

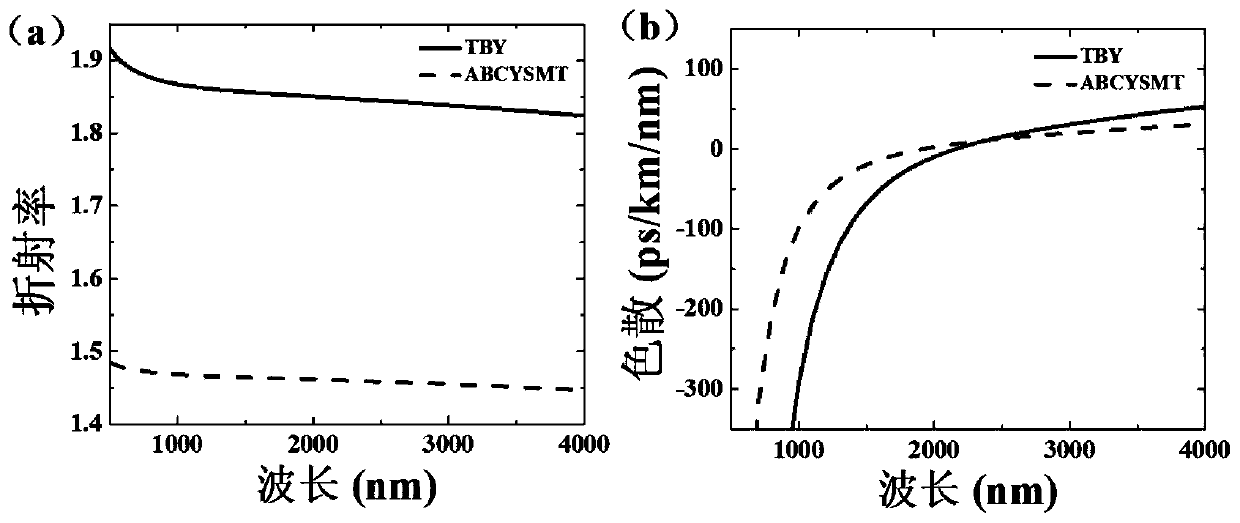

[0035] An all-solid-state fluorotellurite glass optical fiber with nearly zero dispersion and flat structure. The optical fiber consists of a high-refractive-index glass core, a low-refractive-index annular glass layer, a high-refractive-index annular glass layer, and a low-refractive-index glass from the inside to the outside. The composition of the outer cladding, the cross-section of the fiber is as figure 1 (b) shown in the illustration; wherein, the material of the high refractive index glass core and the high refractive index annular glass layer is 70TeO 2 -20BaF 2 -10Y 2 o 3 (TBY mixture), the material of the low refractive index annular glass layer and the low refractive index glass outer cladding is 33AlF 3 -9BaF 2 -17CaF 2 -12YF 3 -8SrF 2 -11MgF 2 -10TeO 2 (ABCYSMT compound), the refractive index curves of TBY glass and ABCYSMT glass can be found in figure 2 (a). Among them, the refractive index of the TBY compound is about 1.82-1.95, and the refractive i...

Embodiment 2

[0039] A method for preparing an all-solid structure fluorotellurite glass optical fiber with near-zero flat dispersion, the specific steps are as follows:

[0040] Step 1: Preparation of high refractive index glass core:

[0041] Weigh 30-50g of TBY mixture and melt it into glass liquid at 900-1100°C. During the melting process, carry out in a nitrogen-protected glove box. After complete melting, clarify for 30-60 minutes, pour the molten TBY glass liquid into the Heat it into a barrel-shaped mold at 200-400°C, then move it to a muffle furnace that has been preheated to 300-500°C for 3 hours, and then lower it to room temperature to obtain a TBY glass core rod, which is precision ground and polished , make a TBY glass rod with a diameter of 5-10 mm, and set it aside;

[0042] Step 2: Preparation of low refractive index ring glass layer:

[0043] Weigh 40-80g of ABCYSMT mixture and melt it into glass liquid at 900-1100℃. During the melting process, carry out in a nitrogen-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com