Fuel cell air peroxide ratio and flow pressure cooperative control method and system

An air peroxygen ratio, fuel cell technology, applied in the direction of fuel cell control, fuel cell, fuel cell additives, etc., can solve the problems of only considering, failing to effectively control pressure, not considering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

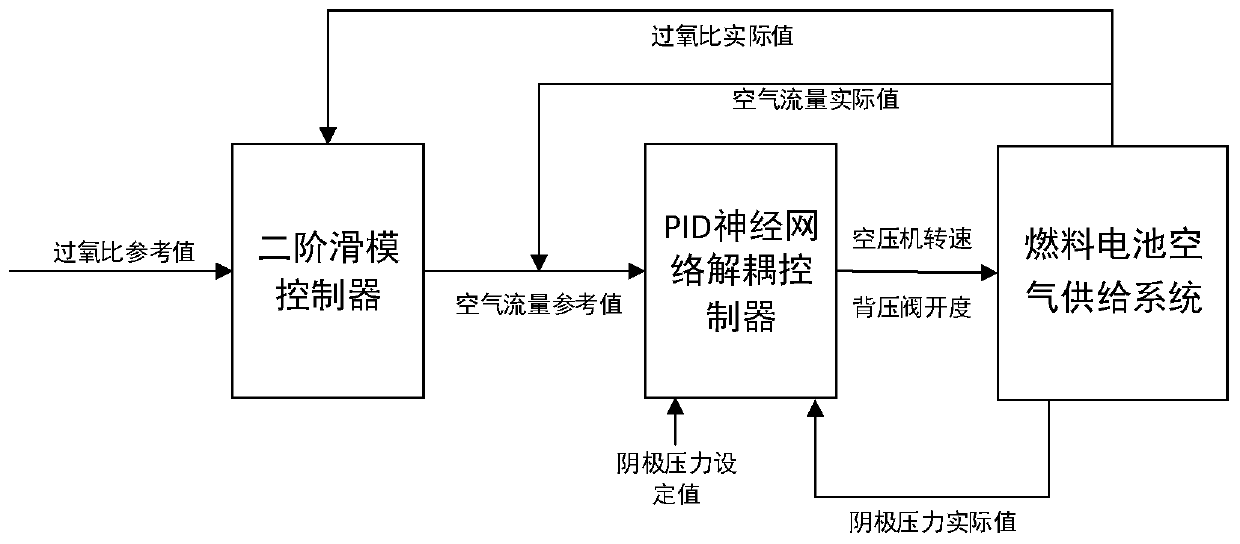

[0130] A fuel cell air oxygen ratio and flow pressure cooperative control method, such as figure 1 and figure 2 ,include:

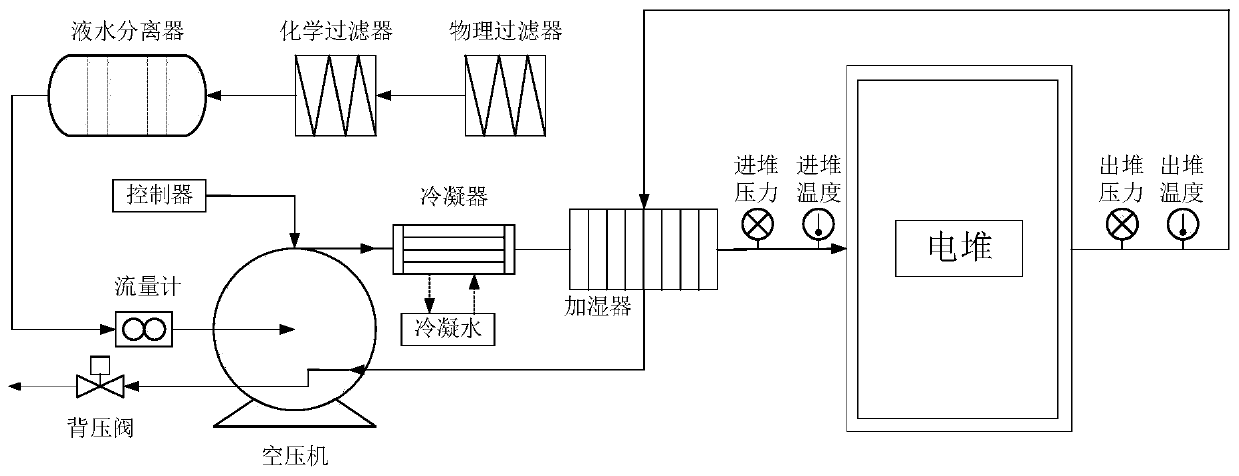

[0131] Experiments are carried out through the fuel cell air supply system, and the actual measurement obtains the reference value of the peroxygen ratio The actual value of the air flow and the actual value of the cathode pressure of the fuel cell are respectively detected by the air flow meter and the pressure sensor, and the set value of the cathode pressure is input;

[0132] The fuel cell air compressor speed and back pressure valve opening are controlled by a second-order sliding mode controller and a PID neural network decoupling controller. The specific steps are as follows:

[0133] 1) Will Compared with the actual value of peroxygen The difference is input into the second-order sliding mode controller to obtain the air flow reference value;

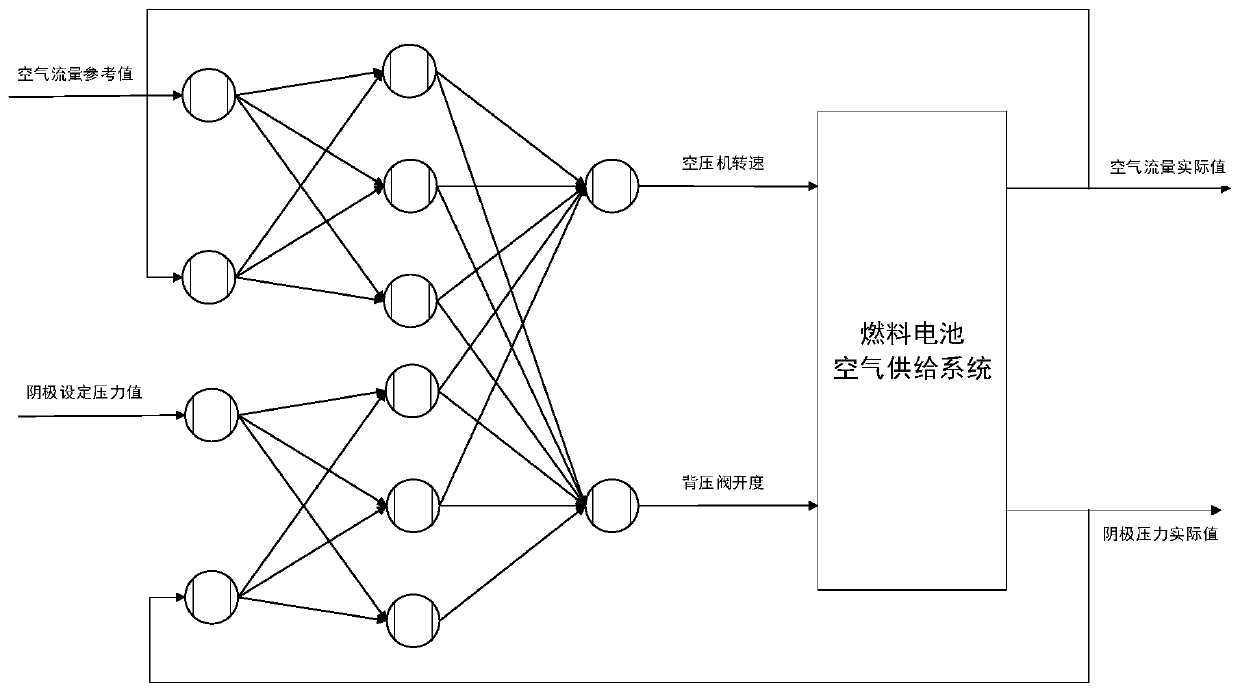

[0134] 2) Input the air flow reference value, air flow actual value, cathode pressure set value...

Embodiment 2

[0188] A fuel cell air oxygen ratio and flow pressure cooperative control system, comprising:

[0189] The simulation verification module is used to establish the simulation model of the fuel cell air supply system and use the model to conduct experiments to obtain the reference value of the oxygen ratio

[0190] sliding mode control module for the Compared with the actual value of peroxygen The difference is input into the second-order sliding mode controller to obtain the air flow reference value;

[0191] The decoupling control module is used to input the air flow reference value, air flow actual value, cathode pressure set value and cathode pressure actual value into the PID neural network decoupling controller, and output the speed of the air compressor and the opening of the back pressure valve;

[0192] Among them, the fuel cell air supply system simulation model is built based on Matlab Simulink and includes cathode gas dynamic model, air compressor dynamic model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com