Super absorbent resin/kaolin composite sphere moisture absorption material with shell-core structure and preparation method thereof

A technology of super absorbent resin and hygroscopic material, applied in the field of composite hygroscopic materials, can solve the problems of small capacity, low efficiency, slow moisture absorption rate, etc., and achieve the effects of large water storage capacity, increased specific surface area, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Such as Figure 7 Shown is the preparation process flow chart of the present invention. It includes the following steps

[0038] S1 activation: kaolin is suspended in saline solution for activation, then dried and ground to obtain activated kaolin;

[0039] S2 swelling: the spherical superabsorbent resin is immersed in deionized water to absorb water and swell;

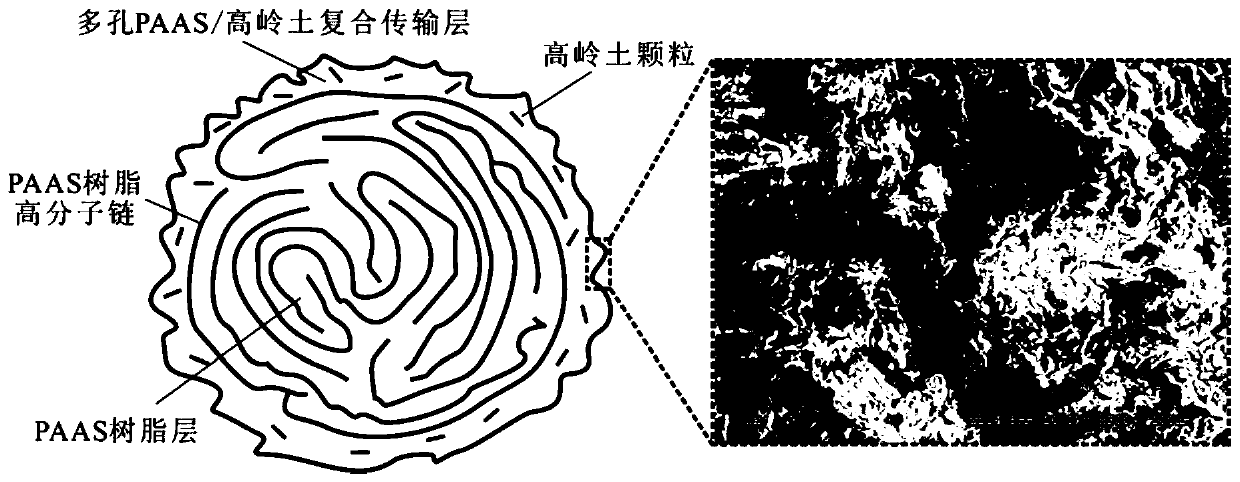

[0040] S3 coating: the swollen superabsorbent resin is taken out by water filtration, and then mixed with activated kaolin, so that the activated kaolin is evenly coated to obtain coated particles;

[0041] S4 drying and sieving: drying the coated particles until the surface hardens, and at the same time, a small amount of activated kaolin powder will fall off from the surface of the dry particles, and sieving is performed to remove the excess kaolin that falls off, and obtain a shell-core structure superabsorbent resin / kaolin Composite ball hygroscopic material.

[0042] The details of the present inventio...

Embodiment 1

[0044] Take kaolin with a particle size of 80um and suspend it in saturated sodium chloride salt solution for 2.5 hours, then dry and grind to obtain activated kaolin. Take the superabsorbent resin ball and immerse it in deionized water to swell for 1 hour, then take out the swollen ball by filtering and drying it, and blend it with activated kaolin at a mass ratio of 1:30, so that the activated kaolin is evenly coated on the surface of the ball. Coating time was controlled within 10 minutes; then dried at 110°C for 4 hours, and the dried product was sieved to remove excess kaolin powder to obtain shell-core structure PAAS / kaolin composite spherical hygroscopic material PK8-25-1. The average particle diameter of the composite balls is 0.657 cm, and the content of kaolin in the composite particle balls of this embodiment is 26.08%.

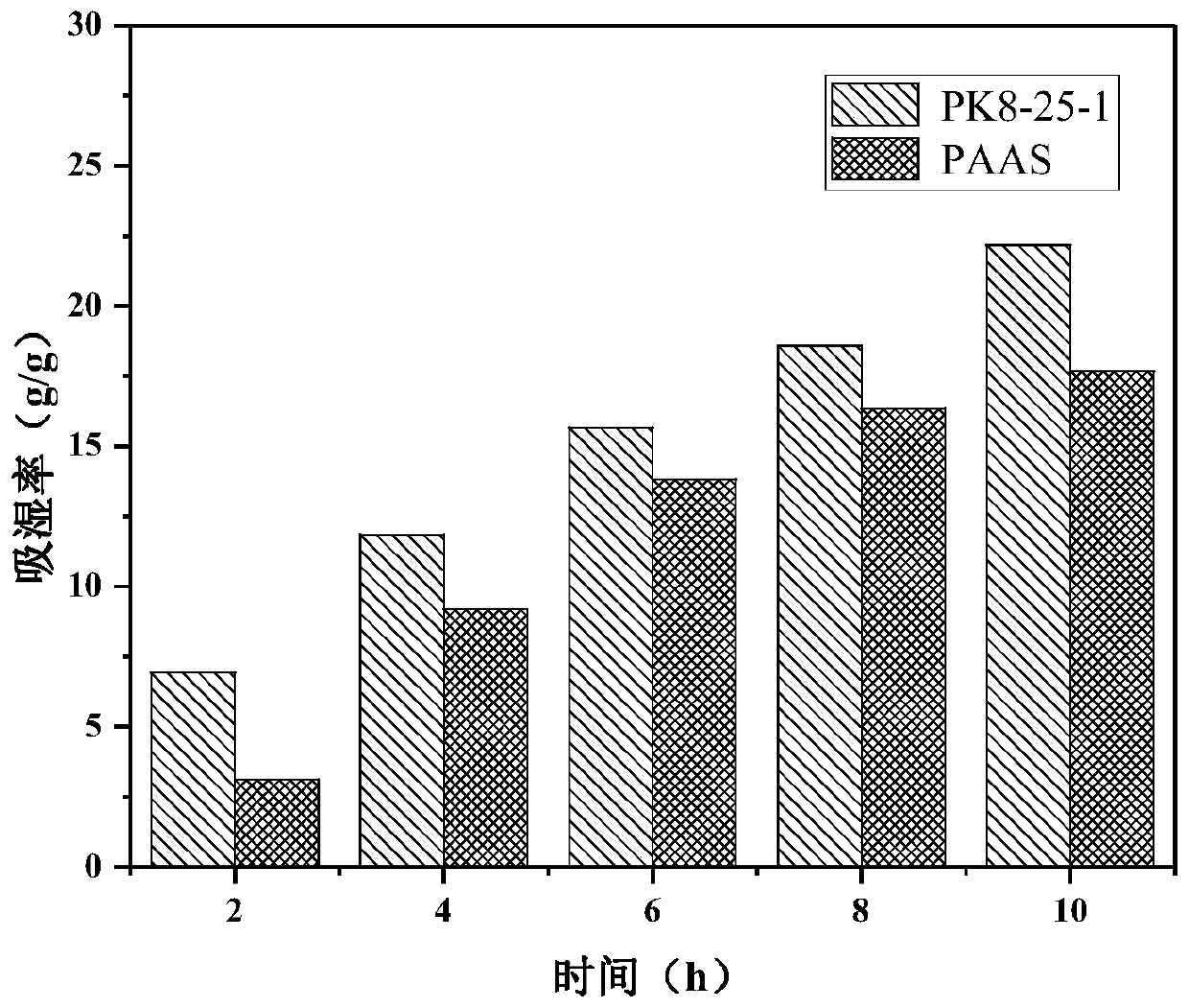

[0045] figure 2 It is the moisture absorption curve measured by PK8-25-1 and pure resin balls under the conditions of constant temperature 30°C, h...

Embodiment 2

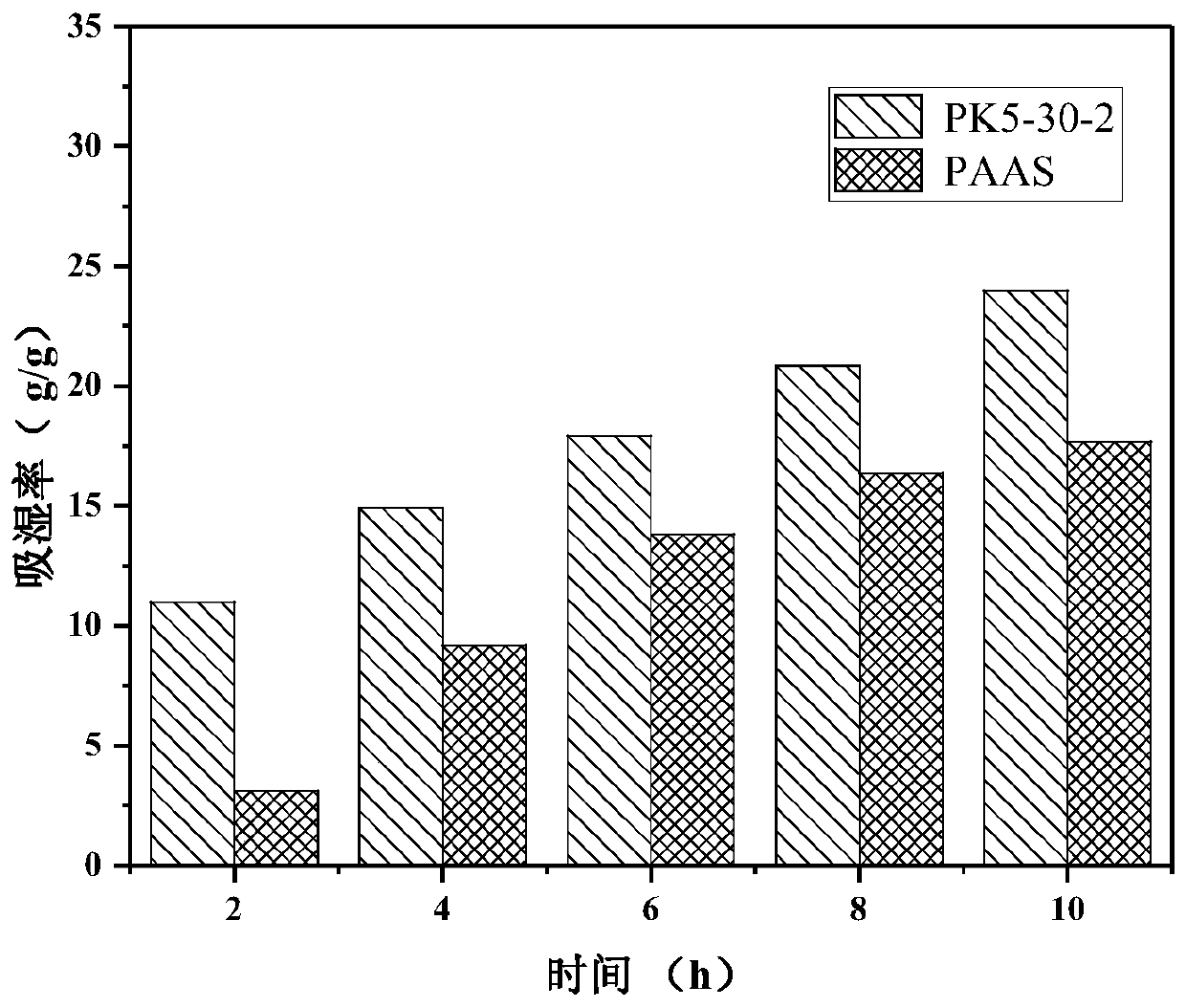

[0047] Take kaolin with a particle size of 50um and suspend it in a saturated salt solution for 2.5 hours, then dry and grind to obtain activated kaolin. Take the superabsorbent resin ball and swell it in deionized water for 2 hours, then take out the swollen ball by filtering and drying it, and blend it with activated kaolin at a mass ratio of 1:20, so that the activated kaolin is evenly coated on the surface of the ball. Coating time was controlled within 10 minutes; then dried at 120°C for 2 hours, and the dried product was sieved to remove excess kaolin powder to obtain shell-core structure PAAS / kaolin composite spherical hygroscopic material PK5-30-2. The average particle diameter of the composite balls is 0.457 cm, and the content of kaolin in the composite particle balls of this embodiment is 29.16%.

[0048] The moisture absorption capacity and moisture absorption rate of PK5-30-2 are 1.36 times that of pure resin balls, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com