Interior wall putty with mildew-proof function and preparation method thereof

A kind of interior wall putty and functional technology, applied in the direction of filling slurry, etc., can solve the problems of poor stability, unscientific anti-mildew principle, easy to be affected by moisture and deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing an interior wall putty with anti-mildew function, comprising steps

[0023] (1) Accurately weigh the raw materials of inorganic gelling material, organic additive, cellulose ether, water-repellent, anti-fungal agent, defoamer, and film-forming agent according to the mixing ratio, and pre-mix together to obtain a pre-mixed small material for future use. It can be prepared by conventional mixing equipment in the factory, or directly mixed with barrels and sticks at the construction site.

[0024] (2) According to the formula requirements, accurately weigh the heavy calcium powder with the required mesh size, add the premixed small material, and stir for 10-30 minutes until the mixture is uniform to obtain the interior wall putty with anti-mildew function .

[0025] The present invention also provides an interior wall putty with anti-mildew function, which includes, by mass and proportion, inorganic gelling material: 2-8 parts...

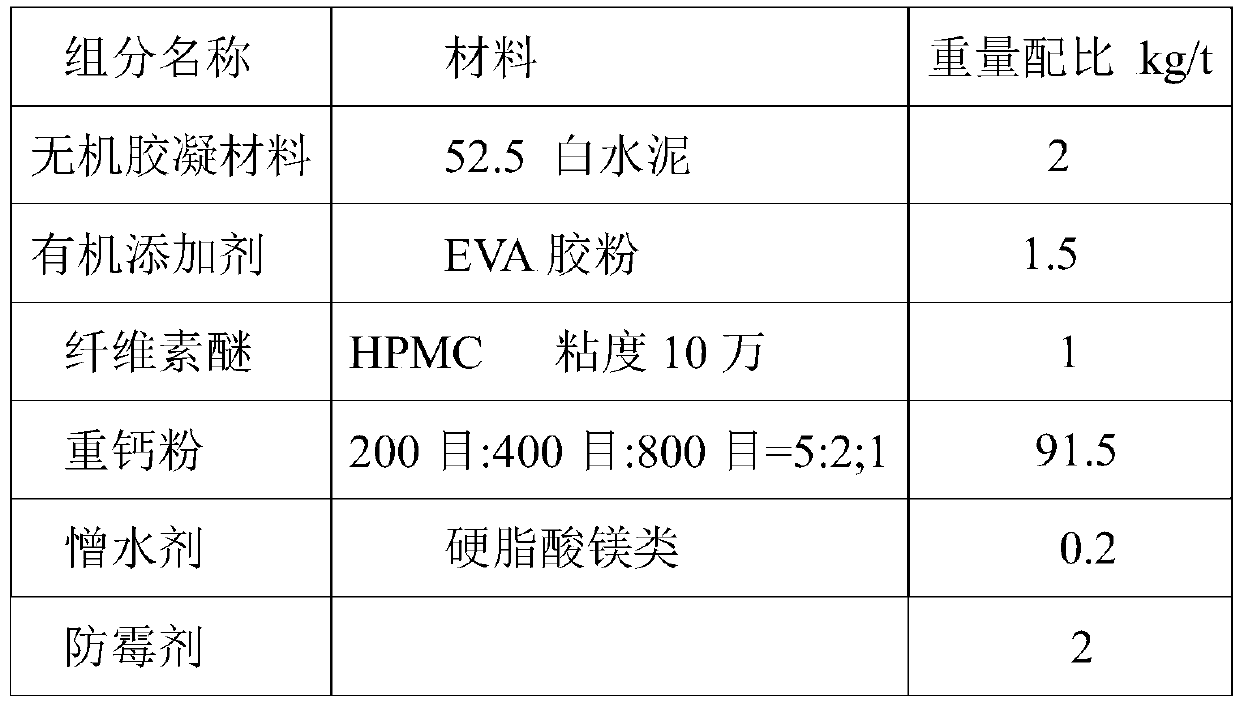

Embodiment 1

[0029]

[0030]

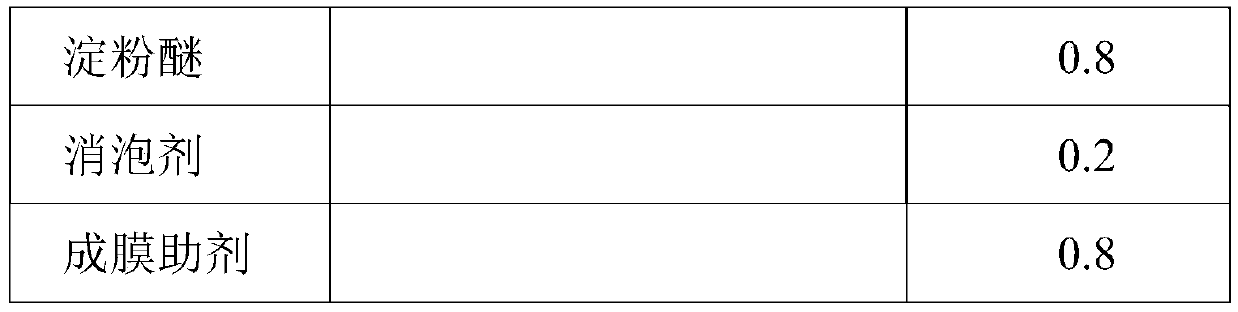

Embodiment 2

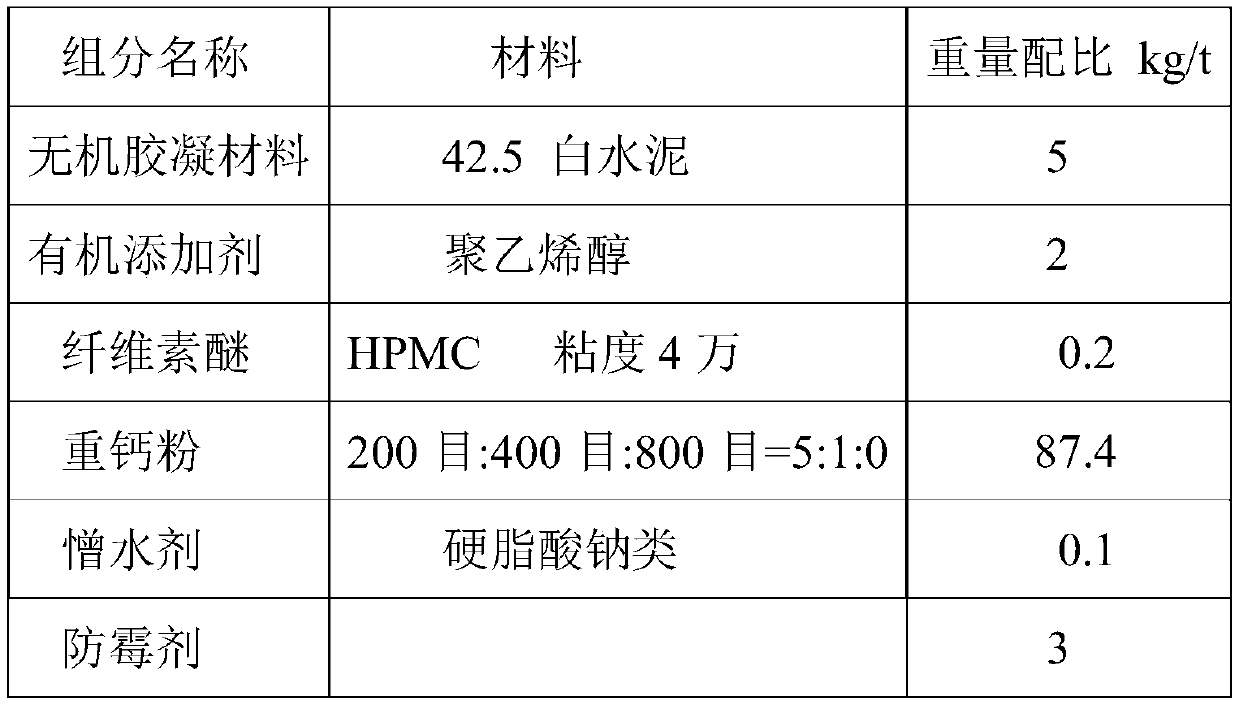

[0032] component name Material Weight ratio kg / t Inorganic gelling material slaked lime 8 organic additives Redispersible latex powder 1 Cellulose ether HPMC viscosity 80,000 0.5 heavy calcium powder 200 mesh: 400 mesh: 800 mesh = 5:1:1 82.9 Hydrophobic agent Magnesium Stearate 0.5 antifungal agent 5 Starch ether 1 Defoamer 0.6 Coalescent 0.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com