Adsorption film for selectively immobilizing trivalent arsenic, trivalent antimony and tetravalent selenium and preparation method thereof

A selective, trivalent arsenic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems affecting the accuracy of detection and the breadth of application scope, etc., to broaden the pH value range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

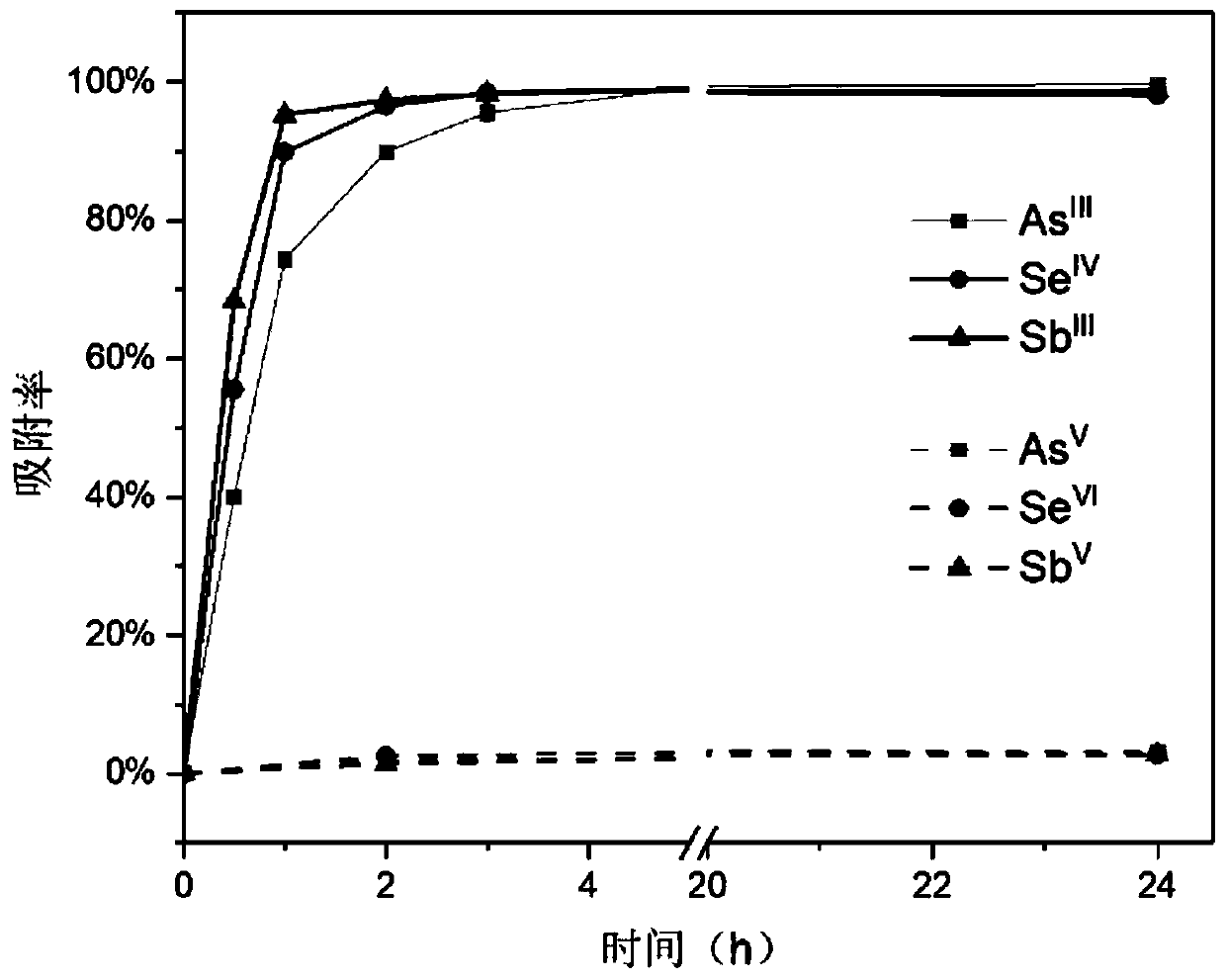

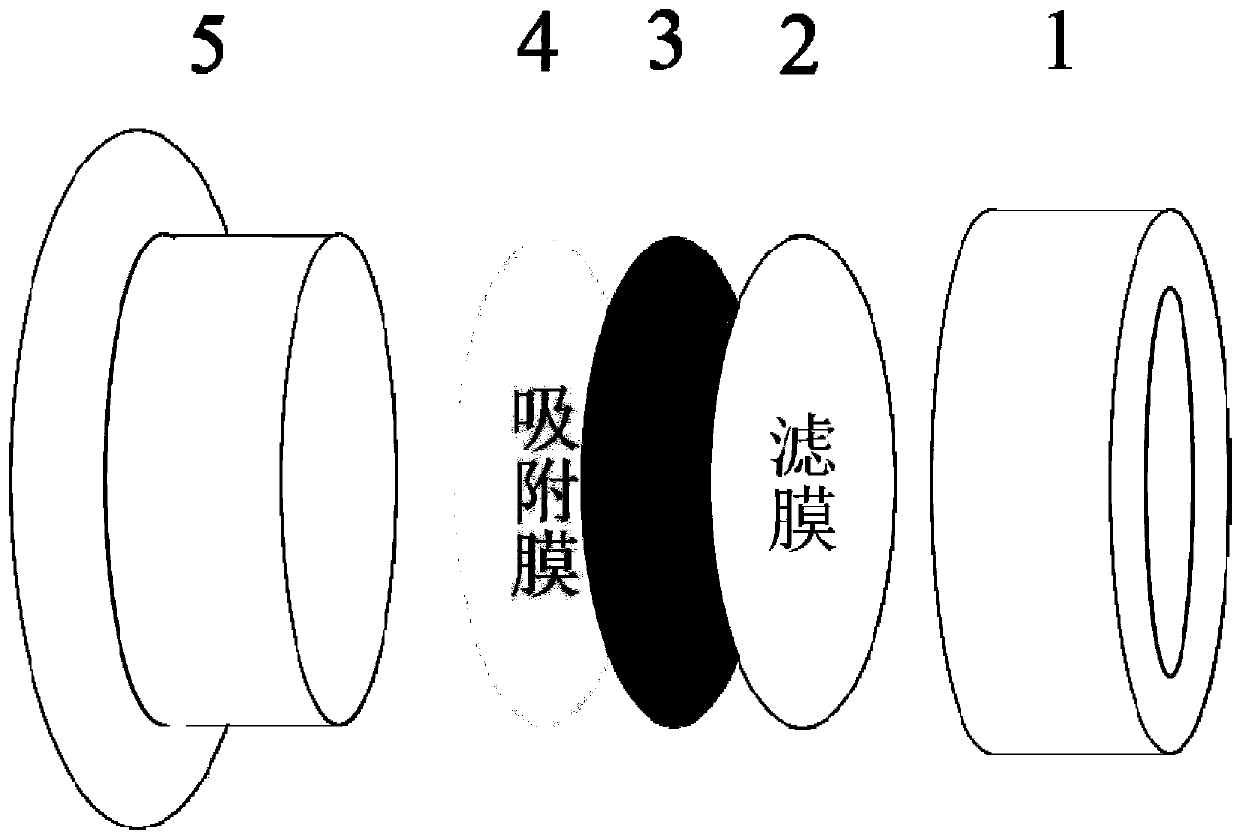

Embodiment 1

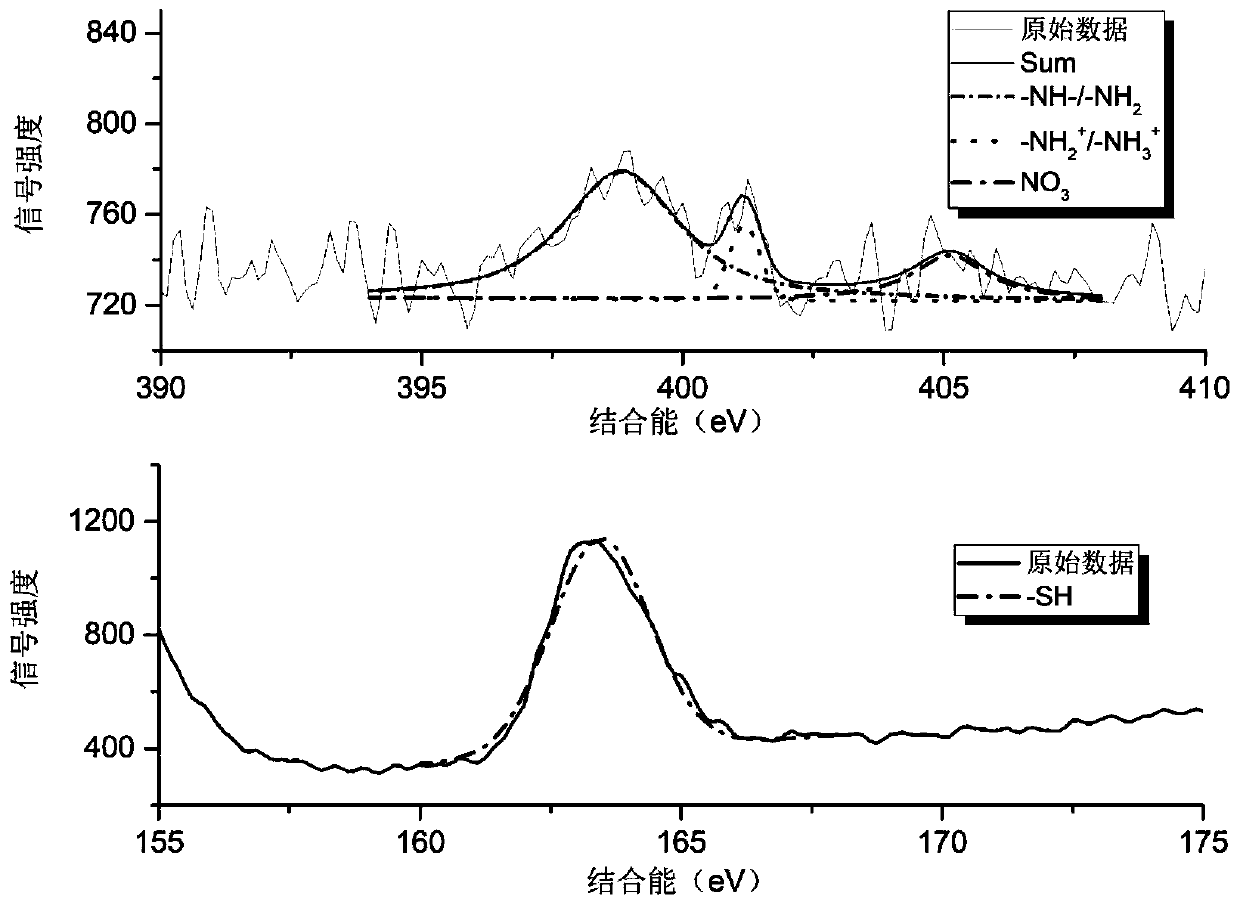

[0057] In this example, the preparation method of the mercapto-modified SBA-15 mesoporous silicon material is as follows:

[0058] Step 1, polyethylene oxide-polypropylene oxide-polyoxyethylene triblock copolymer (P123) and concentration are 2mol L by mass volume ratio 1:30 -1 Add hydrochloric acid into a glass Erlenmeyer flask, stir at 40°C for 2h until P123 is completely dissolved. Add tetraethyl orthosilicate (TEOS) dropwise to the mixed solution, stir at a rate of 350r / min for 60min to prehydrolyze TEOS, then add mercaptopropyltrimethoxysilane (MPTMS) dropwise and increase the stirring rate to 500r / min. The silicon contained in the added TEOS accounts for 5% of the moles of P123, and the mercapto groups contained in the MPTMS account for 30% of the total moles of silicon in the mixed solution. The above mixed solution was continuously stirred at 40° C. for 20 h, then transferred to a high-pressure reactor, and crystallized at 100° C. for 24 h. After the product is coole...

Embodiment 2

[0094] In this example, the preparation method of the mercapto-modified SBA-15 mesoporous silicon material is as follows:

[0095] Step 1, polyethylene oxide-polypropylene oxide-polyoxyethylene triblock copolymer (P123) and concentration are 2mol L by mass volume ratio 1:30 -1 Add hydrochloric acid into a glass Erlenmeyer flask and stir at 40°C for 4h until P123 is completely dissolved. Add tetraethyl orthosilicate (TEOS) dropwise to the mixed solution, stir at a rate of 300r / min for 60min to prehydrolyze TEOS, then add mercaptopropyltrimethoxysilane (MPTMS) dropwise and increase the stirring rate to 400r / min. The silicon contained in the added TEOS accounts for 5% of the moles of P123, and the mercapto groups contained in the MPTMS account for 30% of the total moles of silicon in the mixed solution. The above mixed solution was continuously stirred at 40° C. for 20 h, then transferred to a high-pressure reactor, and crystallized at 100° C. for 24 h. After the product is co...

Embodiment 3

[0103] In this example, the preparation method of the mercapto-modified SBA-15 mesoporous silicon material is as follows:

[0104] Step 1, polyethylene oxide-polypropylene oxide-polyoxyethylene triblock copolymer (P123) and concentration are 2mol L by mass volume ratio 1:30 -1Add hydrochloric acid into a glass Erlenmeyer flask and stir at 40°C for 4h until P123 is completely dissolved. Add tetraethyl orthosilicate (TEOS) dropwise to the mixed solution, stir at a speed of 400r / min for 60min to prehydrolyze TEOS, then add mercaptopropyltrimethoxysilane (MPTMS) dropwise and increase the stirring rate to 600r / min. The silicon contained in the added TEOS accounts for 5% of the moles of P123, and the mercapto groups contained in the MPTMS account for 30% of the total moles of silicon in the mixed solution. The above mixed solution was continuously stirred at 40° C. for 20 h, then transferred to a high-pressure reactor, and crystallized at 100° C. for 24 h. After the product is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com