Method for recycling heavy components of methyl acrylate

A technology of methyl acrylate and heavy components, applied in chemical instruments and methods, preparation of carboxylic acid esters/lactones, preparation of organic compounds, etc., can solve problems such as difficult cracking process, waste of resources, affecting product quality, etc., and achieve reaction The process is smooth, avoiding carbonization and deterioration, and ensuring the effect of polymerization inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Take the raw material of methyl acrylate heavy component recovery process (methyl acrylate by-product heavy component), preheat to 100°C, and enter the thermal cracking reaction with methanol and water at a feed ratio of 100:5:3 in mass ratio device, the thermal cracking temperature is 130°C, the pressure is 80kpa, the reaction time is 2h, and the recovered gas phase light components enter the product collection tank through the heat exchanger;

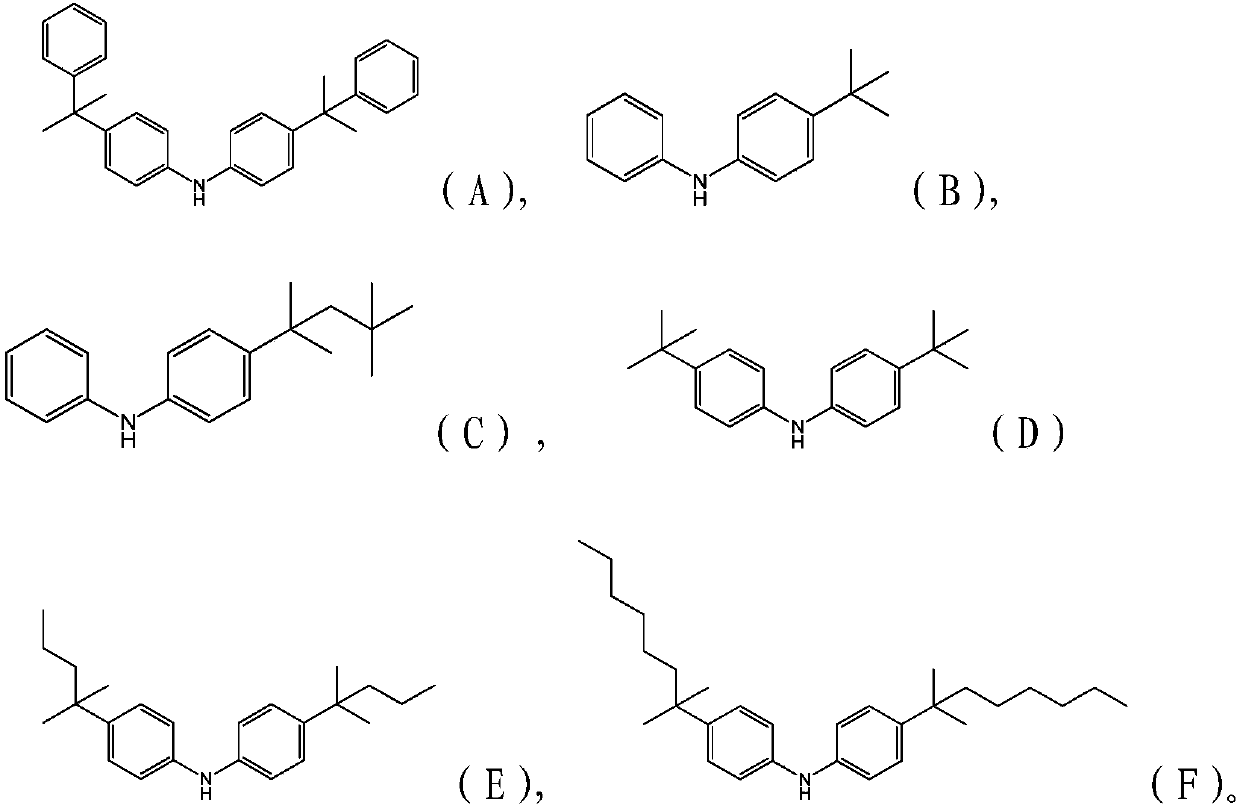

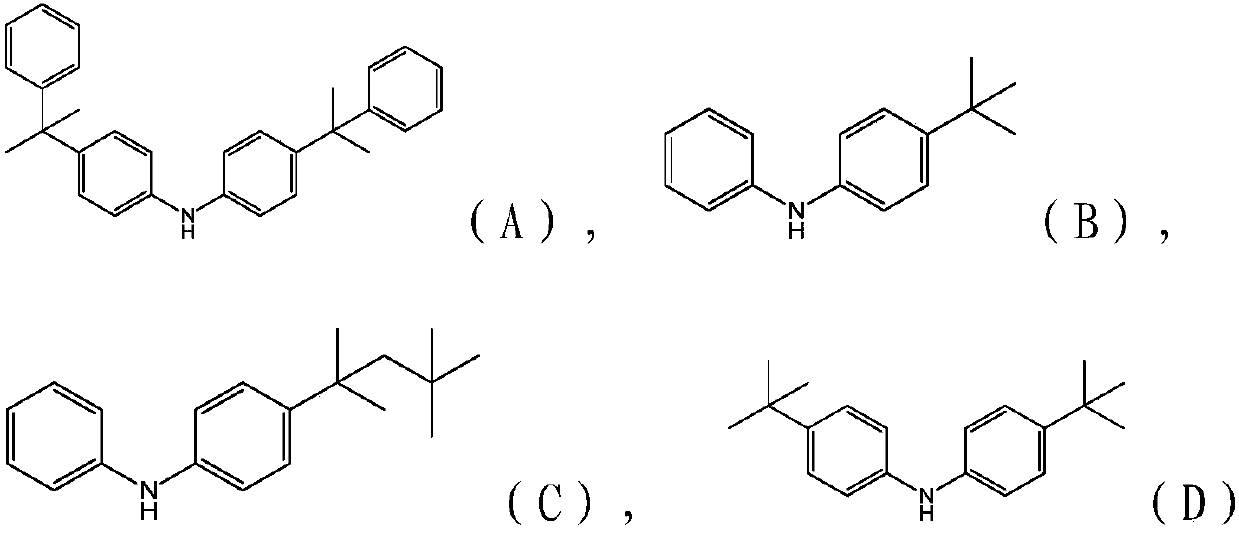

[0033] The heavy component obtained in the thermal cracking reactor and methanesulfonic acid are added to the catalytic cracking reactor in a mass ratio of 100:5, and the compound inhibitor (compound of formula (A) and (B) compound) is added to a total of 150ppm , the compound mass ratio of the two is 8:2, the catalytic cracking temperature is set to 180°C, the pressure is 80kpa, the reaction time is 2h, and the recovered gas phase light components enter the product collection tank through the heat exchanger;

[0034]...

Embodiment 2

[0037] Example 2 Take the raw material of methyl acrylate heavy component recovery process (methyl acrylate by-product heavy component), preheat to 110 ° C, and enter the thermal cracking reaction with methanol and water at a feed ratio of 100:7:5 in mass ratio device, the thermal cracking temperature is 140°C, the pressure is 80kpa, the reaction time is 2h, and the recovered gas phase light components enter the product collection tank through the heat exchanger;

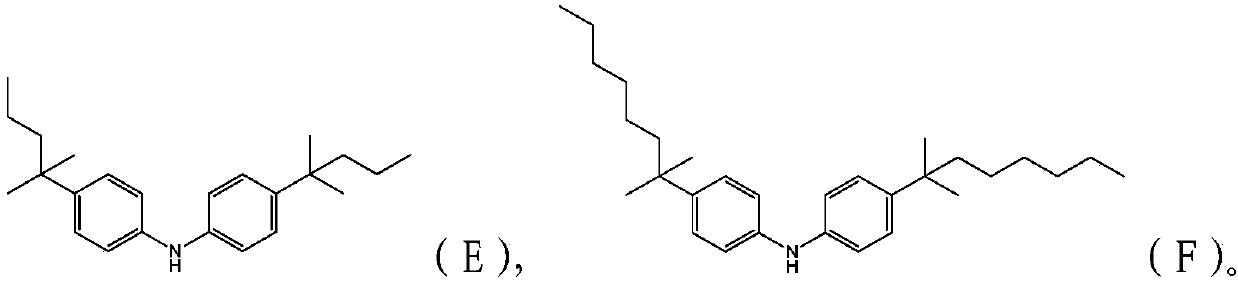

[0038] The heavy component obtained in the thermal cracking reactor and methanesulfonic acid are added to the catalytic cracking reactor in a mass ratio of 100:8, and the compound inhibitor (formula (A), (B) and (D) compound compound Mixing), a total of 180ppm, the compounding mass ratio is 6:2:2, the catalytic cracking temperature is set to 190°C, the pressure is 80kpa, the reaction time is 2.5h, and the recovered gas phase light components enter the product collection tank through the heat exchanger;

[0039] The ...

Embodiment 3

[0042] Example 3 Take the raw material of methyl acrylate heavy component recovery process (methyl acrylate by-product heavy component), preheat to 110 ° C, and enter the thermal cracking reaction with methanol and water at a feed ratio of 100:10:8 in mass ratio device, the thermal cracking temperature is 140°C, the pressure is 80kpa, the reaction time is 2h, and the recovered gas phase light components enter the product collection tank through the heat exchanger;

[0043] The heavy component that obtains in the pyrolysis reactor and methanesulfonic acid are in mass ratio 100:10, join catalytic cracking reactor, add compound inhibitor (formula (B), (C), (D) and ( E) compound compound) totals 180ppm, compound mass ratio is 3:3:2:1, catalytic cracking temperature is set to 210°C, pressure is 80kpa, reaction time is 3h, recovered gas phase light components enter through heat exchanger product collection tank;

[0044] The heavy components obtained in the catalytic cracking react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com