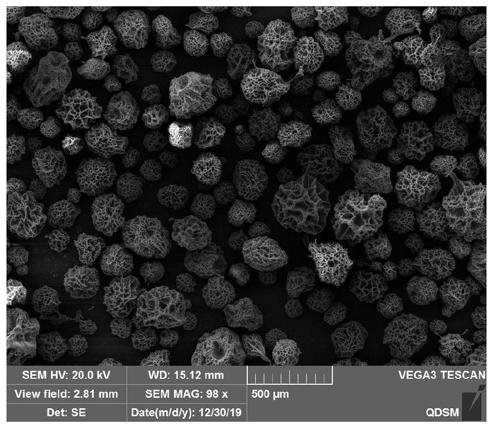

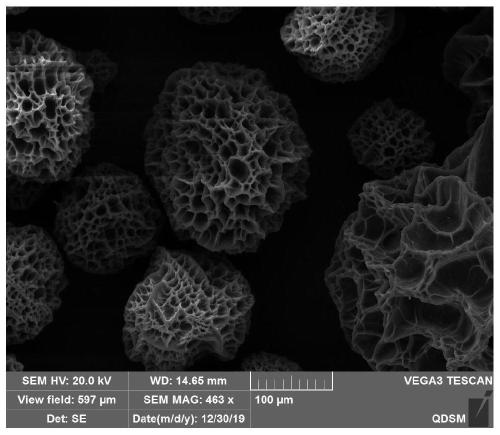

Highly porous gelatin microsphere

A technology of microspheres and gelatin, applied in medical science, prostheses, etc., can solve the problems of slow degradation of gelatin microspheres affecting applications, low surface ratio, and low elasticity, and achieve good biocompatibility, strong plasticity, and beneficial technology effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: 3g of gelatin type A and 20ml of double distilled water were mixed in a 250ml beaker, and dissolved in an oven at 55°C for 30min. Mix the mixture thoroughly. Slowly pour the mixture into a 250ml beaker containing 60ml paraffin oil and 20ml edible oil, stir on a stirrer at 700r / min, 55°C, 30min. After 30 minutes, stop stirring, quickly place the 250ml beaker directly in the center of the 2000ml beaker, continue to stir on the stirrer, and at the same time put ice on the periphery, cool down to cool the microspheres, 700r / min, 30min. Let stand for 5min. At this time, the microsphere and the oil are delaminated, and the oil is poured out, because there is still a large amount of oil around the microsphere, then it is poured into a 150 mesh sieve, and a large amount of oil around the microsphere is washed away with 20ml dioxane, and then Transfer the microspheres in the sieve to a 250ml beaker containing 10ml of dioxane and soak for 30min, pour off the dioxane,...

Embodiment 2

[0016] Example 2: Mix 2g of gelatin type A and 20ml of double distilled water in a 250ml beaker, and dissolve in an oven at 55°C for 30min. Mix the mixture thoroughly. Slowly pour the mixture into a 250ml beaker containing 60ml paraffin oil and 20ml edible oil, stir on a stirrer at 700r / min, 55°C, 30min. After 30 minutes, stop stirring, quickly place the 250ml beaker directly in the center of the 2000ml beaker, continue to stir on the stirrer, and at the same time put ice on the periphery, cool down to cool the microspheres, 700r / min, 30min. Let stand for 5min. At this time, the microsphere and the oil are delaminated, and the oil is poured out, because there is still a large amount of oil around the microsphere, then it is poured into a 150 mesh sieve, and a large amount of oil around the microsphere is washed away with 20ml dioxane, and then Transfer the microspheres in the sieve to a 250ml beaker containing 10ml of dioxane and soak for 30min, pour off the dioxane, add 10m...

Embodiment 3

[0017] Embodiment 3: same as embodiment 1, the number of revolutions is changed to 600r / min, 800r / min, 900r / min to prepare gelatin microspheres with different particle sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com