Rabbit hair keratin antibacterial gel and preparation method thereof

A protein gel, keratin technology, applied in the fields of biochemical fiber treatment, medical science, absorbent pads, etc., can solve the problems of small molecular weight, oxidative breakage of peptide chains, low quality, etc., and achieve the effect of good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

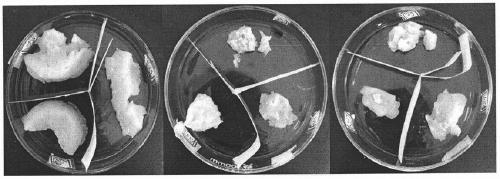

[0057] Taking the concentration of carboxymethyl chitosan as a variable, weigh 1 part of carboxymethyl chitosan powder into a beaker, add distilled water to 100 parts, stir with a glass rod until it is completely dissolved, and configure it with a mass fraction of 1%. carboxymethyl chitosan solution. Add 15 parts of rabbit hair keratin powder into the solution, then add L-cysteine accounting for 1.5% of the protein content, and stir with a glass rod until the keratin powder is completely suspended in the carboxymethyl chitosan solution. Carried out the antibacterial property test of 3 concentration gradients, are respectively 10 -2 、10 -3 、10 -4 , which has the effect of Figure 7 shown.

Embodiment 2

[0059] Take by weighing 3 parts of carboxymethyl chitosan powder in the beaker, add distilled water to 100 parts, stir with a glass rod until fully dissolved, and configure a mass fraction of 3% carboxymethyl chitosan solution. Add 15 parts of rabbit hair keratin powder into the solution, then add L-cysteine accounting for 1.5% of the protein content, and stir with a glass rod until the keratin powder is completely suspended in the carboxymethyl chitosan solution. Carried out the antibacterial property test of 3 concentration gradients, are respectively 10 -2 、10 -3 , 10 -4 , which has the effect of Figure 8 shown.

Embodiment 3

[0061] Take by weighing 5 parts of carboxymethyl chitosan powder in the beaker, add distilled water to 100 parts, stir with a glass rod until fully dissolved, and configure a mass fraction of 5% carboxymethyl chitosan solution. Add 15 parts of rabbit hair keratin powder into the solution, then add L-cysteine accounting for 1.5% of the protein content, and stir with a glass rod until the keratin powder is completely suspended in the carboxymethyl chitosan solution. Carried out the antibacterial property test of 3 concentration gradients, are respectively 10 -2 、10 -3 , 10 -4 , which has the effect of Figure 9 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com