Graphene melt-blown fabric, manufacturing process and protective article thereof

A technology of manufacturing technology and protective equipment, which is applied in the field of forming and post-processing of melt blown cloth, which can solve the problems of low hygiene level and complex fiber composition, and achieve the effect of easy manufacturing and good adsorption and filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

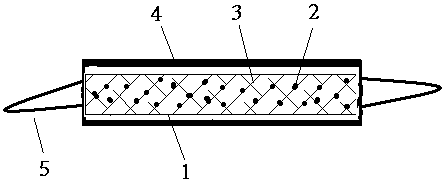

[0032] Such as figure 1 The graphene melt-blown cloth mask shown is a composite fabric made of polypropylene melt-blown cloth as the middle layer and two layers of non-woven fiber cloth as the upper and lower layers. It is cut and stitched (ironing), and then two ear straps are bonded together. . Graphene powder is scattered and adhered in the polypropylene melt-blown fiber, and the adhesion is that the graphene powder particles are partially embedded in the melt-blown cloth fiber, or the graphene powder is bonded on the surface of the melt-blown cloth fiber.

[0033] Graphene melt-blown cloth molding adopts the following process:

[0034] 1) Add graphene spraying equipment between the 0.5mm flat outlet of the melt-blown cloth and melt-blown fiber equipment and the cooling equipment;

[0035] 2) The melt-blown cloth is sprayed and melted into flocculent or reticular fibers, and when it is still in a state of high-temperature viscous flow, spray graphene powder (nano-scale pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com