Preparation method and application of single-atom copper material

An atomic, in-situ technology, applied in the field of single-atom copper materials, can solve the problems of complex preparation process, high cost, low yield, etc., and achieve the effect of overcoming the preparation process, suppressing the hydrogen evolution reaction, and increasing the ammonia yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

[0036] 1) Preparation of single-atom copper materials.

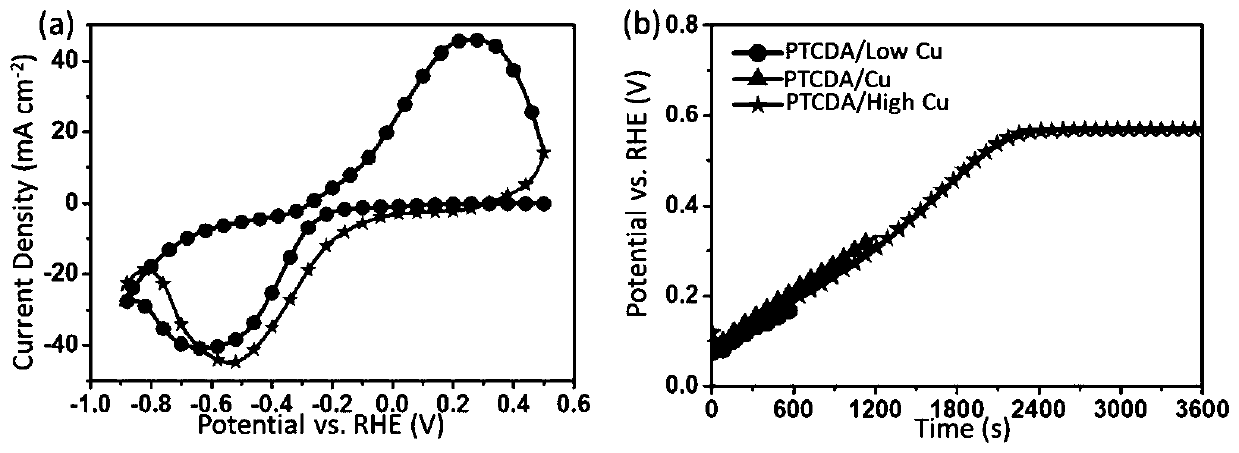

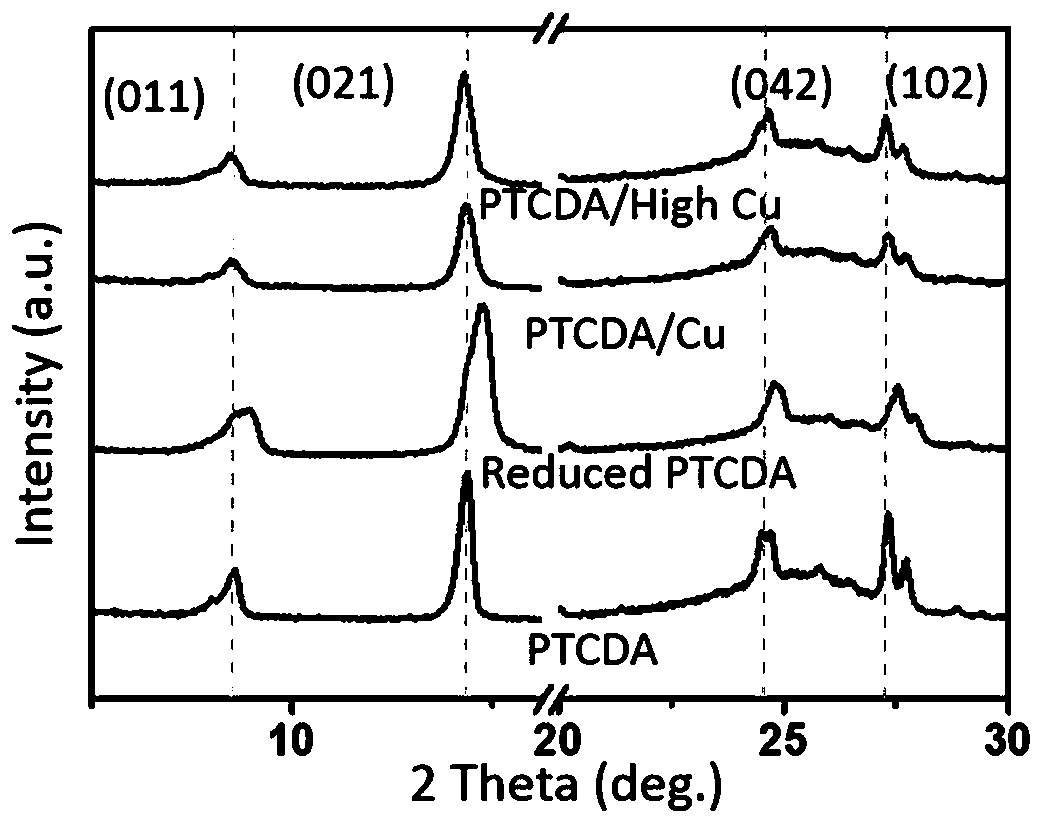

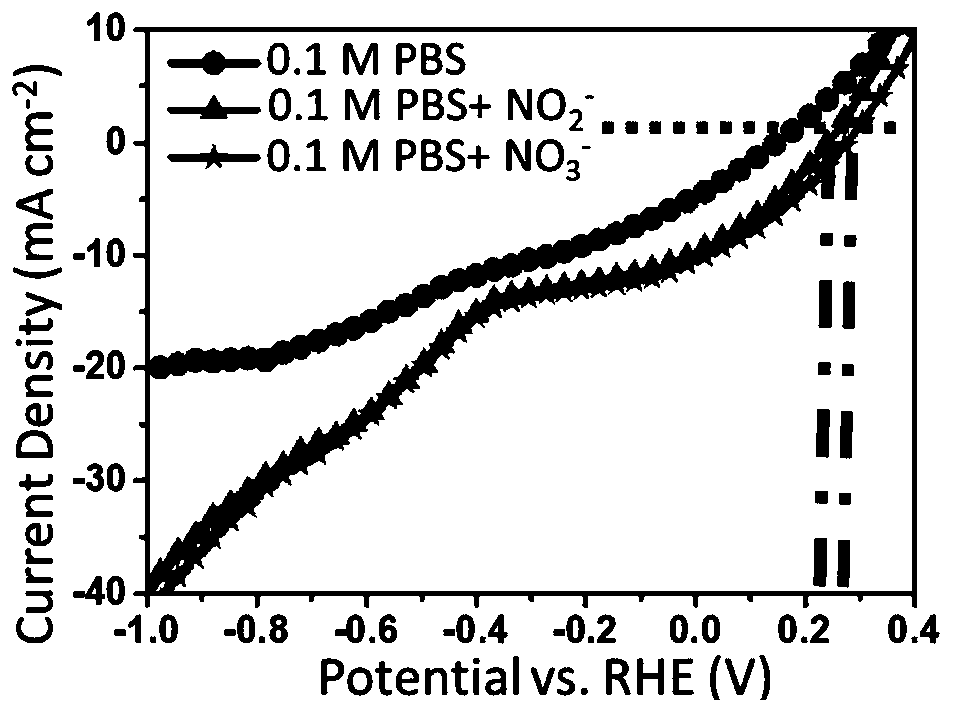

[0037] The inventor has studied: at first PTCDA is reduced, and make it incorporate hydronium ion (H 3 o + ). We recorded the cyclic voltammetry (CV) curves of PTCDA electrode in 1.0M HCl in a three-electrode electrolytic cell. In the first cycle, the cathode scan showed a reduction peak around -0.62V ( figure 1 a), corresponding to the reduction reaction of PTCDA and H 3 o + the incorporation process. During the subsequent anodic scan, an oxidation peak at +0.26V was observed. Thus, the electrodes exhibit re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com