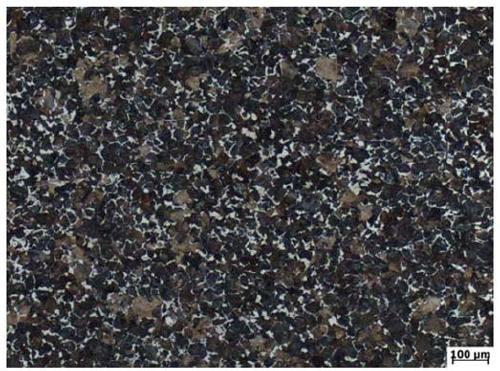

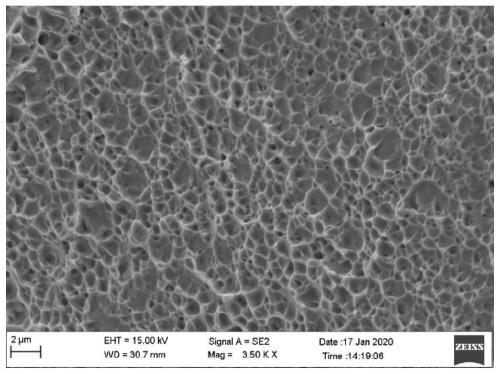

Fine-grain steel for engineering machinery track link section and preparation method thereof

A technology of construction machinery and crawler chains, which is applied in the field of steel metallurgy, can solve problems such as coarse grains, and achieve the effects of fine grains, excellent strength and toughness, and enhanced hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: The implementation steps of the present invention are specifically illustrated by the preparation method of Ф50 specification round steel.

[0042] 1) Converter smelting: The converter uses high-quality molten iron and scrap steel, and the ratio of scrap steel is 10%. When tapping, the slag is left in double gears to prevent oxidative slag from entering the ladle. Add 120kg of ferrochromium, 550kg of ferromanganese, 300kg of silicon-manganese alloy, 50kg of aluminum ingot, 60kg of recarburizer to deoxidize the alloy; 300kg of pre-melted refining slag and 300kg of lime. The tapping temperature is 1610°C, the end point carbon is 0.10%, and the end point phosphorus is 0.009%.

[0043] 2) LF refining: After the ladle enters the station, the LF furnace is heated up to perform slagging and alloy fine-tuning operations. In the early stage, depending on the thinness and thickness of the top slag in the steel, 50kg of lime was added, and ferrosilicon powder, sili...

Embodiment 2

[0049] Embodiment 2: The implementation steps of the present invention are specifically illustrated by the preparation method of Ф70 specification round steel.

[0050] 1) Converter smelting: The converter adopts high-quality molten iron and scrap steel, and the ratio of scrap steel is 8%. When tapping, the slag is left in double gears to prevent oxidative slag from entering the ladle. 120kg of ferrochrome, 550kg of ferromanganese, 300kg of silicon-manganese alloy, 70kg of aluminum ingot, 60kg of recarburizer are added to the steel for deoxidation of the alloy; 300kg of pre-melted refining slag and 300kg of lime. The tapping temperature is 1614°C, the end point carbon is 0.08%, and the end point phosphorus is 0.008%.

[0051] 2) LF refining: After the ladle enters the station, the LF furnace is heated up to perform slagging and alloy fine-tuning operations. In the early stage, depending on the thinness and thickness of the top slag in the steel, 60kg of lime was added, and f...

Embodiment 3

[0057] Embodiment 3: The implementation steps of the present invention are specifically illustrated by the preparation method of Ф40 specification round steel.

[0058] 1) Converter smelting: The converter adopts high-quality molten iron and scrap steel, and the ratio of scrap steel is 9%. When tapping, the slag is left in double gears to prevent oxidative slag from entering the ladle. 120kg of ferrochromium, 550kg of ferromanganese, 300kg of silicon-manganese alloy, 65kg of aluminum ingot, 60kg of recarburizer are added to the steel for deoxidation of the alloy; 300kg of pre-melted refining slag and 300kg of lime. The tapping temperature is 1612°C, the end point carbon is 0.13%, and the end point phosphorus is 0.010%.

[0059] 2) LF refining: After the ladle enters the station, the LF furnace is heated up to perform slagging and alloy fine-tuning operations. In the early stage, depending on the thinness and thickness of the top slag in the steel, 60kg of lime was added, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com