Green and environment-friendly high-strength cosmetic glass bottle

A green and high-strength technology, applied in packaging cosmetics, glass molding, glass manufacturing equipment, etc., can solve the problems of cosmetic leakage, easy breakage, breakage, etc., achieve the effects of reducing pollution, not easy to break, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0057] A green and environmentally friendly high-strength cosmetic glass bottle, including a bottle body, the bottle body is in the shape of a cylinder. There is an internal thread, and the bottle cap is matched with the thread of the bottle mouth.

[0058] The bottle cap is made of polytetrafluoroethylene.

[0059] The bottle body is made of green and environmentally friendly high-strength glass.

[0060] Green environment-friendly high-strength glass comprises the following components among the embodiment 1-4:

[0061] Silica, waste glass, alumina, cesium sulfate, indium phosphide.

[0062] The input amount (unit Kg) of each component among the embodiment 1-4 sees table 2 for details

[0063] Table 2

[0064] Example 1 Example 2 Example 3 Example 4 silica 100 100 100 100 waste glass 20 25 30 26 Aluminum oxide 10 11 12 10.5 cesium sulfate 1 1.5 2 1.22 indium phosphide 0.3 0.4 0.5 0.33

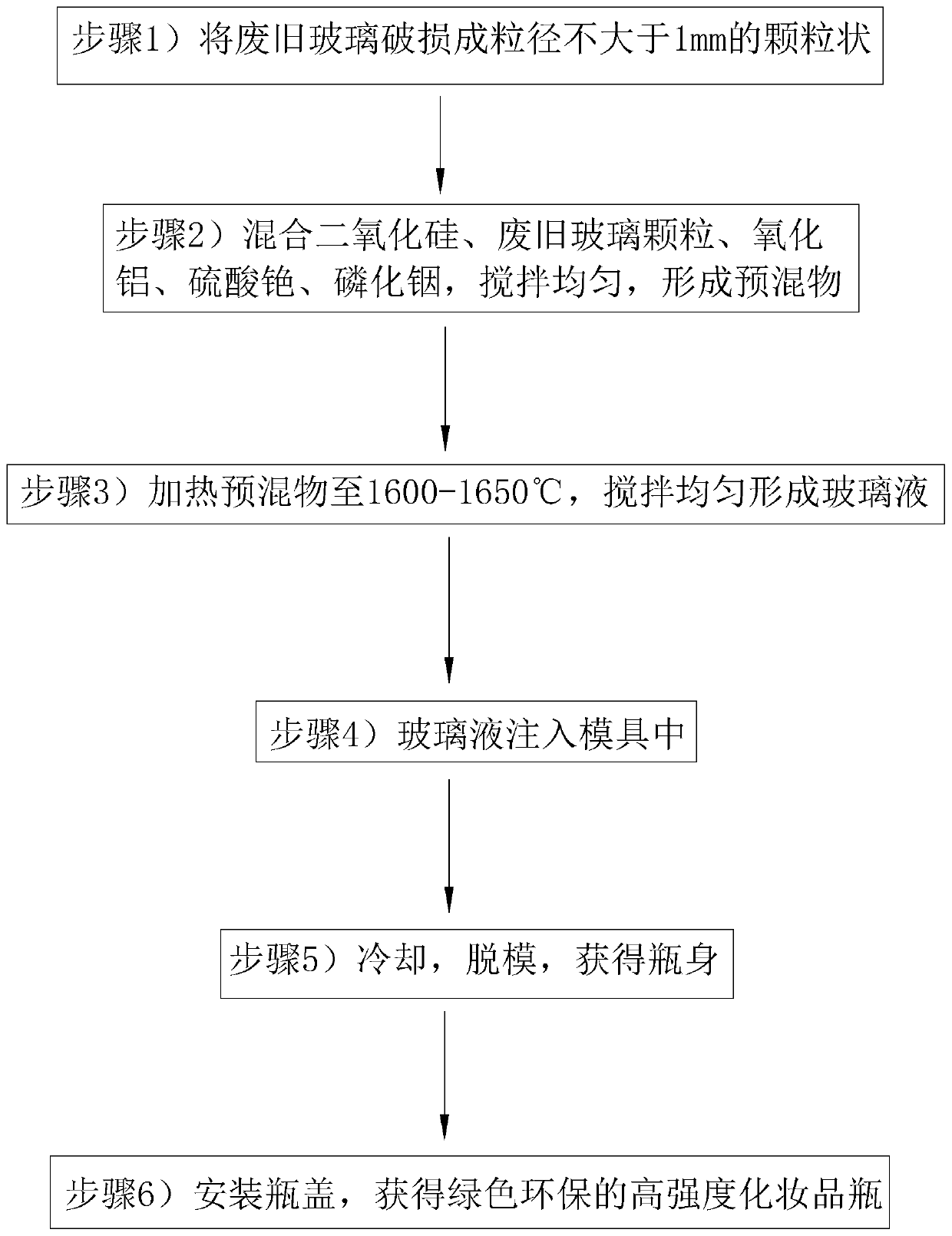

[0065] refer to fig...

Embodiment 5

[0073] Compared with embodiment 4, the difference only lies in:

[0074] In step 1), the waste glass is put into a crusher and broken into granules with a particle size of 0.5mm±0.1mm;

[0075] In step 3), heat the premixed mixture to 1600° C., rotate at 60 r / min, and stir for 3 minutes to form glass liquid.

Embodiment 6

[0077] Compared with embodiment 4, the difference only lies in:

[0078] In step 1), put the waste glass into a crusher, and break it into granules with a particle size of 0.1 mm ± 0.1 mm;

[0079] In step 3), heat the premix to 1650° C., rotate at 60 r / min, and stir for 3 minutes to form glass liquid.

[0080] The implementation principle of Examples 1-6 is: by first mixing silicon dioxide, waste glass, aluminum oxide, cesium sulfate, and indium phosphide to form a premix, so that the distribution of each group is uniform, so that when the premix is heated into glass liquid , The required stirring time is shortened, which is beneficial to reduce the high temperature stage, reduce energy consumption, and be environmentally friendly. At the same time, the components are evenly distributed, so that the performance of each part of the green and environmentally friendly high-strength cosmetic glass bottle is less different and the quality is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com