Graft-modified high-molecular anti-fog coating, and preparation method and application method thereof

An anti-fog coating, graft modification technology, applied in the direction of coating, can solve the problem of short duration, increase water resistance and durability, good hydrophilicity, and solve the problem of fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

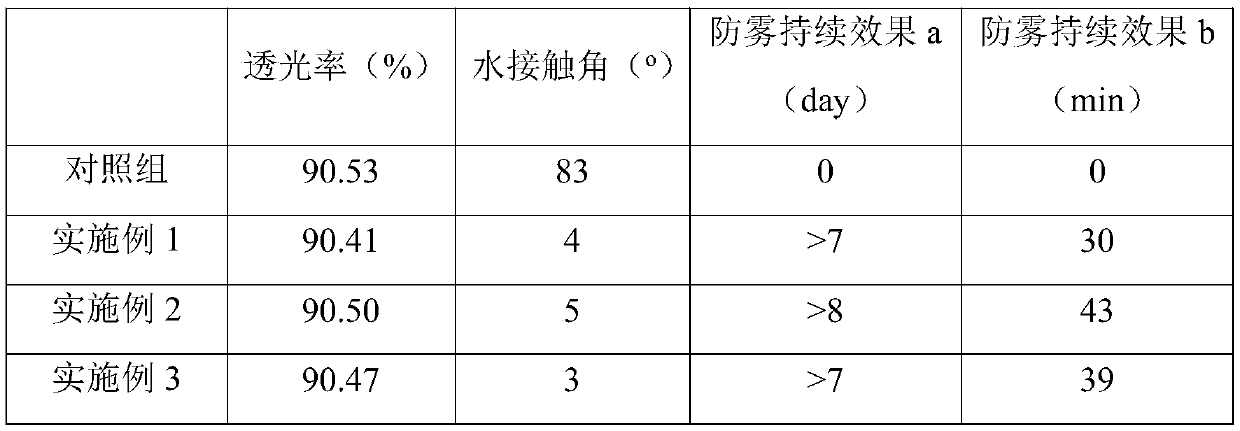

Examples

preparation example Construction

[0037] A preparation method of graft modified macromolecular anti-fog coating, comprising the following steps:

[0038] At 80-95°C, dissolve the long-chain polymer containing polyhydroxyl functional groups into the solvent, then add a metal salt catalyst, add a predetermined proportion of silane according to the controlled grafting rate, and react at 45-65°C for 12- After 24 hours, add nano-titanium dioxide, continue to stir and react for 2-6 hours to obtain the desired product, wherein the grafting rate is 5-50%.

[0039] A method for applying a graft-modified polymer anti-fog coating, comprising the following steps: first cleaning the surface of an article to be treated, then applying the graft-modified polymer anti-fog coating to the surface of the item to be treated, leaving it to dry or heating Drying is sufficient, and the water contact angle on the surface of the article after treatment with the grafted modified polymer anti-fog coating is <10°.

Embodiment 1

[0041] A preparation method of graft modified macromolecular anti-fog coating, comprising the following steps:

[0042] Step 1, preparing a mixed solvent of water and ethanol, wherein the volume ratio of ethanol is 20%;

[0043] Step 2. Dissolve 2g of long-chain polymer polyvinyl alcohol (molecular weight 2500) containing polyhydroxyl functional groups into 50g of the solvent obtained in step 1 at 80°C, then add 0.001g of the metal salt catalyst copper acetate, and add it under stirring. 1 g of silane was reacted at 45° C. for 24 h, then 0.1 g of nano-titanium dioxide was added, and the stirring reaction was continued for 2 h to obtain the desired product with a grafting rate of 50%.

Embodiment 2

[0045] A preparation method of graft modified macromolecular anti-fog coating, comprising the following steps:

[0046] Step 1, prepare mixed solvent, the volume ratio of ethanol is 75%;

[0047] Step 2. Dissolve 20g of long-chain polymer polyvinyl alcohol (molecular weight 10,000) containing polyhydroxy functional groups at 95°C into 100g of the solvent obtained in step 1, then add 0.1g of metal salt catalyst copper acetate, and add 2g of silane was reacted at 65°C for 12h, then 1g of nano-titanium dioxide was added, and the stirring reaction was continued for 2h to obtain the desired product with a grafting rate of 5%.

[0048] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com