A kind of preparation method of fiber skeleton fuel cell proton exchange membrane

A proton exchange membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as easy to evaporate water, difficult to keep moisture, easy to be damaged by swelling, etc., to improve high temperature working stability, improve water retention, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

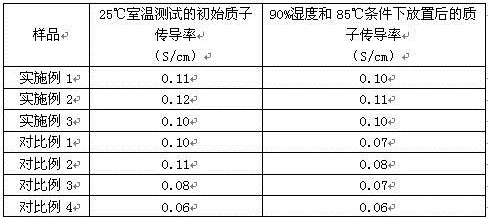

Examples

Embodiment 1

[0030] (1) Clean the continuous glass fiber with a diameter of 20-30 μm with a sodium hydroxide solution with a mass concentration of 3% to clean and activate the surface of the inorganic fiber, and dry it at 100°C for later use;

[0031] (2) Carding the glass fiber treated in step (1) and the sulfonated polyarylether nitrile ketone fiber with a diameter of 10-20 μm at a mass ratio of 1:3 using a conventional fiber carding machine, and laying and crossing to form a mesh;

[0032] (3) Spray a layer of Nafion solution with a mass concentration of 5% on the mesh cloth obtained in step (2), and the spraying amount is 10% of the total mass of the mesh cloth, so that the Nafion solution fully penetrates the mesh cloth, and then sprays it with aluminum chloride solution , ammonia solution, and silica airgel, the dispersion liquid is an aluminum chloride solution with a mass concentration of 8%, ammonia solution with a mass concentration of 3%, and silica airgel at a mass ratio of 1:3:...

Embodiment 2

[0035] (1) Clean the continuous glass fiber with a diameter of 20-30 μm with a sodium hydroxide solution with a mass concentration of 3% to clean and activate the surface of the inorganic fiber, and dry it at 100°C for later use;

[0036] (2) Comb the glass fiber treated in step (1) and the sulfonated polyether ether ketone fiber with a diameter of 10-20 μm at a mass ratio of 1:4 using a conventional fiber carding machine, and lay the net to cross into a net;

[0037](3) Spray a layer of Nafion solution with a mass concentration of 5% on the mesh cloth obtained in step (2), and the spraying amount is 15% of the total mass of the mesh cloth, so that the Nafion solution fully penetrates the mesh cloth, and then sprays it with aluminum chloride solution , ammonia solution, and silica airgel, the dispersion liquid is an aluminum chloride solution with a mass concentration of 8%, ammonia solution with a mass concentration of 3%, and silica airgel at a mass ratio of 1:3:3 It is disp...

Embodiment 3

[0040] (1) Clean the continuous glass fiber with a diameter of 20-30 μm with a sodium hydroxide solution with a mass concentration of 5% to clean and activate the surface of the inorganic fiber, and dry it at 100°C for later use;

[0041] (2) Carding the glass fiber treated in step (1) and the sulfonated polyarylether nitrile ketone fiber with a diameter of 10-20 μm in a mass ratio of 1:3 with conventional fiber carding, and laying and crossing to form a mesh;

[0042] (3) Spray a layer of Nafion solution with a mass concentration of 5% on the mesh cloth obtained in step (2), and the spraying amount is 15% of the total mass of the mesh cloth, so that the Nafion solution fully penetrates the mesh cloth, and then sprays it with aluminum chloride solution , ammonia solution, and silica airgel, the dispersion liquid is an aluminum chloride solution with a mass concentration of 8%, ammonia solution with a mass concentration of 3%, and silica airgel at a mass ratio of 1:3:3 It is di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com